cnc lathe machine operations In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc. 20 Pack Shelf Brackets 10 Inches White, Heavy Duty Steel Metal L Brackets for Shelves, J Brackets Wall Angel Corner Brace for Wood Board

0 · turning operations on lathe machine

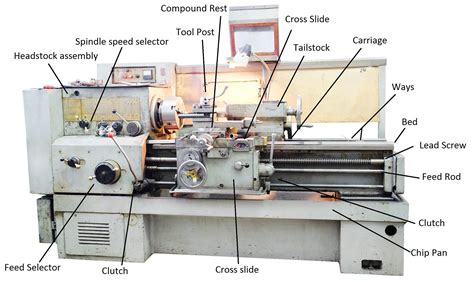

1 · parts of cnc lathe machine

2 · cnc lathe work

3 · cnc lathe process

4 · cnc lathe parts

5 · cnc lathe machine working

6 · centering operation on lathe machine

7 · center lathe operations

Find White curtain rod brackets at Lowe's today. Shop curtain rod brackets and a variety of home decor products online at Lowes.com.

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by . What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it. In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.

Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications. What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency. This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols. With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process. When it comes to figuring out how to operate a CNC lathe, in addition to being taught the basics through formal training, it is important to have the operator’s manual on hand. If you’ve acquired your equipment from a used CNC lathes dealer, you may need to source the operator book from the manufacturer or online.

CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components efficiently with accuracy and consistency. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it. In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.

Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications.

turning operations on lathe machine

parts of cnc lathe machine

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by . What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency.

This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process. When it comes to figuring out how to operate a CNC lathe, in addition to being taught the basics through formal training, it is important to have the operator’s manual on hand. If you’ve acquired your equipment from a used CNC lathes dealer, you may need to source the operator book from the manufacturer or online.

cnc lathe work

what is pallet in cnc machine

With a 1,500-lb load rating, toe-locking brakes, and strong mounting casters, safely stow a wide variety of light and heavy tools to easily access them without breaking your work rhythm. Store up to 100-lbs of tools and attachments with this stout S2000 52-in 10-Drawer Rolling Tool Cabinet.

cnc lathe machine operations|cnc lathe machine working