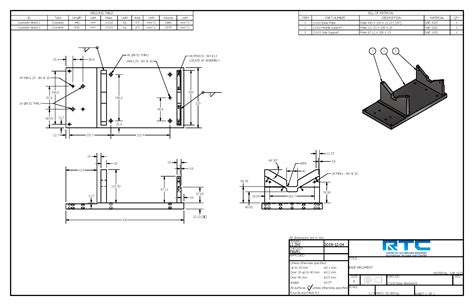

weld sheet metal drawing When there is no side significance this can commonly be applied using a resistance spot welder which is used widely in sheet metal work. A spot weld . Our Main Business: CNC Machining Service, including CNC Turning Parts, CNC Milling Parts,CNC Drilling/Grinding/Stamping Parts Etc.

0 · weldment drawing examples

1 · welding notation in drawing

2 · welding drawings easy

3 · welding blueprint lines and symbols

4 · weld specifications on drawings

5 · stitch welding symbols on drawings

6 · spot welding symbol in drawing

7 · blueprint welding symbols chart

Rally offers unparalleled precision and reliability as a trusted supplier of high quality turned parts. We specialize in making parts that strictly adhere to specified shape, size and material requirements, ensuring optimal fit and function.

weldment drawing examples

Learn welding symbols easily with our in-depth guide, featuring detailed charts, drawings, explanations and real examples.When there is no side significance this can commonly be applied using a resistance spot welder which is used widely in sheet metal work. A spot weld .Mechanical Engineering solution for ConceptDraw DIAGRAM charting and drawing software is full of the pre-made examples of the mechanical drawings and stencil libraries full of the mechanical engineering-related symbols it .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

Drawing Callout for Weld Symbols 2.1.1. General Weld Schematic Note: Symbols shown above are typical for all welded joints of similar construction unless . Base Metal Thickness (T) in Inches Minimum Size of Groove/Bevel Weld . 0.250 in < T ≤ 0.500 in. 3/16 in. 0.500 in < T ≤ 0.750 in. 1/4 in: 0.750 in < T ≤ 1.50 in.

Identification of the weld process is required as part of the weld symbol the relevant weld process code is listed in BS EN ISO 4063. Basic Weld Symbol. The weld symbol always includes 1. An arrow line 2. A reference line 3. A dashed line 4. A symbol. Note: Weld symbols on the full reference line relates to welds on the near side of the plate .Position the two metal pieces in the desired arrangement, taking into consideration the welding joint and the orientation of the pieces. Use the "Weldment" feature in SolidWorks to create a weld bead between the two metal pieces. This can be done by selecting the edges or faces of the metal pieces where the weld bead is required.4. Basics of Welding Symbols 21 5. Supplementary Welding Symbols 27 6. Fillet Weld Symbols 33 7. Groove Welding Symbols 45 8. Plug Weld symbols 60 9. Spot, Seam, Stud Welding Symbols 67 10. Edge Weld Symbols 77 11. Process and Method 83 12. Pipe Symbols 87 13. Pipe Drawings 92 . Interpreting metal fab drawings. Interpreting metal fab drawings

I typically use one drawing per individual sheet metal part, and if it is welded that is treated as one weldment part. The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating .

Edge weld symbols are most commonly associated with sheet metal or “gauge” material. This gauge is a system used in order to call out sheet metal similar to that of electricians and wire. This chart can range from the largest gauge of carbon steel at #7 which is a decimal of .1793” all the way to the smallest which is #28 at a decimal of .presented in Table 1. The top sheet metal is the 6013-T6 aluminum alloy, and the bottom sheet metal is the 2029-T8 aluminum alloy. The top sheet metal is refill friction stir spot welded onto the bottom sheet metal using the robotic RFSSW system in Figure 1. The configuration of the sheet metal panel is depicted in Figure 2. The panel clamping .

Welding Symbols that can be used when drawing sheet metal fabrications. There are occasions when simply saying weld here or corners to be welded doesn’t fully explain what may be important to you for your sheet metal fabrication design. To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. . and deep drawing. Each technique requires different skills and tools to produce quality results. Sheet metal comes in different types such as stainless .equipment, the specific unit in the welding diagram is first manually redrawn and then the corresponding sheet metal parts are cut, which is inefficient. To this end, this paper proposes a U-net-based method for the segmentation and extraction of specific units in welding engineering drawings. This method enables AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code: This specific code addresses the arc and braze welding requirements for nonstructural sheet metal fabrications. It encompasses commonly welded metals available in sheet form and includes requirements and limitations governing procedure, performance qualification, workmanship, and inspection .

Sheet Metal and Welding Quiz. What happens to the thickness of sheet metal as you go from 8 gauge to 22 gauge? Identify 2 methods of showing sheet metal parts on a mechanical drawing. Identify 2 methods of dimensioning features on a sheet metal part. Define bend allowance and identify 3 factors that impact the amount of bend allowance presence. Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process .

welding notation in drawing

Preparation materials for CSWPA sheet metals, welding, surfacing, drawing tools . . surfaces, sheet metal, etc.), look at every feature those tabs let you make, and try to make a model for each of those features that uses it a couple different ways. Flip all the switches, check/uncheck every box, see what makes that feature tick! . Sometimes usage of a backing bar is specified on welding drawings by a supplementary backing bar welding symbol. Fit-up and joint design: Sheet metal welding demands really tight fit-ups. In a situation when a welder . As stated earlier, Weld Symbol is a term used explicitly to designate a specific type of weld.The pertinent types of welds considered under the governing AWS A 2.4 specification for ‘Symbols for welding, brazing and non-destructive examination’ and the basic weld symbols are shown in figure-2. Primary and Supplementary Welding SymbolsHow to model weld’s for sheet metal fabrication. (Details in the comments) Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New. Controversial. Old. Q&A. . Just standard weld callouts are sufficient for a shop drawing Reply reply

Hi, I am completing a sheet metal design that requires welding to fasten the design at its four corners (the shape is basically a rectangular box) Two things I am noticing is that Fusion 360 doesnt seem to have bend rules properly suited to making a design that's weldable, and also you can annotate welds in drawings. Can someone help with work arounds for both .

The design of a welded joint is not an easy job, and often an improperly designed joint can lead to a poorly constructed product.. The word weld is a term that refers to the welding process and the kind of weld joint filler metal, heat-affected zone and material temper, porosity shrinkage, distortion structural integrity, etc. . The majority of all of the above terms and .Detailing and Drawings: DFMXpress: DriveWorksXpress: FloXpress: SLDXML Data Exchange: SOLIDWORKS Explorer: Import and Export: Model Display: Mold Design: Motion Studies: Parts and Features: . To add weld beads to a sheet metal corner: Click Welded Corner (Sheet Metal toolbar) or Insert > Sheet Metal > Welded Corner. Select one of the corner .Sheet metal joinery uses welding metal ____ inches or less in thickness. 3/16 ____ lines may also be applied to a detail drawing to indicate lengths to be welded. Hatching. When specifying the length and spacing of intermittent edge welds, the dimensions are placed to . To draw sheet metal bend lines, first determine the sheet metal bend allowance. The bend line position is determined based on the bend allowance.In the illustration below, the bend allowance is calculated using the formula: inner dimension + inner dimension + compensation factor.. Related reading: Bend Allowance Formula The sheet metal thickness is .

SHEET METAL WELDING GUIDE . Updated figures and drawings of typ-ical welded joint designs. New guidelines for developing welding procedures are provided in the chapter on standards, codes and specifications. Estimating is expanded and provides both a short and long method of estimating welding costs with ex-With sheet metal in particular, using PEM inserts or rivets instead of welding can save signficant time and money if functionality permits. Sheet metal design reviews and drawing preparation. As with any design, mistakes are inevitable. At Five Flute we’re big fans of what we call a continuous design review process.

Interpreting metal fab drawings. 2. Blue Print Review. 3. Joint types and Terminology. 4. Basics of Welding Symbols . When there is no side significance this can commonly be applied using a resistance spot welder which is used widely in sheet metal work. A spot weld is simple a weld applied to the surface of one member that has enough heat .

H. Arnold Wood Turning supplies custom wood turnings, dowels, handles, architectural components & other wood products at wholesale prices. Welcome to H. Arnold Wood Turning, Inc. For over 100 years, we have been the one-stop source for all your made-to-order wooden product requirements.

weld sheet metal drawing|welding blueprint lines and symbols