sheet metal bending Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that . See more Durham MFG 36 in. x 18 in. x 72 in. 14-Gauge Steel Shelf Cabinet, 4 Shelves, 1,250 lb. Capacity

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Behind that bookshelf is the backside to a fire place. In that space is located a junction box with some wires spliced together. Is this legal? What if there would be a sign or decal on the bookshelf stating that a junction box was located inside?

Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that . See moreAir Bending Air bending is a versatile and widely adopted technique in sheet metal fabrication. The process involves positioning the workpiece on a die with a V-shaped opening, . See more

ISO Standards Sheet metal bending operations must adhere to specific international standards to ensure quality, safety, and consistency. The International Organization for Standardization (ISO) develops and maintains these regulations. For sheet metal . See more

Press Brake Press brakes are versatile sheet metal bending machines that offer high precision and repeatability in producing complex shapes. They utilize a punch and die . See moreManufacturers typically consider using mold bending as a processing method for structural parts that have an annual capacity of more . See moreThis Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .

Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision .

The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part .

Dalsin Industries provides advanced sheet metal bending and forming services for major OEMs across the United States. Our suite of automated Salvagnini panel benders represents the peak of precision . Most frequently, expensive sheet metal bending tools, called brakes, are used to bend sheet metal, but you can also complete this task without one. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . Forces needed to bend sheet metal . Bending . Stress distribution through the thickness of the part s s y Y Y -Y Y Elastic Elastic-plastic Fully Plastic Moment, M = Y (b h/2) h/2 = Ybh2/4 Welcome to RapidDirect's YouTube channel! In this video, we'll dive deep into the world of sheet metal bending, covering everything from the basics to essent. Hello everyone! You are watching video "Make A Simple Sheet Metal Bending Tool- DIY Projects"Learn how to create a simple sheet metal bending tool with this.Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Available on sheet metal and plastic. Hole Operations. Hardware, Tapping, Countersinking. Dimple Forming +1-2 days. Finishing Options. Anodizing, Plating, Powder Coating, Tumbling.

types of bending sheet metal

Another important consideration when designing sheet metal parts is bend orientation. Bends originating from the same plane should be oriented in the same direction to avoid the need of reorienting the part. This will save both money and time. Keeping a consistent bend radius across all bends will also make designs more cost-effective because .

sheet metal bending standards

Ironton Portable Sheet Metal Bending Brake, 30in. Wide. Item # 101452. .99 . Shipping: Available now See Shipping Options. Store Pickup: Check Store Stock. Add to Cart. Activating this checkbox will add this item to the product comparison tool. Compare Save to List. Shop Fox 3-in-1 Combination Sheet Metal Machine, 12in., Model# M1052.Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a . K-factor is a value representing the location of the neutral axis within the sheet metal during the bending process. The neutral axis experiences neither compression nor elongation while bending the sheet metal. With a range between 0 and 0.5, the K-factor varies according to the material and the bending process. A Rule of Thumb in Metal Bending. There’s a rule of thumb to determine a steel’s minimum bend radius, and this generally works for aluminum too: Divide 50 by the material’s tensile reduction percentage as specified by your supplier. This value will vary by grade.

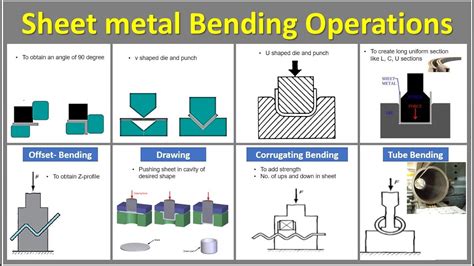

The Sheet Metal Bending process involves the application of external force using a punch and a die at the specified length of the workpiece. This external force results in the plastic deformation of the workpiece. The type of bend and bend length depends on punch and die design.

Sheet metal fabrication tolerances are often slightly larger compared to CNC machining tolerances, as bends in the material can cause the material to stretch. It’s important to note that the more processes a part undergoes, for instance if .KAKA INDUSTRIAL W-1818, 18-Inch Mini Sheet Metal Bending Brake, 0-90 Degrees Adjustable Steel Bender, Portable Bender Bending Bend 16 Gauge Aluminum & Bend 20-Gauge Steel. 3.5 out of 5 stars. 209. .99 $ 58. 99. FREE delivery Sun, Oct 27 . Or fastest delivery Wed, Oct 23 . Small Business.

VEVOR Box and Pan Brake, 48-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Mini Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity Power Handle, for Metal Bending. 3.7 out of 5 stars. 25. 5.99 $ 165. 99. FREE delivery Thu, Nov 14 . .

Sheet metal bend allowance is a critical element of sheet metal bending that compensates for material stretch and spring back during bending. The bend allowance involves adding a calculated dimensional compensation to the flat length of a sheet metal component to ensure that the final part is bent to the specified dimensions. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your .OSH Cut offers on-demand metal bending services in steel, stainless, aluminum, and copper, in thicknesses up to 1/4". Upload your flat pattern with bend lines, or your 3D sheet metal model, to get instant pricing and manufacturability feedback.

Sheet metal bending, also referred to as sheet metal forming, is the process of applying force to a piece of sheet metal in order to change its shape. The bending process takes place using an electric, pneumatic or hydraulic press. The two most common shapes are U and V, although the metal can also be formed into corrugations, curls, flanges or . Press-bending is a key step in metal sheet manufacture. However, DIY approaches are often used and those highly limit the potential of machines and operators. In this guide, press-bending is discussed in all its aspects with an extremely practical approach. The work experiences of the author, as well as his experience as a teacher at the .

extra tall electrical box

Not everything requires a brake; there are lots of other ways to bend sheet metal, especially if it’s a smaller piece. One way that I often work with sheet metal for automotive panels is to sandwich 2×4’s in a vise with the workpiece in the middle, then work the metal with a rubber mallet. The nice thing with this is that you can use .

extra shallow junction box

https://sendcutsend.com/Send Cut Send - Online Laser Cutting, Waterjet Cutting and CNC Router ServiceIn this video: The first video in a new series on bendin.Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.

In this video i have made a sheet metal bending tools. This homemade tool can be use for small fabrication projects,This sheet metal bender only for thin met.The sheet metal bending brake is a versatile tool used in various applications across different industries and settings, including metalworking industries, fabrication shops, maintenance facilities, educational settings, and hobbyist workshops. Specifications. Model : W-1818 : Capacity (Width) 18" Capacity (Thickness)

sheet metal bending near me

$14.99

sheet metal bending|types of bending sheet metal