cnc lathe part off program This comprehensive guide covers everything you need to know about parting off on a CNC lathe, including the tools and techniques you'll need to achieve clean and accurate cuts. Learn how to set up your lathe, choose the . A distribution box (DB box) is an essential component in electrical wiring installation, serving as a central junction from which cable routes diverge to different outlets and switches throughout a premises.

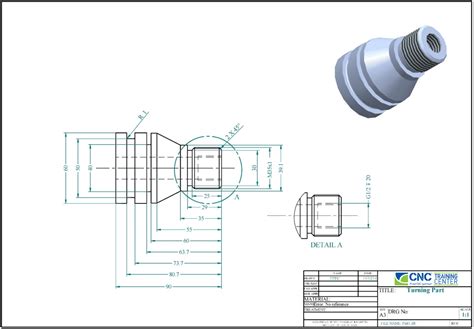

0 · cnc programming examples with drawing

1 · cnc lathe programming tutorial basics

2 · cnc lathe programming for beginners

3 · cnc lathe program examples

4 · cnc lathe instruction manual programming

5 · cnc lathe bearing programming software

6 · cnc lathe bearing programming guide

7 · 7 axis lathe programming software

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

Welcome back to our series on programming a complete part using G-Code on a CNC Lathe! In this episode, Marc from @GCodeTutor leads us through the crucial facing sequence, following the parting off process.In the next part of our programming a bush series, Marc from G-Code Tutor talks us .As we continue to use point-to-point G01 to part off, Marc explains why he rapids the . G75 and Peck Parting Off For Lathes. How and When to Use Peck Parting Off; Make Peck Parting Super-Easy With Conversational CNC; More .

This comprehensive guide covers everything you need to know about parting off on a CNC lathe, including the tools and techniques you'll need to achieve clean and accurate cuts. Learn how to set up your lathe, choose the . In the next part of our programming a bush series, Marc from @GCodeTutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our.

In the next part of our programming a bush series, Marc from G-Code Tutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our machine into a safe state. By . As we continue to use point-to-point G01 to part off, Marc explains why he rapids the X-axis out of the way first before returning to the machine datum. If the tip broke during the .

asap metal fabricators yakima wa

This time he gives us the inside scoop on parting off on your lathe using the tools available on HaasTooling.com.

CNC lathe program which machines a long groove in x-axis using G75 grooving cycle then parts the same component using G75 grooving cycle.Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and .A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis .

Welcome back to our series on programming a complete part using G-Code on a CNC Lathe! In this episode, Marc from @GCodeTutor leads us through the crucial facing sequence, following the parting off process.

G75 and Peck Parting Off For Lathes. How and When to Use Peck Parting Off; Make Peck Parting Super-Easy With Conversational CNC; More Articles on CNC Lathe Programming. Chatter in Machining: Milling & Lathe Vibration This comprehensive guide covers everything you need to know about parting off on a CNC lathe, including the tools and techniques you'll need to achieve clean and accurate cuts. Learn how to set up your lathe, choose the right tooling, and troubleshoot common issues. In the next part of our programming a bush series, Marc from @GCodeTutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our.

In the next part of our programming a bush series, Marc from G-Code Tutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our machine into a safe state. By doing this, it enables us to stop the program mid-sequence and safely start up from the beginning of any other sequence. As we continue to use point-to-point G01 to part off, Marc explains why he rapids the X-axis out of the way first before returning to the machine datum. If the tip broke during the parting off procedure and the part is still attached to the stock bar, the parting blade will break.This time he gives us the inside scoop on parting off on your lathe using the tools available on HaasTooling.com.

CNC lathe program which machines a long groove in x-axis using G75 grooving cycle then parts the same component using G75 grooving cycle.

Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion.

Welcome back to our series on programming a complete part using G-Code on a CNC Lathe! In this episode, Marc from @GCodeTutor leads us through the crucial facing sequence, following the parting off process. G75 and Peck Parting Off For Lathes. How and When to Use Peck Parting Off; Make Peck Parting Super-Easy With Conversational CNC; More Articles on CNC Lathe Programming. Chatter in Machining: Milling & Lathe Vibration

This comprehensive guide covers everything you need to know about parting off on a CNC lathe, including the tools and techniques you'll need to achieve clean and accurate cuts. Learn how to set up your lathe, choose the right tooling, and troubleshoot common issues. In the next part of our programming a bush series, Marc from @GCodeTutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our.

cnc programming examples with drawing

In the next part of our programming a bush series, Marc from G-Code Tutor talks us through writing a full sequence of G-Code to part off. He starts by writing the set-up lines that put our machine into a safe state. By doing this, it enables us to stop the program mid-sequence and safely start up from the beginning of any other sequence. As we continue to use point-to-point G01 to part off, Marc explains why he rapids the X-axis out of the way first before returning to the machine datum. If the tip broke during the parting off procedure and the part is still attached to the stock bar, the parting blade will break.This time he gives us the inside scoop on parting off on your lathe using the tools available on HaasTooling.com.CNC lathe program which machines a long groove in x-axis using G75 grooving cycle then parts the same component using G75 grooving cycle.

assembling junction box with 3-wire plugs

Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.

cnc lathe programming tutorial basics

cnc lathe programming for beginners

When specifying BELL® Weatherproof boxes and covers, consult the requirements of the National Electrical Code®, Article 314.16 (B) and 406.9 (B). Article 314.16 (B) details the NEC® requirements for the maximum number of conductors allowed for a BELL® Weatherproof installation. Article 406.9 (B) provides details on the NEC® requirements for

cnc lathe part off program|cnc lathe program examples