all pull boxes junction boxes and fittings must be Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over . Here we describe matching 15-Amp receptacles to 15-Amp circuits, 20-Amp receptacles to 20-Amp circuits, two-wire receptacles where no ground is present, GFCI and AFCI electrical receptacles, and the proper electrical box to hold and mount these devices.

0 · utility box junction and pull

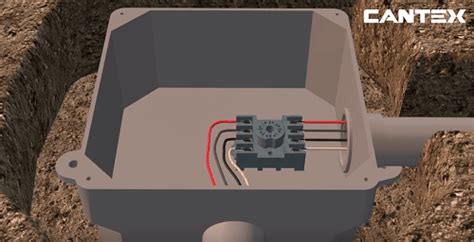

1 · underground electrical pull box installation

2 · standard electrical pull box sizes

3 · nec distance between pull boxes

4 · nec compliant junction boxes

5 · maximum distance between junction boxes

6 · electrical pull box size chart

7 · different types of pull boxes

Mig isn’t like tig where you necessarily want that “dime” look. You should run a consistent, straight stringer bead from start to finish. You wanna push it and keep your wire on the leading edge of .

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, .

Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over .All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be .

All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations .All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

utility box junction and pull

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy. Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used. All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy. Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.

All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

underground electrical pull box installation

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used. All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

sheet metal fabrication equipment used

sheet metal fabrication in chicago heights

Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, .

all pull boxes junction boxes and fittings must be|electrical pull box size chart