electric box at service wire How many watts is the capacity of number 4 service wire.? - 2021-09-06 by Nestor - . Stamping Process in Sheet Metal. The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including dies tailored for precision and repeatability.

0 · types of electrical service panels

1 · residential main electrical panel

2 · residential electrical service panels

3 · residential electrical panel boxes

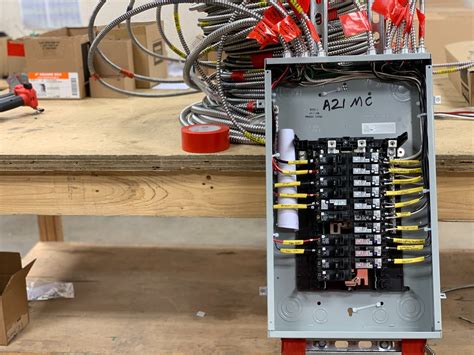

4 · inside electrical panel box

5 · electrical service panel location

6 · electrical service panel list

7 · best service panels for residential

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more

Electrical service entry wiring, service entry cabling (SEC), & the electrical meter: how to inspect for & report service ampacity, service entry defects & hazards. Carson Dunlop Associates' sketch at page top shows where the electrical inspection starts at a residential property.

This page gives the necessary increase in electrical service entry wire size for long .

types of electrical service panels

residential main electrical panel

How many watts is the capacity of number 4 service wire.? - 2021-09-06 by Nestor - . Iirc, the electrical code typically calls for #3 or #4 gauge wire on each phase for 100Amp service. You'd likely need one sensor on each phase .Wiring a panel box is an essential skill for any homeowner or aspiring electrician. It involves connecting the electrical service entrance wires to the breakers and circuits in the panel box, ensuring safe and efficient distribution of electricity . In most jurisdictions, homeowners can install their own electrical service as long as they do the homework, pull the permit, and collaborate with the inspector and the utility company. Changing out an energized, existing .

Installation of 100 amp electric service or subpanel needs a #4 AWG copper wire or #2 AWG aluminum or copper-clad wire inside a minimum 1.25 inch, schedule 40 or 80 PVC electric conduit for underground service. Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that . The electrical service masts should not be more than 3-f eet vertically above the roof line; most utilities will require bracing or guy wires for additional support of any mast that is taller than 3-feet. Understand the basics of your home's electrical service panel to keep you safe and your home well-lit and energized. The electrical panel connects the external electrical wires to the home's internal electric system.

Electrical service entry wiring, service entry cabling (SEC), & the electrical meter: how to inspect for & report service ampacity, service entry defects & hazards. Carson Dunlop Associates' sketch at page top shows where the electrical inspection starts at a residential property. Iirc, the electrical code typically calls for #3 or #4 gauge wire on each phase for 100Amp service. You'd likely need one sensor on each phase and keep in mind that you may end up double counting current on 240v appliances though with correct impact on your bill. According to the NEC, the wire size for 200 amp service is a 3/0 AWG copper wire or 4/0 AWG aluminum wire. You should increase wire size by 20% for every extra 100 feet run to account for voltage drop. For a 200-amp cable size spanning over 200 feet, choose a 500 kcmil copper wire or a 1000 kcmil aluminum wire.

The breaker box, or service panel, operates as a central relay point: It takes power from the street, then feeds that power to the different electrical outlets and hard-wired appliances.Wiring a panel box is an essential skill for any homeowner or aspiring electrician. It involves connecting the electrical service entrance wires to the breakers and circuits in the panel box, ensuring safe and efficient distribution of electricity throughout your home or building. In most jurisdictions, homeowners can install their own electrical service as long as they do the homework, pull the permit, and collaborate with the inspector and the utility company. Changing out an energized, existing service, however, is altogether different and is best left to a qualified, licensed electrician.

Installation of 100 amp electric service or subpanel needs a #4 AWG copper wire or #2 AWG aluminum or copper-clad wire inside a minimum 1.25 inch, schedule 40 or 80 PVC electric conduit for underground service. Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box. The electrical service masts should not be more than 3-f eet vertically above the roof line; most utilities will require bracing or guy wires for additional support of any mast that is taller than 3-feet. Understand the basics of your home's electrical service panel to keep you safe and your home well-lit and energized. The electrical panel connects the external electrical wires to the home's internal electric system.

residential electrical service panels

Electrical service entry wiring, service entry cabling (SEC), & the electrical meter: how to inspect for & report service ampacity, service entry defects & hazards. Carson Dunlop Associates' sketch at page top shows where the electrical inspection starts at a residential property. Iirc, the electrical code typically calls for #3 or #4 gauge wire on each phase for 100Amp service. You'd likely need one sensor on each phase and keep in mind that you may end up double counting current on 240v appliances though with correct impact on your bill. According to the NEC, the wire size for 200 amp service is a 3/0 AWG copper wire or 4/0 AWG aluminum wire. You should increase wire size by 20% for every extra 100 feet run to account for voltage drop. For a 200-amp cable size spanning over 200 feet, choose a 500 kcmil copper wire or a 1000 kcmil aluminum wire. The breaker box, or service panel, operates as a central relay point: It takes power from the street, then feeds that power to the different electrical outlets and hard-wired appliances.

Wiring a panel box is an essential skill for any homeowner or aspiring electrician. It involves connecting the electrical service entrance wires to the breakers and circuits in the panel box, ensuring safe and efficient distribution of electricity throughout your home or building. In most jurisdictions, homeowners can install their own electrical service as long as they do the homework, pull the permit, and collaborate with the inspector and the utility company. Changing out an energized, existing service, however, is altogether different and is best left to a qualified, licensed electrician.

Installation of 100 amp electric service or subpanel needs a #4 AWG copper wire or #2 AWG aluminum or copper-clad wire inside a minimum 1.25 inch, schedule 40 or 80 PVC electric conduit for underground service.

Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box. The electrical service masts should not be more than 3-f eet vertically above the roof line; most utilities will require bracing or guy wires for additional support of any mast that is taller than 3-feet.

residential electrical panel boxes

inside electrical panel box

electrical service panel location

electrical service panel list

With a little practice, it's easy to fill unwanted holes in sheetmetal with a MIG welder. Anyone who has modified a car knows there are times when you need to drill holes in a firewall, or.

electric box at service wire|inside electrical panel box