cnc machine shop safety doc CNC Machine SOPs outline a safe operating procedure for CNC machine use. The SOPs can also be used as a training and induction document . The primary goal is to protect workers from injury or illness by outlining a safe . Insulation Materials: Inside the box, various insulating materials protect wires and connections from moisture and contaminants. Insulation also helps keep the box cool, which is crucial for high-load environments where components might overheat.

0 · safety glass for cnc machines

1 · osha safety for cnc machining

2 · milling machine safety precautions pdf

3 · milling machine hazards and risks

4 · cnc milling machine safety precautions

5 · cnc machine safety pdf

6 · cnc machine safety checklist

7 · cnc machine safe operating procedure

Box steel beams offer a balance between strength and weight. The hollow section reduces the overall weight of the beam while maintaining structural integrity. This makes box beams suitable for applications where weight reduction is important, such as aerospace or automotive engineering. Types of Steel Beams Based on Support

CNC Machine SOPs outline a safe operating procedure for CNC machine use. The SOPs can also be used as a training and induction document . The primary goal is to protect workers from injury or illness by outlining a safe .

box vents for metal roofs

1. Wear appropriate personal protective equipment (PPE) including safety glasses, hearing protection, and closed-toe shoes. 2. Power on the CNC machine and initialize the control .Complete Machine Shop Safety Checklist (Appendix A) when appropriate or required by your supervisor or EHS. Ensuring that each machine operator receives proper training. Ensuring .In case of malfunction: If the tool does not perform as anticipated, or makes an unfamiliar sound, or creates any safety concerns: IMMEDIATELY notify a Maker Ninja and ask them to Lockout .

safety glass for cnc machines

Using machine shop equipment and tools may be hazardous. EH&S teaches you about personal protective equipment, machine guarding, and recommended safety policies. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving .

Machine safety continues to rank in OSHA’s Top 10 violations for manufacturing. Taking a proactive step to evaluate your current machinery, whether legacy or new, will begin the . These programs can incorporate a combination of hands-on training, web-based instruction, and real-world examples to provide a comprehensive understanding of CNC machine safety. By receiving proper . Here are five essential machine shop safety tips when operating CNC equipment. 1. Use the Proper PPE. Personal protective equipment is one of the foundations of establishing a proactive safety program for any machine shop. CNC Machine SOPs outline a safe operating procedure for CNC machine use. The SOPs can also be used as a training and induction document . The primary goal is to protect workers from injury or illness by outlining a safe system of .

osha safety for cnc machining

milling machine safety precautions pdf

1. Wear appropriate personal protective equipment (PPE) including safety glasses, hearing protection, and closed-toe shoes. 2. Power on the CNC machine and initialize the control system according to manufacturer's instructions.

Complete Machine Shop Safety Checklist (Appendix A) when appropriate or required by your supervisor or EHS. Ensuring that each machine operator receives proper training. Ensuring that all machines are properly guarded. Ensuring that inspections of all machine tools and associated equipment are conducted.

In case of malfunction: If the tool does not perform as anticipated, or makes an unfamiliar sound, or creates any safety concerns: IMMEDIATELY notify a Maker Ninja and ask them to Lockout and Tag out the tool until a follow‐up inspection can be completed.

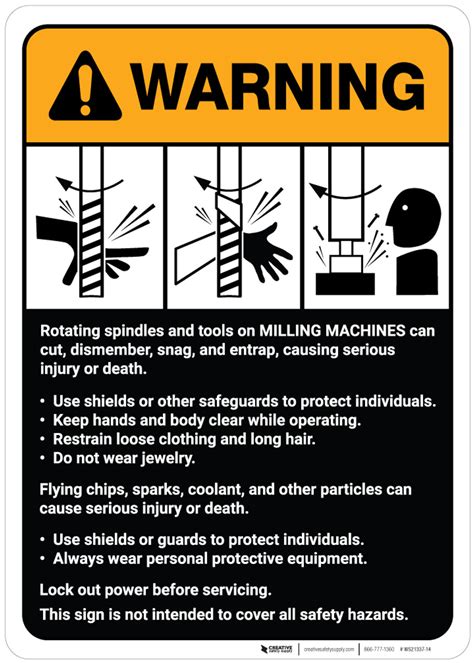

CNC machining is dangerous, even for the most experienced metalworking professionals. That’s why safety managers and industrial hygienists should fully understand the nuances of CNC machine operations and the appropriate safety precautions to .Using machine shop equipment and tools may be hazardous. EH&S teaches you about personal protective equipment, machine guarding, and recommended safety policies. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.Machine safety continues to rank in OSHA’s Top 10 violations for manufacturing. Taking a proactive step to evaluate your current machinery, whether legacy or new, will begin the process of lowering your risk and hazard levels. Polytron’s compli-mentary Machine Safety Checklist is .

These programs can incorporate a combination of hands-on training, web-based instruction, and real-world examples to provide a comprehensive understanding of CNC machine safety. By receiving proper training, CNC machinists can significantly reduce the risk of accidents and injuries in the workplace. Here are five essential machine shop safety tips when operating CNC equipment. 1. Use the Proper PPE. Personal protective equipment is one of the foundations of establishing a proactive safety program for any machine shop.

CNC Machine SOPs outline a safe operating procedure for CNC machine use. The SOPs can also be used as a training and induction document . The primary goal is to protect workers from injury or illness by outlining a safe system of .1. Wear appropriate personal protective equipment (PPE) including safety glasses, hearing protection, and closed-toe shoes. 2. Power on the CNC machine and initialize the control system according to manufacturer's instructions.

Complete Machine Shop Safety Checklist (Appendix A) when appropriate or required by your supervisor or EHS. Ensuring that each machine operator receives proper training. Ensuring that all machines are properly guarded. Ensuring that inspections of all machine tools and associated equipment are conducted.In case of malfunction: If the tool does not perform as anticipated, or makes an unfamiliar sound, or creates any safety concerns: IMMEDIATELY notify a Maker Ninja and ask them to Lockout and Tag out the tool until a follow‐up inspection can be completed. CNC machining is dangerous, even for the most experienced metalworking professionals. That’s why safety managers and industrial hygienists should fully understand the nuances of CNC machine operations and the appropriate safety precautions to .

Using machine shop equipment and tools may be hazardous. EH&S teaches you about personal protective equipment, machine guarding, and recommended safety policies.

milling machine hazards and risks

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.Machine safety continues to rank in OSHA’s Top 10 violations for manufacturing. Taking a proactive step to evaluate your current machinery, whether legacy or new, will begin the process of lowering your risk and hazard levels. Polytron’s compli-mentary Machine Safety Checklist is . These programs can incorporate a combination of hands-on training, web-based instruction, and real-world examples to provide a comprehensive understanding of CNC machine safety. By receiving proper training, CNC machinists can significantly reduce the risk of accidents and injuries in the workplace.

cnc milling machine safety precautions

$86.49

cnc machine shop safety doc|cnc machine safety checklist