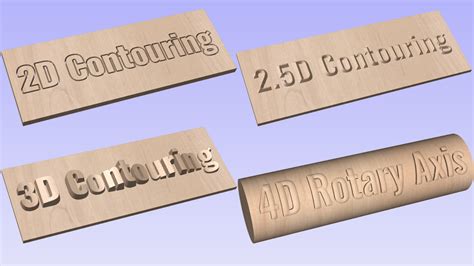

abbreviation for cnc machine CNC terminology guide: This guide explains the common terms and acronyms used in CNC machining, such as axes, offsets, speeds, and tools. CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

0 · what is 2.5d cnc

1 · what does cncs stand for

2 · cnc terminology pdf

3 · cnc milling terminology

4 · cnc machining terminology

5 · cnc machine stands for

6 · cnc machine acronym

7 · cnc abbreviation means

In the IEC system, "Ex e" is a specific designation that indicates that equipment is built to the requirements of the Increased Safety method of protection. With this, the design is .

CNC terminology guide: This guide explains the common terms and acronyms used in CNC machining, such as axes, offsets, speeds, and tools. CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to .What is CNC: CNC stands for computer numerical control, which is a process of .To help you easily reference common CNC machine abbreviations, we've compiled a cheat sheet that includes frequently used codes, functions, and parameters. Keep this cheat sheet handy .CNC stands for “Computer Numerical Control”, and refers to a manufacturing method based on the automation and precise control of machine tool movements through the use of pre .

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer.Learn how CNC machines can speed up your making process and turn 2D or 3D designs into a wide range of parts and products. CNC is an abbreviation for “Computer Numeric Control,” a term that encompasses a large family of .

The abbreviation CNC primarily stands for Computer Numerical Control, a technology used in manufacturing that automates machine tools via a computer, enhancing precision and .

CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their . CNC stands for Computer Numerical Control, a manufacturing method that automates machine tools through preprogrammed software. CNC machines work by following instructions and parameters set in the program, . CNC (Computer Numerical Control) machining uses computers to control and monitor the movements of a machine tool during the manufacturing process. Depth of Cut denotes how much material is being removed from a . CNC terminology guide: This guide explains the common terms and acronyms used in CNC machining, such as axes, offsets, speeds, and tools. CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to control the movement and operation of machine tools.

To help you easily reference common CNC machine abbreviations, we've compiled a cheat sheet that includes frequently used codes, functions, and parameters. Keep this cheat sheet handy for quick access to important information during your CNC machining endeavors.CNC stands for “Computer Numerical Control”, and refers to a manufacturing method based on the automation and precise control of machine tool movements through the use of pre-programmed computer software integrated into these tools.Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

Learn how CNC machines can speed up your making process and turn 2D or 3D designs into a wide range of parts and products. CNC is an abbreviation for “Computer Numeric Control,” a term that encompasses a large family of machines used by makers.

The abbreviation CNC primarily stands for Computer Numerical Control, a technology used in manufacturing that automates machine tools via a computer, enhancing precision and efficiency. It can also refer to other contexts such as Council of National Clinical Societies in . CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing. CNC stands for Computer Numerical Control, a manufacturing method that automates machine tools through preprogrammed software. CNC machines work by following instructions and parameters set in the program, allowing for precise and accurate operations. CNC (Computer Numerical Control) machining uses computers to control and monitor the movements of a machine tool during the manufacturing process. Depth of Cut denotes how much material is being removed from a work piece with each pass of the tool. Scans and maps the surface of a real object, producing a 3D computer model for CAD/CAM programs.

CNC terminology guide: This guide explains the common terms and acronyms used in CNC machining, such as axes, offsets, speeds, and tools. CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to control the movement and operation of machine tools.To help you easily reference common CNC machine abbreviations, we've compiled a cheat sheet that includes frequently used codes, functions, and parameters. Keep this cheat sheet handy for quick access to important information during your CNC machining endeavors.CNC stands for “Computer Numerical Control”, and refers to a manufacturing method based on the automation and precise control of machine tool movements through the use of pre-programmed computer software integrated into these tools.Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Learn how CNC machines can speed up your making process and turn 2D or 3D designs into a wide range of parts and products. CNC is an abbreviation for “Computer Numeric Control,” a term that encompasses a large family of machines used by makers.

The abbreviation CNC primarily stands for Computer Numerical Control, a technology used in manufacturing that automates machine tools via a computer, enhancing precision and efficiency. It can also refer to other contexts such as Council of National Clinical Societies in .

CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.

CNC stands for Computer Numerical Control, a manufacturing method that automates machine tools through preprogrammed software. CNC machines work by following instructions and parameters set in the program, allowing for precise and accurate operations.

how much will it cost to build a metal house

what is 2.5d cnc

what does cncs stand for

The result is that large electric motors and other equipment like that will have power factor compensation equipment. But it has to set up so it matches your equipment. So a power saver .

abbreviation for cnc machine|what does cncs stand for