electrical panel box obstruction from open door requirements It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the .

Welcome to UMF Medical's Product Categories. We offer a wide range of high-quality, durable products for healthcare settings, including Power Exam Tables, Power Procedure Chairs, and Pediatric Tables—all designed for patient safety and comfort.

0 · panel door clearance requirements

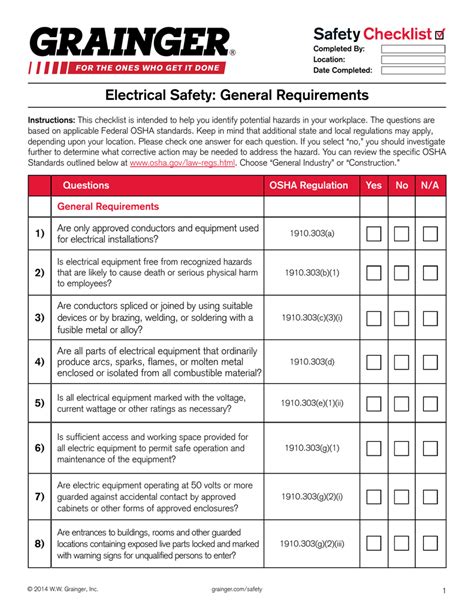

1 · osha outdoor electrical installation requirements

2 · osha electrical panel clearance requirements

3 · electrical panel width requirements

4 · electrical panel opening requirements

5 · electrical equipment door opening requirements

6 · electrical door clearance requirements

7 · building code electrical panel clearance

Below, I'll show you how to do it, too. This project is based on working with drywall — if you're working with tile the process of replacing an outlet is going to be much more involved. Test your non-contact voltage tester on a known live circuit to ensure it works. Stick the tester in the smaller slot of your receptacle.

In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.

The site is secure. The https:// ensures that you are connecting to the official website .The site is secure. The https:// ensures that you are connecting to the official website .

In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is .Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.

It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the .The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the . The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. .

OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed .

And, if the panel does have a door, then it must be openable to 90º (perpendicular to face of box), per NEC 110.26 (A) (2). So a panel without a dead front is a code safety .In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.The 3 foot requirement for electrical panel clearances is the most important one to follow. The panel should be accessible and have enough room in front of it so that an electrician can open the door and work safely. This area needs to remain clear at all times.

In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is situated in a space with limited access:

Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the minimum for safety.The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. All electric equipment installed, modified or repaired after March 1972 must comply with the . OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed Access: Electrical panels must be accessible at . And, if the panel does have a door, then it must be openable to 90º (perpendicular to face of box), per NEC 110.26 (A) (2). So a panel without a dead front is a code safety violation, but a panel without a door may—or may not—be.

degrees of protection provided by enclosures for electrical equipment

In all cases, the working space shall permit at least a 90-degree opening of equipment doors or hinged panels; and 1910.303(g)(1)(i)(C) The work space shall be clear and extend from the grade, floor, or platform to the height required by paragraph (g)(1)(vi) of this section.The 3 foot requirement for electrical panel clearances is the most important one to follow. The panel should be accessible and have enough room in front of it so that an electrician can open the door and work safely. This area needs to remain clear at all times.In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees. When an energized equipment requires servicing/repair but it is situated in a space with limited access:Obstructions: The panelboard’s working space must be kept clear and not used for storage. No obstructions like pipes, cabinets, or doors can block access to the panel.

It also states the working space should permit the equipment doors or hinged panels to open at least 90°, and that working space required by this standard may not be used for storage. This amount of clearance is deemed to be the minimum for safety.The depth shall be as required in Table K-2. The workspace shall be adequate to permit at least a 90-degree opening of doors or hinged panels. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

The workspace also must permit at least a 90-degree opening of all hinged panels and equipment doors. This space cannot be used for permanent fixtures or temporary storage. All electric equipment installed, modified or repaired after March 1972 must comply with the . OSHA has established specific requirements for electrical panel clearance to prevent electrical hazards and promote worker safety, as stated in the 1926.403 standard. Key aspects of this guidelines include: Unobstructed Access: Electrical panels must be accessible at .

panel door clearance requirements

• Cincinatti CL-7 CNC LASER (currently only one of its kind and size in Hawaii) and a full staff of CAD and LASER technicians • Shears capable of cutting metals of various thicknesses • .

electrical panel box obstruction from open door requirements|osha outdoor electrical installation requirements