complex cnc machining service price High-End CNC Machine Prices Explained. When one considers a high-end CNC machine, it is now clear that the majority will be willing to part with quite a large sum of money on the sites as these machines come with excellent features; according to some sources, they . For box mounting I use 2 #8 pan/ washer head screws. All the ones I have seen are Phillips or square drive #2, but there may be straight. Inspectors like the square head #2 because usually only electricians use these so it can help you pass inspection.

0 · round cnc milling cost

1 · round cnc machining cost

2 · custom cnc machining services

3 · cost of cnc machining

4 · cnc machining price list

5 · cnc machining factory

6 · cnc machining company

WEATHERPROOF COVER: Get maximum toughness and protection. Our 2-Gang Weatherproof In-Use Electrical Outlet Cover for home improvement is .

round cnc milling cost

High-End CNC Machine Prices Explained. When one considers a high-end CNC machine, it is now clear that the majority will be willing to part with quite a large sum of money on the sites as these machines come with excellent features; according to some sources, they .

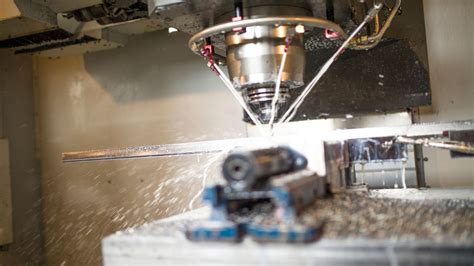

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC . High-End CNC Machine Prices Explained. When one considers a high-end CNC machine, it is now clear that the majority will be willing to part with quite a large sum of money on the sites as these machines come with excellent features; according to some sources, they can range from ,000 to 0,000 at the minimum.On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC machine all types of parts, from simple “as machined” workholdings to complex geometries.

welding clamps for sheet metal

round cnc machining cost

CNC machining prices can vary significantly depending on several factors, including the complexity of the part, material, machine time, and finishing processes.

Managing costs in CNC machining requires a deep understanding of several key factors that directly influence the overall expenses of production. Here are the key strategies for cost reduction: Optimize part manufacturability by simplifying geometry and reducing radii, blind holes or other features to reduce the number of machine setups. CNC machining is a complex process involving various aspects directly impacting the overall cost. Understanding these factors is crucial for businesses looking to optimize their operations and manage expenses effectively. Let’s examine the . Typically, the total cost per hour for 3-axis CNC milling services ranges from to . However, the total cost per hour for 4- or 5-axis CNC machining is between and . Because these multi-axis machines have higher tooling costs and more complex operations, the result is that CNC machining will be more expensive.Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders.

According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained models can retain up to 70% of their original value.

In this blog post, we will delve into the factors that influence the cost of CNC machining and provide you with a comprehensive breakdown of the expenses involved. 1. Complexity of the Design:\ The complexity of the design plays a significant role in . A 3-axis milling machine costs around per hour, while a 4-axis or 5-axis variant can be anywhere between and 0 per hour. The level of finish (rough or smooth) affects the pricing, and the cost of materials will be billed to the client. RELATED: High-End CNC Machine Prices Explained. When one considers a high-end CNC machine, it is now clear that the majority will be willing to part with quite a large sum of money on the sites as these machines come with excellent features; according to some sources, they can range from ,000 to 0,000 at the minimum.

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC machine all types of parts, from simple “as machined” workholdings to complex geometries.CNC machining prices can vary significantly depending on several factors, including the complexity of the part, material, machine time, and finishing processes. Managing costs in CNC machining requires a deep understanding of several key factors that directly influence the overall expenses of production. Here are the key strategies for cost reduction: Optimize part manufacturability by simplifying geometry and reducing radii, blind holes or other features to reduce the number of machine setups.

weldable sheet metal

CNC machining is a complex process involving various aspects directly impacting the overall cost. Understanding these factors is crucial for businesses looking to optimize their operations and manage expenses effectively. Let’s examine the .

Typically, the total cost per hour for 3-axis CNC milling services ranges from to . However, the total cost per hour for 4- or 5-axis CNC machining is between and . Because these multi-axis machines have higher tooling costs and more complex operations, the result is that CNC machining will be more expensive.

Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders.

According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained models can retain up to 70% of their original value.In this blog post, we will delve into the factors that influence the cost of CNC machining and provide you with a comprehensive breakdown of the expenses involved. 1. Complexity of the Design:\ The complexity of the design plays a significant role in .

custom cnc machining services

Used in either indoor or outdoor applications, these enclosures combine a rugged continuous hinge, seamless foam-in-place gasket and stainless steel screw-down clamps for a reliable seal that protects components from corrosive environments.

complex cnc machining service price|cost of cnc machining