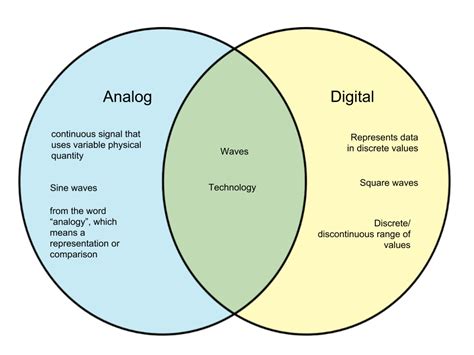

difference between analog and digital junction box Essentially, the difference between an analog and a digital load cell is how the weighing signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content, and data sample rate. A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

0 · What is the Difference Between a Digital & Analog

1 · What is a Junction box, and its applications?

2 · Understanding Load Cell Accuracy (Including Analog

3 · The Difference Between Analog and Digital Load Cells

4 · The Basics of Load Cell Summing and Trimming

5 · Technical Information

6 · PLC Connection : Instrument, Junction Box, Marshalling

7 · Load Cell Junction Box

8 · Digital Load Cell vs. POWERCELL Technology Comparison

I tried to install an outlet on existing junction box as below, but failed because it's too small to put in. I have 3 solutions to think. Remove junction caps and put 2 outgoing lines into backstabs and screws, so it works as junction; Buy conduits and extend another box on the top

A digital load cell outputs numbers to the indicator while an analog load cell outputs voltage. The output of analog load cells depends on applied voltage (the voltage supplied to the load cell by the indicator).

Essentially, the difference between an analog and a digital load cell is how the weighing signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content, and data sample rate.Analogue load cells can be used with our EMULA Smart junction box as part of a hybrid analogue-digital configuration. This offers some advantages over standard analogue load cell systems in certain applications. Both analogue and digital . Essentially, the difference between an analog and a digital load cell is how the signal is processed. Digital load cell systems differ from analog systems in three important . The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about .

This Sasco Africa guide focuses on understanding load cell accuracy, as well as the key differences between analog and digital load cells.

The load cell junction box is critical to the performance of weighing scales that use more than one analog load cell. It affects accuracy due to temperature effects, long-term stability, and corner . Load cell summing and junction boxes properly combine their multiple signals into a useful digital output to display, store, or control complex systems. To ensure the quality of load cell measurement data delivered to .

metal housing for diesel air heater

What is the Difference Between a Digital & Analog

Junction box required Digital Load Cell vs. POWERCELL® Technology Comparison Digital Load Cell Technology Analog signal converted to a strong digital signal Risk of signal disturbance is .A digital load cell outputs numbers to the indicator while an analog load cell outputs voltage. The output of analog load cells depends on applied voltage (the voltage supplied to the load cell by the indicator).Essentially, the difference between an analog and a digital load cell is how the weighing signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content, and data sample rate.Analogue load cells can be used with our EMULA Smart junction box as part of a hybrid analogue-digital configuration. This offers some advantages over standard analogue load cell systems in certain applications. Both analogue and digital weighbridge load cells continue to offer specific advantages.

A PLC connection represents the signal flow starting from the field transmitters, junction box, marshalling cabinet, system cabinet and Human-Machine Interface for the operator graphic display. Essentially, the difference between an analog and a digital load cell is how the signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content and data sample rate.

The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about Junction boxes This Sasco Africa guide focuses on understanding load cell accuracy, as well as the key differences between analog and digital load cells.

The load cell junction box is critical to the performance of weighing scales that use more than one analog load cell. It affects accuracy due to temperature effects, long-term stability, and corner-load adjustment. Load cell summing and junction boxes properly combine their multiple signals into a useful digital output to display, store, or control complex systems. To ensure the quality of load cell measurement data delivered to operators, the individual load cells must be properly trimmed.

Junction box required Digital Load Cell vs. POWERCELL® Technology Comparison Digital Load Cell Technology Analog signal converted to a strong digital signal Risk of signal disturbance is low Simply digitizes the errors inherent in analog signals .A digital load cell outputs numbers to the indicator while an analog load cell outputs voltage. The output of analog load cells depends on applied voltage (the voltage supplied to the load cell by the indicator).Essentially, the difference between an analog and a digital load cell is how the weighing signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content, and data sample rate.

Analogue load cells can be used with our EMULA Smart junction box as part of a hybrid analogue-digital configuration. This offers some advantages over standard analogue load cell systems in certain applications. Both analogue and digital weighbridge load cells continue to offer specific advantages.A PLC connection represents the signal flow starting from the field transmitters, junction box, marshalling cabinet, system cabinet and Human-Machine Interface for the operator graphic display. Essentially, the difference between an analog and a digital load cell is how the signal is processed. Digital load cell systems differ from analog systems in three important ways: Signal strength, signal content and data sample rate. The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about Junction boxes

This Sasco Africa guide focuses on understanding load cell accuracy, as well as the key differences between analog and digital load cells.The load cell junction box is critical to the performance of weighing scales that use more than one analog load cell. It affects accuracy due to temperature effects, long-term stability, and corner-load adjustment. Load cell summing and junction boxes properly combine their multiple signals into a useful digital output to display, store, or control complex systems. To ensure the quality of load cell measurement data delivered to operators, the individual load cells must be properly trimmed.

metal housing for your deadbolt from the outside

What is a Junction box, and its applications?

metal job box for sale

Understanding Load Cell Accuracy (Including Analog

Wiremold Ratchet-Pro Series Floor Box provides single- and dual-service capability in a variety of easy-to-install round floor boxes. These designs allow the flexibility for providing power, A/V or communication services to open-space areas in an aesthetic solution.

difference between analog and digital junction box|The Basics of Load Cell Summing and Trimming