learn cnc machine operation Embarking on the journey to become a CNC machine operator requires a blend of mechanical insight, software proficiency, and continuous learning. Our exploration has underscored the essential role these operators . With the variety of different electrical boxes available at home centers, how do you know what to buy? Don’t worry, it’s not that complicated. We’ll whittle it down to about a dozen boxes to cover almost every situation.

0 · free online cnc training

1 · cnc training courses near me

2 · cnc router training near me

3 · cnc programming training online free

4 · cnc machine training online

5 · cnc machine learning course

6 · cnc for beginners

7 · cnc courses for beginners

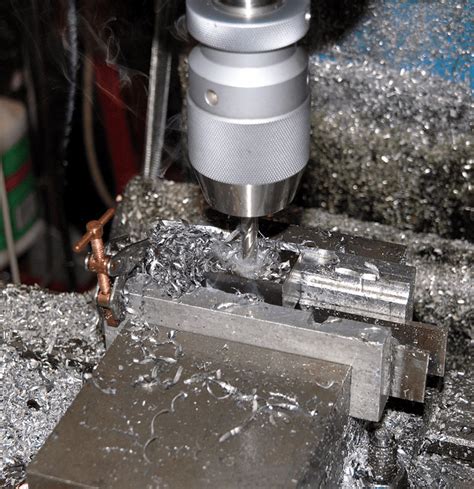

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

Learning CNC machining begins with understanding its fundamental principles and tools. Our guide provides a streamlined overview of CNC courses for beginners, detailing essential topics .Step 1: Choose Your Workspace. Find a suitable location for your CNC machine. Ensure you have enough space to move around comfortably and access power outlets. Consider .

CNC machinists must possess a deep understanding of technical drawings and specifications, alongside proficiency in the operation and programming of key CNC machine tools like lathes, . Embarking on the journey to become a CNC machine operator requires a blend of mechanical insight, software proficiency, and continuous learning. Our exploration has underscored the essential role these operators . Operator: Load raw materials into machines, calibrate equipment, adjust machine operating speeds during a run, and start and stop machines. Setup operator or machinist: Enter the program into the machine, test and .This online CNC Machinist course will provide you with the knowledge and skills you need to prove competency and begin your career quickly. The course provides an intensive overview of the skills necessary to perform CNC .

1. Power control area. 1. System on: turn on the system power. 2. System off: turn off the system power. 3. Program protection switch: turn on and off the program input function. 4. Emergency stop knob: In case of danger or . This process, known as post-processing, ensures the g codes are compatible with the machine’s controller. Learning CNC Programming. CNC programming is the core of CNC machining. It involves writing the instructions that guide the CNC machine to perform specific tasks. . Operating a CNC machine for the first time can be both exciting and . CNC manufacturing is a process that employs computer numerical control (CNC) machines to govern the movements of various industrial tools and machinery, encompassing equipment ranging from grinders and lathes to mills and CNC routers. However, the reliance on manual CNC programming has become a bottleneck, and the requirement for expert .

CNC programming is a crucial skill for operating a CNC machine. Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and troubleshoot common programming errors. What is CNC programming: CNC programming is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece.; How to learn CNC programming: The best way to learn CNC programming is to find a CNC shop that is hiring and start as a machine tool operator.You can also watch online tutorials and use .I'm probably 7 grand in total. a year and a half later, I've learned more doing it this way, troubleshooting and finally getting the machine running, and learning how to edit and write g code, and spot errors in it. I've learned more doing this than I could have in a class, and hey. I've got a 5' cnc machine in my garage in the end.

free online cnc training

Learn how to use a CNC machine to cut metal and wood with our guide. The process involves fun, creativity, and intelligence. . A CNC lathe, or turning machine, allows machine operations such as turning and drilling to be carried out just like with a conventional lathe. It is used to produce cylindrical parts such as slots and threads. CNC machining operations play a crucial role in the production of various parts and are commonly recognized as the driving force behind modern manufacturing processes. Industries such as automotive.

This course will cover the overall operation of a CNC (Computer Numeric Controller) machine. Topics include safety, measurement tools, processes, production, setup, loading tools, offsets, developing and loading a program, and inspecting a part. Training is taught in a blended format of 180 hours of classroom and lab, with an additional online learning component. Additionally, .

Being an operator isn't all too bad if your workplace is alright. My current place allows me to plop in earbuds when doing operator duties (I'm the only cnc guy so I do programming, setup, and operation) while at another I wasn't even allowed to use my phone to double check dimensions.

Learning basic CNC programming is fairly easy. It involves learning how the CNC machine will react to a series of codes. Most of the codes are easy to remember with a little practice (F for feedrate, S for spindle speed) and for any of the harder to remember codes, cheat sheet type references are usually not too far away. Learning advanced CNC .

Learning how to be a CNC machine operator may be challenging, as with any new skill. It requires a solid understanding of the concepts taught within these courses, including machine operations, programming concepts and precision measurement techniques. Ongoing learning, staying current with technological advancements and gaining practical .The older machines are easier. Ask them to teach you on the machines where you have to manually adjust tool offset, and have to use an edge finder first. Because the probe and ats and programmable coolant nozzles and indexers and 4th axis shit is all superfluous knowledge when all you need to learn is set g54, g55Inquire online for CNC machine operator. CNC Machine Training Courses in Philippines. Inquire online for CNC machine operator. Add your courses. Wishlist. Login Register. Toggle navigation. . Learn CNC milling machine programming Course Line . 95% Off for Laimoon Users! get this deal. Duration: Upto 1 Week. 95% Off for Laimoon Users! get this .

Inquire online for CNC machine operator. CNC Machine Training Courses in Kuala Lumpur, Malaysia. Inquire online for CNC machine operator. Add your courses. Wishlist. Login Register. Toggle navigation . Learn CNC milling machine programming Course Line . 95% Off for Laimoon Users! get this deal. Duration: Upto 1 Week. 95% Off for Laimoon Users . G-Code is the language that directs CNC machines in their operations. It is a set of instructions derived from a CAD model that guides the machine on how to move, cut, and shape the material. The role of G-Code is pivotal as it translates the designer’s intent into precise movements and actions of the CNC machine. Key Components of CNC Systems These tips can help you excel in your career and become a highly skilled professional in the field of CNC machine operation. Continuous Learning: Continuous learning is crucial for staying updated with industry advancements and improving your skills as a CNC machine operator. Keep yourself informed about the latest technologies, techniques, and .

Machinists, or machine tool operators, produce parts to precise specifications, generally from setup to operation. In this program, acquire skills for the safe operation of engine lathes, vertical milling machines and surface grinders. Learn to operate computer numerical control (CNC) machines, interpret engineering drawings and use applied mathematics. To Sum Up: Learn CNC Machining. Learning CNC machining from scratch requires you to figure out the fundamental principles and operations of CNC equipment. Beginners wondering how to learn CNC machining should start with the basics of the software and hardware aspects, from G-code programming to the intricacies of tool changers and drive systems.Learn in-demand skills: how to setup and operate manufacturing machines for local employers with high-tech environments. The certificate prepares you with the basic knowledge needed to work as a Computerized Numerical Control (CNC) machine operator, manual machinist, or CNC machinist. Skills include: introduction to basic manual mills and lathes

Explore CNC (Computer Numerical Control) for automated machining. Learn to program and operate CNC machines for manufacturing precision parts. . Leadership and Management, Network Security, Cryptography, Cyberattacks, Operations Management. 4.8. Rating, 4.8 out of .The NIMS CNC Operator program prepares students for entry-level CNC Operator/Machinist roles. Students learn key foundational principles and practices of CNC (Computerized Numerical Control) machine operation, giving them the skills and knowledge needed to successfully work in manufacturing environments. The course covers how to safely and .I was at that particular shop, as an external grinder on manual machines, left the industry for four years and just started 6 months ago at a place that literally has only cnc machines and yes, it can get overwhelming at times, but it is totally worth the effort to learn something new.

If you’d like to learn more about the Machine Tool Operation program, we’d love to talk with you. . Perform programming, set-up and operation of CNC Machine Tools ; Graduate Summary. Graduate Report Summary Overview; Count Percents 2021 2022 2023; Number of Program Graduates: 6: 7: 5: Number of Surveys Sent: 6: 7: 4:Learn more about CNC machine operating and much more. Demand for CNC machine operators is high with manufacturing businesses. It covers basic milling processes; work-holding methods; cutter identification, selection, and use; speeds and feeds; adapters; and tool holders and application. Includes operation of vertical and horizontal manual .

cnc training courses near me

sheet metal tongs

sheet metal supply tulsa

sheet metal tig welding

cnc router training near me

Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire.

learn cnc machine operation|cnc machine learning course