my first cnc machine Jaime needs to choose a CNC Machine to start a business, and Bob shows her exactly how to go about it.CNC Router Buyer's Guide: https://www.cnccookbook.com/. $58.00

0 · when did cnc machining start

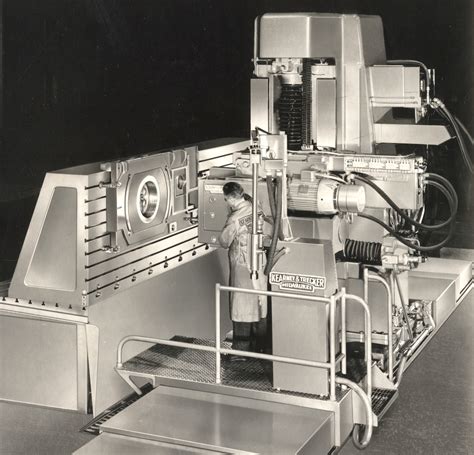

1 · john t parsons cnc machine

2 · james parsons cnc

3 · history of cnc machine pdf

4 · first cnc milling machine

5 · evolution of cnc machines

6 · cnc router history

7 · cnc machine history timeline

Junction boxes - Installation material - WISKA - make power smile WISKA Deutschland WISKA America WISKA Brasil . Junction boxes. Plastic. Plastic. Brass. Brass. Stainless steel. Stainless steel. Aluminium. Aluminium. Your contact Product finder 24h Spare part availability Request Information Brass surcharge.

when did cnc machining start

Getting Started: Machine Setup. Setting up your first CNC machine might seem daunting, but breaking it down into manageable steps can simplify the process. Step 1: Choose Your . Jaime needs to choose a CNC Machine to start a business, and Bob shows her exactly how to go about it.CNC Router Buyer's Guide: https://www.cnccookbook.com/.

john t parsons cnc machine

When you’re buying your first CNC machine, there are a lot of things to consider. So, we put together a guide that includes everything you need to know from when you’re purchasing your .

A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling .

"Buying my first CNC machine was absolutely terrifying – but it changed everything." In this video, Cory shares his personal journey of taking a huge financial risk to buy his first.

What It’s Really Like to Buy Your First CNC Machine? “Buying my first CNC machine was absolutely terrifying – but it changed everything.” In this video, Cory shares his .

My First CNC Machine: This CNC was created using parts bought though the Kickstarter project www.aquickcnc.com. Here is the Ended Kickstarted Project https://www.kickstarter.com/projects/ajquick/cnc-b. The Design was built . To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.

I have been looking around for machines under this mark and I have narrowed it down to 2 options: WorkBee CNC 1500x1500mm from Bulk Man 3d OR Mega V Router 19''x19'' from Millright. Which one do you guys think would be better as .

james parsons cnc

Dan Maloney. December 5, 2018. Despite appearances, [This Old Tony]’s latest series has little to do with CNC-ifying an Etch A Sketch. Although he certainly achieves that, more or less,. Ok, Here's a picture of my first CNC machine. And here's some specs. Work area is 15"X28" The motors are Xylotex 425oz/in I've got to upgrade the tool head and install the electronics but the major work is done. I built this for a cheap solution to drill holes in plastic and etch PCB's I did not follow any specs, I used a skill saw and hand drill. Thats why there is allot .I'm completely new to cnc and am wondering what I'm possibly doing wrong. [EDIT] My new set of bits arrived. Turns out the ones I was using (which were the only ones that came with the machine - v-bits) were only for engraving 😅. The .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc Members Online • [deleted] . Hi everyone, I am a new to cnc in general and I'm about to buy my first machine, at first I was leaning towards a .

My first CNC cutting machine was a bastard goose-sized monstrosity of spare oak wood, drawer slides, decking screws, NEMA17's and 3d printer shield. It could not cut. It could draw with a pen. My next was a makerslide based belt driven thing. It could cut soft wood with a dewalt router, hardwood very slowly.First CNC I am in the market for my first CNC. My budget is around 400 dollars. I typically make cutting boards and would like to engrave them. . There aren't many CNC machines that big that are that cheap, so you don't have a lot to select from. It's going to be a Chinese-made machine that's cut a few corners somewhere - you'll only find out .The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls. Early efforts involved analog computers and punch-card systems to control machine movements.

A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc

First, the machine. it is a generic machine from aliexpress. It is very cheap, about 300 NZD (just over 200 USD) including fast shipping. Assembly was not very difficult, although the instructions sometimes have measurements from smaller machines. . My first CNC - a small 3018 chinese cheap machine

I'm based in Europe and about to pull the trigger on ordering my first CNC machine. I'm a hobby woodworker/furniture maker/designer and I'm trying to step up and do it semi-professionally. I'll be cutting plywood, hardwoods and also aluminium so I .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . ADMIN MOD Advice for first CNC machine purchase . Sorry for the very boring post. I'm looking to get my first CNC (for woodworking). I don't have a lot of interest in spending a ton of time upgrading / modding etc so I'd like a solution that works . Jaime needs to choose a CNC Machine to start a business, and Bob shows her exactly how to go about it.CNC Router Buyer's Guide: https://www.cnccookbook.com/.This will be my first CNC machine. I've heard FoxAlien is a pretty decent brand for the price point - looking to spend under 00 (not counting accessories and QoL addons). I'm a professional 3D artist, graphic designer, and competent woodworker.

I'm about to get my first CNC machine to enhance my offerings as a custom furniture maker. The Axiom I'm buying comes with V-Carve Pro -- which I'll use for CAM -- but I'm considering three options for the CAD side. Learn V-Carve Continue using Sketchup which I'm already familiar with.This would be my first CNC machine, and the product that I am interested in manufacturing is a balisong (butterfly knife) trainer. I got my associates degree in Mechanical Engineering Technology but I have been working on the quality side (CMM programming) so I honestly forget most of the stuff I learned about CNC.

Genmitsu CNC Machine PROVerXL 6050 Plus for Metal Wood Acrylic MDF Carving, GRBL Control, 3 Axis Milling CNC Router Machine, Hybrid Table, Working Area 600 x 500 x 115mm (23.62" x .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . Overall this is probably the best first time design attemp that I've seen, so kudos for doing your research. I'd personally recommend looking .I've bought several. The ez-trak and proto trak mills were developed as cnc mills for old manual guys. Once you know how to run a CNC they really lose their appeal. I'd avoid a Haas but that's me. They are shit IMO. I'd buy the best condition Japanese machine I could find. With a Fanuc control. A 15 yo Mori or Kitamura would be my first choice.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

200a electrical splitter box

Hi all, As I found that there is very little information about these machines, I thought that a thread detailinh my path through installing and using it will be helpful. First, the machine. it is a generic machine from aliexpress. It is very cheap, about 300 NZD (just over 200 USD) including fast shipping. Assembly was not very difficult, although the instructions .

Very capable. Does require building. First job after first cuts is to make aluminum replacement parts for all the 3d printed parts. But it is a daunting task, usually a second or even third cnc. For me first aluminum extrusion based cnc, like a C beam with linear rails or on YT "Core3d_tech" Extrusion CNC. Then PrintNC_mini. “Buying my first CNC machine was absolutely terrifying – but it changed everything.” In this video, Cory shares his personal journey of taking a huge financial risk to buy his first machine and how it launched his machining business. If you’re thinking about buying your first machine and feeling overwhelmed by the cost, the unknowns, or .

As I see now that there are a lot of hobbyist CNC machines in the sub 2k, 1k, and 500 range, I was wondering about the feasibility of getting a CNC to produce things like the following: So while these are all laser cut, I'm much more interested in owning a CNC vs a Laser, and I think it'd be a lot easier to integrate into my apartment.

history of cnc machine pdf

My first CNC milling machine is finally coming true after some work. The basic frame was bought by Sorotec as a kit. All other parts were bought together independently. For the movement I use JMC servos with integrated drivers.CNC is faster than 3d printing for sure, but I can’t just walk away from it like I do my 3d printer, either. Also, I probably have 0 total in each of my 3d printers. I probably have two racks tied up in my cnc if you include the accessories, end mills, enclosure and table. I .

first cnc milling machine

In this video I will walk you through some very simple steps to make your first cuts on a CNC machine. In February I got the Axiom AR8 Pro from my good frien.I’m looking for my first CNC machine to help me learn CAM using Fusion 360 and in the processor learn how to machine aluminum, as it’ll add to my skill set at work. I have a limited budget, roughly £600 atm. I’m aware of the company’s like sainsmart/ foxalien and also carbide 3d. Hello everyone. I am here looking for some help/advice. I have been researching my first CNC, and have spent countless hours on line, exchanging emails with machine/tool suppliers, reading forums, and trying to digest reviews. First and foremost I am a home user, with a garage converted into a heated shop space. I have looked at numerous brands and models, .

evolution of cnc machines

EMT allows use of normal size wires with up to 4 circuits per conduit (the equivalent of 8 if you use multi-wire branch circuits). 1/2" EMT is easy to work with, cuts with any hacksaw, deburrs with your multi-tool stripper, and the fittings are dirt cheap. Combine that with $1.00 Handy-boxes or 4x4 boxes, and it's easy going.

my first cnc machine|when did cnc machining start