flanging process in sheet metal Access To Content. How do I view content on Taylor & Francis Online (TFO)? How . Boost your resume with these 12 essential metal fabricator skills, from welding to precision cutting, to stand out to employers.

0 · shrink flanging process

1 · shrink flange forming process

2 · sheet metal shrink flange

3 · sheet metal forming

4 · sheet metal flanging

5 · metal hole flanging

6 · hole flanging method

7 · flat plate flanging holes

Check out our metal roofing color simulator, interactive color charts, design guides, blogs, and videos. Buy manufacturer direct and save. LOOKING FOR A COLOR CHART INSTEAD? What Is The Best Color For A Metal Roof? How .

shrink flanging process

Hole-flanging is the most widely used/applied form of flanging process. Besides this, shrink flanging process finds its applications in automobile and aircraft parts. The objective of the present study deals with critical review and analysis of sheet metal shrink flanging process.Hole-flanging is the most widely used/applied form of flanging process. .Access To Content. How do I view content on Taylor & Francis Online (TFO)? How .

We would like to show you a description here but the site won’t allow us.

1.1. Principle of stamping-forging processing (SFP) for sheet metal. SFP is a combined metal forming technology of stamping and forging for sheet metal parts. In an SFP, generally, stamping or drawing is used to form the .

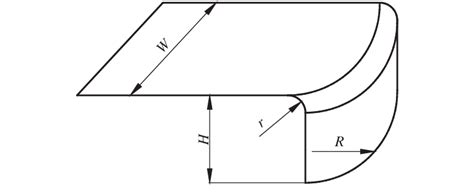

A FEM commercial software programmed called ABAQUS was used to simulate the stretch flanging process of rectangular sheet metal blanks using an explicit dynamic finite element approach. An experimental assembly with dimensions was referenced to Yeh F.H et al (2007) [9] for the creation of a finite element model of the stretch flange process, as . Flanging is sheet metal forming process which has high-end applications from automobile industry to aircraft industry. Straight, stretch, shrink and hole-flanging are the variations of flanging . To demonstrate the processes of model validation for simulation-based models, a sheet metal flanging process is used as an example with the objective that is to predict the final geometry, or springback. This forming process involves large deformation of sheet metals, contact between tooling and blanks, and process uncertainties.

Flanging is sheet metal forming process which has high-end applications from automobile industry to aircraft industry. Straight, stretch, shrink and hole-flanging are the variations of flanging .

Firstly the edge of sheet is bent to 90° degree known as flanging process, followed by bending it further to 135° which is known as pre-hemming process and finally the sheet is bent to further to 180° to form a hem and the process is known as hemming process. . Sheet metal hemming process can be generally classified into two major .AA1060 aluminium alloy and DC01 carbon steel sheet s throughout the metal hole flanging process by using incremental fothe rming technique. The process . Hole flanging operation is typical sheet metal forming process used for a making flanges from pre-cut hole sheets which is provide high stiffness, allow for

Hole flanging is a metal forming process that creates a raised edge or collar around a pre-existing hole in a sheet metal workpiece. This technique utilizes specialized tooling to deform the material surrounding the hole, typically resulting in a cylindrical protrusion perpendicular to the sheet’s surface or at a specified angle. An edge flanging machine is a machine tool used to form a flange on the edge of sheet metal parts. A flange is a raised edge or lip that is created by bending the edge of a sheet metal part. . This is the surface where the sheet metal part is placed during the flanging process. Clamping system: This holds the sheet metal part securely in . Within the manufacturing industry, hole flanging is an essential process for forming local features in sheet metal. To enhance the flanging height, the diameter of the prefabricated hole should be reduced. However, the undersized diameter of the hole may result in a crack during the flanging process. Combining the electropermanent magnet (EPM) technique with . The analysis on the hole-flanging penetration process of sheet metal with semi-spherical punch. Proceedings of the 26th national conference on theoretical and applied mechanics R.O.C., M016 (2002) Google Scholar. McMeeking and .

Flanging is a bonding and forming technology used in sheet-metal forming. By bending over the edge of metal sheets using a flanging machine, the process reinforces the bent edge or creates a connection consisting of multiple components. Blank-holding effect on the hole-flanging process of sheet aluminum alloy. 2011, Journal of Materials Processing Technology . Cold roll forming is a high production but complex metal forming process under the conditions of coupled effects with multi-factor. A new booting finite element method (FEM) model using the updated Lagrangian (UL .

shrink flange forming process

Flanging is sheet metal forming process which has high-end applications from automobile industry to aircraft industry. Straight, stretch, shrink and hole-flanging are the variations of flanging . Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is . In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. . Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. . Firstly the edge of sheet is bent to 90° degree known as flanging process, followed by bending it further to .

Nowadays, lots of flanging parts formed with the sheet metal have been widely used in the automotive industry. The fineblanked-extrusion flanging process can be used to fabricate the sheet metal flanging parts with high surface quality, high dimensional accuracy and production efficiency when compared with the conventional hole flanging process.

Hole-flanging is a common sheet stamping process, which could produce a smooth lip component with improved structural stiffness at the edges [].These finished parts are often used to facilitate additional support for press fitting and pipelines connection [].For the purpose of lightweight and energy consumption, materials with lightweight and excellent . In extruding, the metal is flanged around the perimeter of a prepierced hole. Like during stretch flanging, the metal is susceptible to splitting during forming. Extrusions also are referred to as hole expansions or continuous stretch flanges. Often extrusions are tapped for holding fasteners used in the part assembly process (see Figure 9).The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. In this guide, we will explore the 7 pivotal steps in sheet metal stamping. Each step is a piece of a larger puzzle that, when completed, represents . Hole-flanging is a manufacturing process which is used to form flanges around holes by using sheet metal. A brief and concise review of the contributions made by the previous researchers in the area of hole-flanging process has been presented. Steel sheet material and aluminum alloys are used by researchers for hole flange forming.

Hole-flanging process is one of the sheet metal forming processes that is widely used in automotive, aeronautics and astronautics industry. In conventional hole-flanging, a flat sheet with a pre-cut hole is formed as the punch moves down against a die in order to produce a smooth, round flanged lip with higher strength. . In addition, paraffin base oil was used as the lubricating oil in the previous experiment[5]; with lower viscosity, this lubricating oil creates higher frictional shear stress of ironing after the hole-flanging process Table 1 Material characteristics of bi-metallic sheet metals Sheet metal Thickness/mm Yield stress/MPa Stress strain relation .

Flanging and hemming are two common sheet metal bending processes, which are widely used in automobiles to join inner and outer closure panels for functional requirements, appearance, or safety .Computer-aided process design of selected sheet metal bending processes: flanging and hemming. January 1998. Read More. Author: Haydar Livatyali, Advisers: Gary L. Kinzel, Taylan Altan; Publisher: . This work deals with the virtual simulation of the sheet metal stamping process. The main objective is to predict when and where the cracks can .Die Operation to Flange Sheet Metal. Sheet metal flange operations are usually much simpler than draw operations. Often, part flanges are made in dies that are accomplishing other operations, too. . This was interesting. I have often wondered the exact process of forming car parts. I know that some, like the engine block, are cast in molds .

In this guide, we’ll show you how to glue fabric to metal with all-purpose glue and spray adhesive. They’re both extremely easy to use, and well suited for most DIY and repair projects. All-purpose glues like Loctite Extreme Glue are perfect for projects that involve gluing fabric to metal.

flanging process in sheet metal|flat plate flanging holes