sheet metal relief Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance . CNC machining is a subtractive manufacturing process in which a computer program guides different tools to create a product. The tools include drills, lathes, and mills that cut away at a workpiece to achieve desired specifications.

0 · sheet metal pattern layout methods

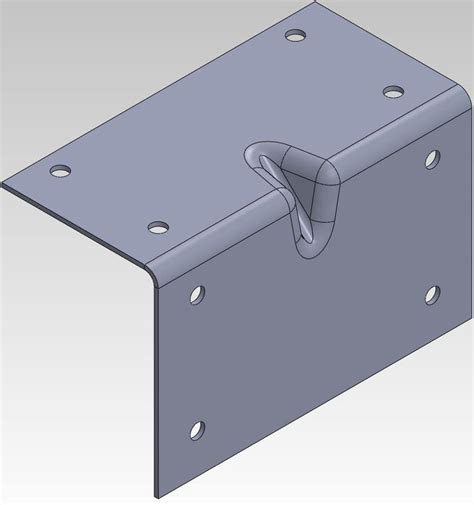

1 · sheet metal gusset design guidelines

2 · sheet metal dimensioning standards

3 · sheet metal dimensioning guidelines

4 · sheet metal corner relief chart

5 · sheet metal bending design guidelines

6 · hole to distance sheet metal

7 · design consideration for sheet metal

Definition of a Septic D-Box: a septic distribution box is a container used to receive septic system effluent from a septic tank and to re-distribute the effluent into a network of attached drain-field or soakaway bed absorption trenches & pipes. The D-box works by gravity, flowing effluent into the drainfield (or leachfield) piping network.

Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance . The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend . A bend relief is nothing more than two small incisions cut into a piece of sheet metal to free the metal between the two. It separates the material you want to be able to fold from the rest of the part. You only need it when . In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors.

Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .

Bend Relief in Sheet Metal Bend Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet . SHEET METAL Training with TOBY: www.TooTallToby.com/training More SOLIDWORKS SHEET METAL videos: https://youtube.com/playlist?list=PLzMIhOgu1Y5deswXMjjl9J.Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and .

Bend Relief. When producing a part with adjoining bends, special cuts must be made into the part to prevent material near the bend from tearing during the bending process. See below an example of an un-manufacturable bend with .

Corner reliefs Corner. reliefs are created automatically when you create a sheet metal design or convert a design to sheet metal.. The corner relief type is determined by the Corner Relief option tool in the Modify group on the Sheet Metal tab. The default type is square, but you can change it to another type.Relief Ratio. The distance d represents the width of the Rectangular or Obround relief cut and the depth by which the side of the Rectangular or Obround relief cut extends past the bend region. The distance d is determined by the following .Relief takes into account any material stretching necessary for unbending the sheet metal model into an accurate flat model for manufacture. You can define relief settings during feature creation, or you can predefine them in the Relief . Tagged: sheet metal, bend relief. Stay Connected! Stay tuned for more updates! Get Updates. I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates. Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States . 877-479-3680 [email protected] Services. Injection Molding. CNC .

Bend Relief. Synchronous sheet metal is pretty cool, even cooler than just normal synchronous modeling, if you’ll excuse that word. For example, if you make a partial flange as above using all the defaults, the software makes relief cuts at the end of the bends, as shown to the right. If you move the flange to the inside of the part, the . If so, it is good practice to create a sheet metal style and not just uncheck use thickness from rule and alter the thickness. Instead use the pencil icon and create sheet metal default for your company thickness. That way you have a dedicated style for each thickness of material and can control relief shapes and bend rads per thickness. 1. No Bend Relief . In sheet metal design, bend relief refers to a small cut or notch made at the intersection of two bend lines. Its purpose is to prevent material deformation, tearing, and other issues during the bending process. When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

Sheet Metal Relief Cut Need to lay a flat pattern of a sheet metal part with a flange with a cut because it is not full length of the original face. Poor Wording. It obviously won't accept it because I am not doing it right. Please take a look at the picture, I'm hopeful someone who works with sheet metal commonly will enjoy the kudos and .

sheet metal pattern layout methods

sheet metal gusset design guidelines

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

Decoding the Essence of Sheet Metal Bend Relief. Sheet metal bend relief isn’t just a design technique; it’s a sophisticated strategy that mitigates the challenges introduced by bending. By incorporating small cuts, openings, or indentations near the bend region, stress concentration is significantly reduced.

Adding a Corner Relief. You can add a corner relief to a single sheet metal body. Corner Relief PropertyManager. Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state.

Bend relief is a term used in sheet metal design to describe a small cut or notch made at the intersection of two bend lines. This helps prevent material deformation, tearing, and other issues during the bending process.This crucial element allows the sheet metal to bend more easily, creating a smoother transition between bends and flat surfaces.

Click Insert > Sheet Metal > Corner Relief. Corner Type. 2 Bend Corner. Creates a corner relief where two bends meet. 3 Bend Corner. Creates a corner relief where three bends meet at one common point. The corner relief is applied at the common intersection point of the bend lines. The model must have three bends where the bend lines meet . The SheetMetal AddCornerRelief command adds a corner relief. A relief is usually created at corners where two bends meet, but the command can also create a relief at an open corner. . The k factor defines where within . Re: Corner relief in sheet metal workspace Post by josenetocruz » Wed Jan 17, 2024 11:50 pm papyblaise wrote: ↑ Wed Jan 17, 2024 2:24 pm what is the point of doing “corner relief”, is there a secret purpose Sheet Metal Relief or Sculpture "Raising" is a technical term applied to making bowls, helmets and various hollow vessles by hammering. The material is actualy made thicker at the edge shrinking the perimeter and making a bowl .

Sheet metal - edge flange/corner relief problem . CAD Hi, once again, I am having hard time with sheet metal - edge flange feature. I need to have these flanges on all these three edges (marked in red) but there is problem with two bottom ones. They intersect each other in flatten state. My idea was to edit each flange and make a 45° cut.Corner reliefs Corner reliefs are created automatically when you create a sheet metal design or convert a design to sheet metal.. The corner relief type is determined by the Corner Relief option tool in the Modify group on the Sheet Metal tab. The default type is square, but you can change it to another type. The icon on the Corner Relief option tool changes to reflect the corner relief type.

Bend Relief. When sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to tear depending on the geometry of the boundary. As a general practice, relief is provided to the flange for ease of bending operation. Benefits of Bend Relief. When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

What Is Bend Relief? In sheet metal, a bend relief is an incision cut along the sides of a planned bend. Though bend relief lengths and widths vary between projects, they all share a common goal: preventing tearing and part deformation during the bending process. During the bending of sheet metal, material around the bend tends to stretch and . Then model your relief as sketch profile and use Cut across Bend to cut it (pictures and R11 part are attached) Lucia Casu Inventor Part ModelingPlasma cutting bend relief cuts for hand bending sheet metal. I'm an absolute 100% newbie to CNC plasma cutting, CAD, and solidworks. I tried Freecad, and Fusion 360, but Solidworks feels like it has just "clicked" for me, particularly with 3D parts, which is what most of my needs are. I've designed a few sheet metal parts, and I'm enjoying .

• For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but require high-cost tooling. [email protected] | 607.227.7070 | www.incodema.com Cut relief between external features. Internal bend relief must SOLIDWORKS Sheet Metal 2018 includes two enhancements to Three Corner Bend Relief, adding solutions for the corner flange challenges Sheet Metal designers run into. Corner Relief Display. SOLIDWORKS 2018 enhancement to the 3 Corner Relief can now display a relief in the folded state when the radius is smaller than the default, whereas 2017 was .

sheet metal dimensioning standards

sheet metal dimensioning guidelines

What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

sheet metal relief|sheet metal dimensioning guidelines