all pull boxes junction boxes and fittings must be what (i) All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each . A CNC press brake machine, equipped with a sophisticated CNC control system, boasts unparalleled efficiency and accuracy. The precision offered by this advanced system significantly reduces the margin of error, ensuring that every bend, fold, and cut is .

0 · utility box junction and pull

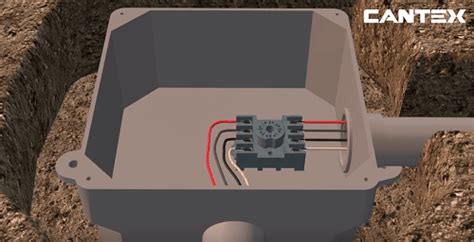

1 · underground electrical pull box installation

2 · standard electrical pull box sizes

3 · nec distance between pull boxes

4 · nec compliant junction boxes

5 · maximum distance between junction boxes

6 · electrical pull box size chart

7 · different types of pull boxes

A breaker box, also known as an electrical panel or fuse box, plays a vital role in your home’s electrical system. It is responsible for distributing electricity to various circuits in your home, ensuring a safe and regulated power supply.

Pull Boxes, Junction Boxes and Fittings: All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, .(i) All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each .

Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over .All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box . All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations .

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be .

Pull Boxes, Junction Boxes and Fittings: All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded.

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.(i) All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy. Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.

All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy. All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used.

Article 370 covers the installation and use of all boxes (and conduit bodies) used as outlet, junction, or pull boxes, depending on their use. [370-1] Boxes containing No. 18 through No. 6 conductors must be sized in accordance with the specifications in 370-16.Pull Boxes, Junction Boxes and Fittings: All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.(i) All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy. Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.

All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

utility box junction and pull

underground electrical pull box installation

All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used.

standard electrical pull box sizes

nec distance between pull boxes

nec compliant junction boxes

What is a Flameproof Junction Box? A flameproof junction box is a special type of electrical box designed to prevent the spread of fire. They are constructed with materials that do not produce toxic fumes or release toxic .

all pull boxes junction boxes and fittings must be what|standard electrical pull box sizes