what is a joggle in sheet metal There are three basic types of bending on a press brake, each is defined by the relationship of the end tool position to the thickness of the material. These three are Air Bending, Bottoming and Coining. The configuration of the tools for these three types of bending are nearly identical. A die with a long rail form tool with a radiused tip that locates the inside profile of the bend is called a punch. Punch. Many metal green roofs tend to feature beige as their exterior paint color since brown makes a house look dark or dreary. To brighten up your beige house with a green roof, add white shutters as shown in this example.

0 · why is metal bendable

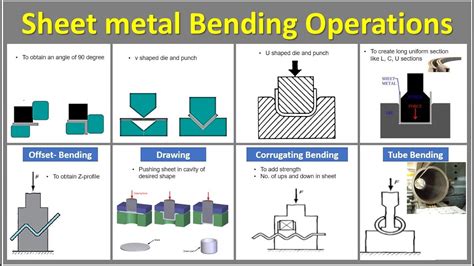

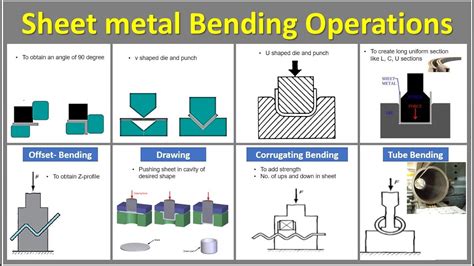

1 · types of sheet metal benders

2 · types of bending sheet metal

3 · shrinking sheet metal by hand

4 · sheet metal joggle examples

5 · lightening holes in sheet metal

6 · forming sheet metal by hand

7 · forming joggles in sheet metal

Nazi concentration camp badges, primarily triangles, were part of the system of identification in German camps. They were used in the concentration camps in the German-occupied countries to identify the reason the prisoners had been placed there. [1] . The triangles were made of fabric and were sewn on jackets and trousers of the prisoners.

Overview of Joggle in Sheet Metal. Joggle is a small offset bend less than 90 degrees. During joggling, one sheet surface goes down due to applied force. The other side slightly goes up from the plane. Both surfaces change from up to .

There are three basic types of bending on a press brake, each is defined by the relationship of the end tool position to the thickness of the material. These three are Air Bending, Bottoming and Coining. The configuration of the tools for these three types of bending are nearly identical. A die with a long rail form tool with a radiused tip that locates the inside profile of the bend is called a punch. Punch. A joggle in sheet metal is a small offset or bend to create an overlapping joint on a flush surface. The offset bending process creates two opposite bends with equal angles in a single action. The joggle bends are in .A joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. Use of the joggle maintains the smooth . Learn about joggling and its function. Follow our mini series for more practical tasks. . For more info visit our website https://code1mx.com and info on our .

Hems and jogs are easy in 3-D CAD, but they require planning, tooling, and setup in the fab shop. This is a CAD setup for an open hem on two edges. Note that closed hems, teardrop, and edge bead are all available from . Joggle forming is when multiple bends are created on a sheet metal creating an angle that is less than 90 degrees. This process mostly involves placing a sheet metal between a punch and a die.

What is Joggle Forming. Joggle forming presses create multiple bends on sheet metal simultaneously. Often, these bends are in opposite directions and less than 90°. A joggle . Joggle Sheet Metal Joggling is a specific metalworking technique used to create bends or offsets in sheet metal. This method is essential for ensuring proper fit and assembly .

Joggling or segmented bending is shaping a sheet metal section by section using stringers and formers. The technique is especially helpful when there is a need to bend an extended workpiece in a periodically repeated pattern.

A joggle is an offset formed to provide for an -overlap of a sheet or angle which is projecting in the same plane. The inside joggle radii should be approximately the same as used for straight bending.Study with Quizlet and memorize flashcards containing terms like what are three requirements for a repair to a piece of sheet metal on an aircraft, which should be stronger the shear strength or bearing strength of a rivet, what kind of stress is one the upper skin of a wing in flight and more. . A joggle is a small offset in a piece of sheet . A reader recently asked for guidance in using 3-D CAD for sheet metal parts. We continue the theme from last month: Skilled designers know how the sheet metal parts get bent. The recommended CAD work flow is to design .

Study with Quizlet and memorize flashcards containing terms like For maximum strength of a formed sheet metal fitting, should the bend be made along or across the grain of the metal?, What determines the minimum bend radius that can be used when forming a sheet metal structural fitting?, What is meant by the neutral axis in a sheet of metal? and more.Joggle cleat is a continuous piece of metal that can be used at the eave, valley, cricket, or transition of a metal roof. The standing seam panel is folded and hooked over the joggle cleat. It's also referred to as an offset cleat. WS-403 Joggle Cleat Dimensions Other aircraft sheet metal fabrication techniques include: Waterjet cutting – you can use the technology to cut sheet metal for aircraft parts; Hot joggle technique is a common technique in the aviation industry for forming multiple sheet metal parts. It allows for better offset near the edges. Laser cutting; CNC milling; Deep drawing; Sheet .We can adjust this press tooling to enable us to vary the height of the joggle (dimension x) from it’s minimum to maximum dimension in the table above. As the 2 bends of the joggled section are pressed into the sheet metal work in 1 operation this will help to keep the costs down for you and it makes it easier for us to maintain the accuracy .

When bending metal, the material on the outside of the curve stretches while the material on the inside of the curve compresses. . (8171) The purpose of a joggle is to? . (8146) A sheet metal repair is to be made using two pieces of 0.0625-inch aluminum riveted together. All rivet holes are drilled for 1/8-inch rivets. The length of the . 7. Joggle Bending. Joggling or segmented bending is shaping a sheet metal section by section using stringers and formers. The technique is especially helpful when there is a need to bend an extended workpiece in a periodically repeated pattern. The working principle of the method is pushing a sheet metal workpiece in an equipment unit or a brake. Overdue Improvements to Inventor Sheet Metal: (#14) Sheet Metal - Enable Aviation Specific Features; John's previous Idea (that I merged with this one - my apologies) was perhaps the closest stand alone request. To correct this I feel authoring a new Idea, containing Sheet Metal Joggle feature in the title, would be the best approach moving . Study with Quizlet and memorize flashcards containing terms like For maximum strength of a formed sheet metal fitting, should the bend be made along or across the grain of the metal?, What determines the minimum bend radius that can be used when forming a sheet metal structural fitting?, What is meant by the neutral axis in a sheet of metal? and more.

Study with Quizlet and memorize flashcards containing terms like A piece of sheet metal is bent to a certain radius. The curvature of the bend is referred to as the A. bend radius. B. bend allowance. C. neutral line., The flat layout or blank length of a piece of metal from which a simple L shaped bracket 3 inches by 1 inch is to be bent depends upon the radius of the desired .The sight line on a sheet metal flat layout to be bent in a cornice or box brake is measured and marked. one radius from the bend tangent line that is placed under the brake. Parts fabricated from alclad 2024-T3 aluminum sheet stock must have all. scratches, kinks, and bends held to a minimum . 165 degrees. the purpose of a joggle is to .

magnesium sheet metal. DD rivets (ice box rivets) are installed. after the annealing process. A rivets are suitable for. non-structural applications. . attempt to joggle the rivet as such- pulling them apart in order to form a joggle. an AN470 rivet is the same as an. NS20470 rivet. An AD rivet is made from. 2117 alloy. About us.A joggle is an offset formed on an angle strip to allow clearance for a sheet or extrusion. What are the dimensions of a properly formed rivet head? The head should be 1-1/2 times the shank diameter in width and 1/2 times the shank diameter in height after buckingWhat calculation must be made when bending sheet metal? . What is a joggle? It is the offset formed on a part to allow clearance for a sheet or another mating part. What is the purpose of lightning holes cut in rib sections? To reduce weight. Describe rivet head marking for A, B, D, AD, and DD rivets. .A joggle is a small offset near the edge of a piece of sheet metal that allows the street to overlap another piece of metal. When drilling stainless steel should the drill be turned fast or slow? the drill should be turned slowly.

The offset process in sheet metal is bending a sheet metal workpiece in an equipment unit or offset bender. Bend the metal by 20° to 30° using the formers. Release the part, turn it over, and joggle sheet metal to bend it again. Repeat till the correct height of the section or the joggle in sheet metal is achieved.

why is metal bendable

what is the purpose of a joggle? allow clearance for an overlying sheet or extrusion. . A sheet metal repair is to be made using two pieces of 0.0625 inch aluminum riveted together. All rivet holes are drilled for 1/8-inch rivets. The length of the rivets to be used will be. I have attached a pdf of a part I'm working on in Inventor. I am needing the joggled area to be vertical, as it's shown on the pdf. I tried using the flange, but it follows the bend line. I appreciate any suggestions, etc. you have.

What is K factor sheet metal? In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend compresses while the outer portion expands (see Figure 1). Why is a joggle joint used?The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out. Take this example of a joggle here: A joggle, or a small offset near the edge of a piece of metal, is sometimes needed when creating sheet metal. It allows two sheet metal parts to overlap and remain flush with each other which can also prevent sliding. To design this, the approach I take is by first creating a skeleton of the edge:

In the following example, you will create a joggle defined on a surfacic flange, but this scenario is also valid for a joggle created on a web. Open the Joggle1.CATPart document. Click Joggle in the Aerospace Sheet Metal toolbar. The Joggle Definition dialog box is displayed.

Study with Quizlet and memorize flashcards containing terms like For maximum strength of a formed sheet metal fitting, should the bend be made along or across the grain of the metal?, What determines the minimum bend radius that can be used when forming a sheet metal structural fitting?, What is meant by the neutral axis in a sheet of metal? and more.Hand-Forming Piece of Sheet Metal with Concave Curve, forming is Started in Center of Curve, or at Edges? 1.Start at Edges: 2.Work Toward Center. What is Joggle in Piece of Sheet Metal? 1.Joggle - Small Offset near edge of Piece of Sheet Metal. 2.Allows Sheet to overlap another piece of metal. About us. About Quizlet; How Quizlet works;

metal fabrication school phoenix

Fortunately, we’ve faced this dilemma numerous times and can conclude that white, oak, gray, navy, dark brown, and black are the best cabinet colors for stainless steel appliances. These options perfectly complement the sleek and modern look of stainless steel, while also creating a striking contrast for a balanced and inviting visual.

what is a joggle in sheet metal|types of bending sheet metal