sheet metal products examples History. Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The process of flattening metal sheets required large . $8.56

0 · what is sheet metal used for

1 · what is a sheet metal

2 · what are sheet metal parts

3 · types of sheet metal parts

4 · types of sheet metal fabrication

5 · sheet metal forming examples

6 · sheet metal construction materials

7 · examples of sheet metal

Performance MRP mass air flow Housings utilize an open cell, honey comb, air flow straightener to create a laminar air flow and significantly reduce turbulence at the MAF sensor.

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a . This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more.

History. Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The process of flattening metal sheets required large . Sheet metal is required across many industries, from automotive to aerospace, construction to electronics. The wide range of materials it offers, such as aluminum, steel, and copper, lends to its versatility, each providing .

If you’re considering metal for a project, you’ll need to know some of the main options available for fabrication. Some of the most common materials used in metal fabrication are: Black iron sheet: A black iron sheet is an ideal .

Laser cutting, twisting, hole punching, cold sheet metal stamping, spot welding, automated MIG-MAG welding, TIG welding, powder dyeing. Cold sheet metal stamping. One of the most popular methods for sheet metal processing is cold .The best Sheet Metal Worker Resume Examples with Headline, Objective statement, Description and Skills. Download Sample Resume Templates in PDF, Word formats. . Installed sheet metal products and equipment in accordance with company standards. Resolved issues with metal- working machinery and tools.Sheet metal can be used to create shelters for all kinds of different things. Whether it is for people or animals, you can use sheet metal to create a variety of different kinds of shelters. 7. Facades. Facades are another popular .We’ve made it easy for you to build your Sheet Metal Fabricator SOPs – either take the below SOP outlines and craft your own set of SOPs or save 10+ hours of research, cross-referencing, typing and formatting and purchase a 5,000+ word set of cross-referenced starter SOPs that include the most common SOPs used by a Sheet Metal Fabricator.

Galvanized sheet metal: . To give you a better idea of the most common uses of metal in the industry, consider a few examples of metal fabricated products below: Utensils: When you’re looking for products made from metal, look no further than a kitchen drawer. Forks, knives and spoons are all regularly made out of stainless steel and other .A highly experienced Sheet Metal Mechanic with over 15 years of industry experience, specializing in the installation and repair of metal products and structures. Possessing excellent problem- solving skills, thorough knowledge of metal fabrication techniques, and strong attention to . Post-processing, metal laser engraving, CNC wire bending, sheet metal bending, cutting, and shaping are inclusive of Evans Manufacturing services. Evans Manufacturing For Metal Fabricated Products. We produce higher quality and specialized solutions for your needs using our knowledge, state-of-the-art technology, and dedication to perfection.Sheet Metal Worker Resume Samples and examples of curated bullet points for your resume to help you get an interview. . construction, and repair of sheet metal products and equipment typical to the sheet metal trade in all types of buildings, facilities substructures, infrastructures, superstructures and parts thereof for University, College .

Find the best Sheet Metal Worker resume examples to help improve your resume. Each resume is hand-picked from our database of real resumes. . Programed many sheet metal products using C.A.D./C.A.M. technology; 10+ years of experience. Supervises, coordinates and participates in the construction, installation, alteration and repair of sheet .

A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made from sheets of metal. Their direct supervisor may be a sheet metal supervisor, shop manager, production manager, or general contractor depending on their place of employment. Examples of sheet metal parts include chimneys, sheet metal furnaces, and automobile shells. Sheet metal processing involves the use of metal plates to create parts such as chimneys, iron drums, oil tanks, ventilation pipes, elbow heads, round places, funnel shapes, and .For example, copper thickness is measured in ounces, which represents the weight of copper contained in a one-square-foot area. Parts made from sheet metal must maintain a consistent thickness for best results. . This type of sheet metal is ideal for products that will be exposed to frequent moisture. It contains chromium, an element that .Abstract: Design of sheet metal products can be a complex and elaborate process. However, many important aspects of the manufacturing characteristics of a . Examples from a working implementation are shown. Keywords: sheet metal, flat pattern, conceptual design, sketch, expert system. 1. Introduction

Precise Metal Products Specializes in Sheet Metal Fabrication & Machined Components for the Aerospace, Power Generation and Military Industries Past Project Examples APU Exhaust Tailpipe Plenum Housing Inlet Plenum APU Plenum APU Bell Inlet APU Exhaust Liner Certifications & Purchase Order Terms & Conditions. 8 Everyday Products Made From Metal Stamping Metal stamping has roots dating back to the 1800s, when it started to replace inconsistent and time-consuming manufacturing processes like die forging. Fast forward to today, and you’ll find metal-stamped products of all shapes and sizes everywhere — some of which you use on a daily basis. sheet metal drawing examples sheet metal drawing examples. Taking a simple sheet metal part as an example, although its structure is relatively straightforward, the drawing process is relatively easy. However, .We can look at a few examples. Sheet metal products are found in many industries such as the automotive industry, which is representing the frames, parts of the controls, bodies, or perhaps exhausts. These products must be .

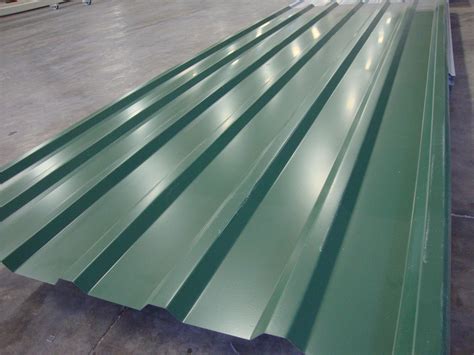

Sheet metal prototype examples. Let’s see some real-world Applications of sheet metal prototyping; 1. Electrical Enclosures. Stainless steel, aluminum prototyping, or other similar low-weight sheets are used in electrical .Some examples of products that use sheet metal are car bodies, airplane wings, kitchen utensils, and metal roofs. Sheet metal stock is specified by the dimensions of the sheet, the type of material, and the gauge. The gauge is a measure of the thickness of the sheet metal, and it varies depending on the material. For example, a 14-gauge steel .

Laser engraving allows manufacturers to leave a fine, but distinctive mark on their sheet metal products. . These cutouts are then used as small, flat parts for other products. For example, small cutouts could be made into computer drive mounts or miniature fan blades with additional work using a CNC press brake or other metal forming .

The best way to gain knowledge on the topic is by diving into real-world examples. In this article, we’ll explore seven prime roll forming products that you may not realize are roll formed parts. 7 METAL ROLL FORMING PRODUCTS IN DISGUISE. Roll forming products are all around you. Just look at the buildings and infrastructure you pass by every .

The International Organization for Standardization (ISO) provides globally recognized standards in sheet metal fabrication through ISO 2768-1:1989. It outlines general tolerances for various aspects of sheet metal parts, including: Linear Dimensions: This category includes tolerances based on the nominal length ranges in millimeters. There are .

Sheet metal forming is a manufacturing process that involves shaping thin metal sheets into desired geometries through techniques like bending, stretching, and deep drawing. This versatile process is widely used in industries such as automotive, aerospace, and construction, due to its efficiency in producing lightweight and durable components.. Familiarizing yourself with sheet . Design sheet metal products so hardware can be easily applied and performance optimally; . Screws, for example, can be inserted with a precise level of torque, whereas there’s much more variability in rivet application. Screws. Screws are high strength fasteners that can be removed for repair or maintenance. They also do this without the .

For example, if you need specially shaped holes, cutting with punches and dies would be best. Shearing tools are also useful for cutting off small unwanted slithers in a straight line. . To start making products yourself using sheet metal forming, you’ll need to make a hefty initial investment for all the equipment and tools needed (unless .

lame metallic metal fabric

Any flat metal with a thickness of 0.150 to 6mm (0.006 to 0.25”) is known as sheet metal. These sheets are used to form a variety of parts and products using various metal forming techniques. Oct. 01, 2020 Our new product "FeLuce TM" (hairline-finished electroplated steel sheet) wins the Good Design Award 2020 ~Our first steel sheet to win the Good Design Award~ Feb. 14, 2019 NSSMC Receives Shell’s Supplier Award; Jul. 30, 2018 Execution of Strategic Partnership with BP Oman Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc.

what is sheet metal used for

what is a sheet metal

RLR fabricates the best chassis kits in the volkswagen world. Made out of 4130 Chromoly steel. (This item is crated and ships by truck freight. Crate charge will apply. If you have trouble ordering, please call.) Made to order. *

sheet metal products examples|types of sheet metal fabrication