arc welding sheet metal tips Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas . Traffic Rated - Concrete Well with Cast Iron Cover • Standard cover reads “GROUND”. • Access well is H-20 rated, suitable for heavy traffic. • Reinforced concrete box with cast iron ring. • Must be shipped by truck only. * NE suffix indicates a “No Extension” version, shown on the right. Part No. Diameter Length Approx. Each Wt .

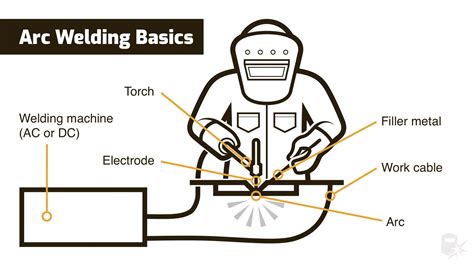

0 · basics of arc welding

1 · basic steps of arc welding

2 · arc welding videos for beginners

3 · arc welding tips for beginners

4 · arc welding techniques and tips

5 · arc welding setup diagram

6 · arc welding procedure step by

7 · arc welding for dummies

These tricks and tips would make MIG welding of thin sheets easy, smooth, and swift. Thus, let’s get into the MIG welding techniques if you don’t want to ruin the entire process and the thin sheet metal. When you MIG weld any metal sheet, you must look at and care for two things. Burning through the sheet itself.

When using Flux Core Arc Welding (FCAW) to weld sheet metal, it is crucial to properly adjust the welding machine settings to ensure a stable and consistent arc, and to . Transform thin metals into sturdy constructions with sheet metal welding. Get expert tips on MIG and TIG techniques – start perfecting your skill now!

This article introduces you to sheet metal welding, including various techniques and surface orientation, and provides expert tips for making high-quality welds. Table of . Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas . Arc welding is a type of welding process that uses an electric current to melt metal wire or rod and fuse it together. Arc welding requires two electrodes: a positive electrode called the consumable electrode or filler . Metal inert gas (MIG) welding is an arc welding method typically used on large parts made of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a welding gun into .

basics of arc welding

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still . To master the art of welding sheet metal using TIG and MIG, you need to follow some tips for successful welding. You can start by choosing the right filler metal, controlling heat input, managing distortion, and ensuring . Gas Metal Arc Welding (GMAW), commonly referred to as MIG welding, is a popular form of welding in which a wire electrode is introduced into a shielding gas to form a weld. It works well for joining many metals, including .

lighting junction box uk

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. When using Flux Core Arc Welding (FCAW) to weld sheet metal, it is crucial to properly adjust the welding machine settings to ensure a stable and consistent arc, and to prevent overheating of the wire or the workpiece. Transform thin metals into sturdy constructions with sheet metal welding. Get expert tips on MIG and TIG techniques – start perfecting your skill now! This article introduces you to sheet metal welding, including various techniques and surface orientation, and provides expert tips for making high-quality welds. Table of Contents. What is Sheet Metal Welding? Different Techniques of Welding Sheet Metal MIG Welding; TIG Welding; Stick Welding; Plasma Arc Welding; Laser Beam Welding; Gas Welding

basic steps of arc welding

Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas tungsten arc welding (GTAW). Arc welding is a type of welding process that uses an electric current to melt metal wire or rod and fuse it together. Arc welding requires two electrodes: a positive electrode called the consumable electrode or filler material and a negative electrode called the base material. Metal inert gas (MIG) welding is an arc welding method typically used on large parts made of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a welding gun into a weld pool to join two pieces together.

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application. To master the art of welding sheet metal using TIG and MIG, you need to follow some tips for successful welding. You can start by choosing the right filler metal, controlling heat input, managing distortion, and ensuring proper weld joint fit-up, to get the best results.

Gas Metal Arc Welding (GMAW), commonly referred to as MIG welding, is a popular form of welding in which a wire electrode is introduced into a shielding gas to form a weld. It works well for joining many metals, including steel, stainless steel, and aluminium. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

When using Flux Core Arc Welding (FCAW) to weld sheet metal, it is crucial to properly adjust the welding machine settings to ensure a stable and consistent arc, and to prevent overheating of the wire or the workpiece.

Transform thin metals into sturdy constructions with sheet metal welding. Get expert tips on MIG and TIG techniques – start perfecting your skill now!

This article introduces you to sheet metal welding, including various techniques and surface orientation, and provides expert tips for making high-quality welds. Table of Contents. What is Sheet Metal Welding? Different Techniques of Welding Sheet Metal MIG Welding; TIG Welding; Stick Welding; Plasma Arc Welding; Laser Beam Welding; Gas Welding

Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas tungsten arc welding (GTAW). Arc welding is a type of welding process that uses an electric current to melt metal wire or rod and fuse it together. Arc welding requires two electrodes: a positive electrode called the consumable electrode or filler material and a negative electrode called the base material. Metal inert gas (MIG) welding is an arc welding method typically used on large parts made of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a welding gun into a weld pool to join two pieces together. Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

lipo safe metal box

To master the art of welding sheet metal using TIG and MIG, you need to follow some tips for successful welding. You can start by choosing the right filler metal, controlling heat input, managing distortion, and ensuring proper weld joint fit-up, to get the best results.

arc welding videos for beginners

lighting canopy for off center junction box

lighting suspension junction box bracket bar

To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or tack welds to manage heat and allow cooling periods between welds to minimize warping.

arc welding sheet metal tips|arc welding tips for beginners