battery junction box bjb The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring. On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC machine all types of parts, from simple “as machined” workholdings to complex geometries.

0 · intelligent battery junction box

1 · high voltage battery box

2 · bms battery junction box

3 · bjb relay box

4 · battery pack box

5 · battery junction box diagram

6 · battery junction box architecture

7 · battery junction box

Machitech offers custom CNC Plasma Cutting systems solutions for all businesses and sizes. From turn-key CNC Plasma Tables to custom cutting and drilling solutions, our team of more than 20 engineers and drafters will design the steel processing machine you need.

The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the .The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger. Figure 1a shows the traditional .

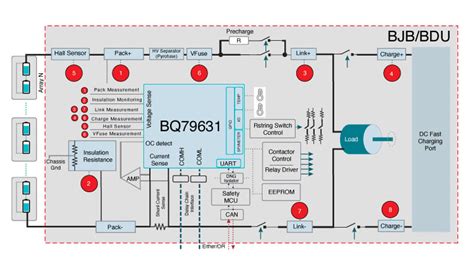

The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger. Figure 1a shows the traditional BMS. Figure 1b shows the intelligent BJB. A dedicated pack monitor inside the box measures all voltages and currents and passes the information to the MCU using simple twisted-pair communication. It helps eliminate wires and cabling harnesses; and improves voltage and current measurements with lower noise.The RDBESS772BJBEVB is a Battery Junction Board, part of RD-BESS1500BUN for HV BESS. It provides TPL interface, current, voltage, temperature, isolation measurements for 1500 V and 500 A systems.

The RD772BJBTPLEVB is a battery junction box (BJB) reference design with electrical transport protocol link (ETPL) communication. It is ideal for rapid prototyping of a high-voltage battery management system (HVBMS) hardware and software.

Intelligent battery management system (BMS) introduction. Voltage (V), current (I) and insulation resistance (R) measurements. VI synchronization in BMSs. Summary. • Main BMS function: monitor cell voltage (VCELL), pack voltage (VPACK) and pack current (IPACK). Traditional BMS. Eliminates numerous connections in BMU and BJB interface.

The battery junction box (BJB) establishes the connection and also the resolution of the connection between the vehicle's high-voltage system and the AC/DC charging components. The BJB is usually located inside the battery, but in some cases it can also be located outside the vehicle, in which case it is simply referred to as the junction box (BJ). Figure 1 shows a typical BMS architecture that includes a battery management unit (BMU), a cell monitoring unit (CMU), and a battery junction box (BJB). The BMU usually contains a microcontroller (MCU) that manages all the functions in the battery pack.3 Traditional vs. intelligent battery junction box (BJB) Discover how silicon innovations are enabling a shift toward a more modern architecture known as the intelligent BJB, and learn about the role of the battery control unit (BCU) as the communication interface. The BMS protects the battery from damage, extends

The RD772BJBCANFDEVB is a battery junction box (BJB) reference design with CAN FD communication. It is meant for rapid prototyping of a high-voltage battery management system (HVBMS) hardware and software.The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.

The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger. Figure 1a shows the traditional BMS.

Figure 1b shows the intelligent BJB. A dedicated pack monitor inside the box measures all voltages and currents and passes the information to the MCU using simple twisted-pair communication. It helps eliminate wires and cabling harnesses; and improves voltage and current measurements with lower noise.The RDBESS772BJBEVB is a Battery Junction Board, part of RD-BESS1500BUN for HV BESS. It provides TPL interface, current, voltage, temperature, isolation measurements for 1500 V and 500 A systems.

The RD772BJBTPLEVB is a battery junction box (BJB) reference design with electrical transport protocol link (ETPL) communication. It is ideal for rapid prototyping of a high-voltage battery management system (HVBMS) hardware and software.Intelligent battery management system (BMS) introduction. Voltage (V), current (I) and insulation resistance (R) measurements. VI synchronization in BMSs. Summary. • Main BMS function: monitor cell voltage (VCELL), pack voltage (VPACK) and pack current (IPACK). Traditional BMS. Eliminates numerous connections in BMU and BJB interface.

The battery junction box (BJB) establishes the connection and also the resolution of the connection between the vehicle's high-voltage system and the AC/DC charging components. The BJB is usually located inside the battery, but in some cases it can also be located outside the vehicle, in which case it is simply referred to as the junction box (BJ). Figure 1 shows a typical BMS architecture that includes a battery management unit (BMU), a cell monitoring unit (CMU), and a battery junction box (BJB). The BMU usually contains a microcontroller (MCU) that manages all the functions in the battery pack.

intelligent battery junction box

3 Traditional vs. intelligent battery junction box (BJB) Discover how silicon innovations are enabling a shift toward a more modern architecture known as the intelligent BJB, and learn about the role of the battery control unit (BCU) as the communication interface. The BMS protects the battery from damage, extends

working principle of cnc lathe machine

wrought metal 16 hanging angle bracket

$298.43

battery junction box bjb|battery junction box diagram