curved sheet metal solidworks A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern. Replace your worn out trigger box, and fixing the slam firing problem caused by worn out trigger sears. This trigger box is compatible with WELL MB01, MB04 and MB05 airsoft sniper rifle. Compatible with TSD Type 96 Series as well.

0 · sheet metal bending in SolidWorks

1 · curved cylinder in SolidWorks

2 · SolidWorks sheet metal round bend

3 · SolidWorks sheet metal flange

4 · SolidWorks sheet metal edge flange

5 · SolidWorks sheet metal cylinder

6 · SolidWorks sheet metal curved bend

7 · SolidWorks fold sheet metal

In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for welding sheet metal so if you want to read it hop in.

Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, .

wholesale cnc metal parts manufacturer

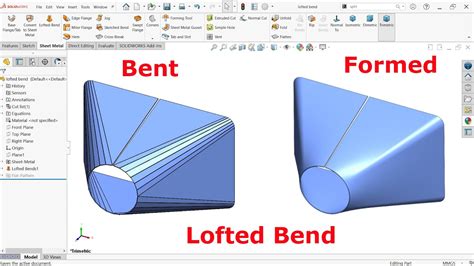

As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to . A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.Easy unfolding of multi-body parts, assemblies, free-form surfaces, curved surfaces, and other complex parts. Multiple import and export (dxf, geo, step, xml) file formats. Reduce design errors and save as much as 80% of the design .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of .

wholesale cnc pvc pipe threading machine manufacturers

In this lesson, you create a sheet metal part. This lesson demonstrates: Creating a base flange ; Adding a miter flange ; Mirroring the part and creating new bends ; Adding an edge flange and editing its sketch profile ; Mirroring a feature ; . Follow tutorials inside Solidworks. One way is to select this surface, then "insert bends", but first you'll need to add some fillet between the 35mm flat and the big radii that aren't tangent to the flat. Yes. Also There is other button .Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved . I'm trying to create a flat pattern of the component in the attached file (similar to a tent). There's no base, just the 3 curved sides and the top. I think the curves are causing the .

wholesale cnc turning parts manufacturer

Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities. As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then you can use those two sketches as your profiles for a lofted bend using the formed manufacturing method. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.Easy unfolding of multi-body parts, assemblies, free-form surfaces, curved surfaces, and other complex parts. Multiple import and export (dxf, geo, step, xml) file formats. Reduce design errors and save as much as 80% of the design time thanks .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features.

In this lesson, you create a sheet metal part. This lesson demonstrates: Creating a base flange ; Adding a miter flange ; Mirroring the part and creating new bends ; Adding an edge flange and editing its sketch profile ; Mirroring a feature ; Adding and bending a tab ; Adding a cut across a bend ; Folding and unfolding bends ; Creating a closed .

Follow tutorials inside Solidworks. One way is to select this surface, then "insert bends", but first you'll need to add some fillet between the 35mm flat and the big radii that aren't tangent to the flat. Yes. Also There is other button for converting bodies as a sheet metal. Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved front face. Please see the plan view on the attached drawing for the curve details.

sheet metal bending in SolidWorks

curved cylinder in SolidWorks

I'm trying to create a flat pattern of the component in the attached file (similar to a tent). There's no base, just the 3 curved sides and the top. I think the curves are causing the problems but I'm really not sure. Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities.

SolidWorks sheet metal round bend

As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then you can use those two sketches as your profiles for a lofted bend using the formed manufacturing method. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.Easy unfolding of multi-body parts, assemblies, free-form surfaces, curved surfaces, and other complex parts. Multiple import and export (dxf, geo, step, xml) file formats. Reduce design errors and save as much as 80% of the design time thanks .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features.

In this lesson, you create a sheet metal part. This lesson demonstrates: Creating a base flange ; Adding a miter flange ; Mirroring the part and creating new bends ; Adding an edge flange and editing its sketch profile ; Mirroring a feature ; Adding and bending a tab ; Adding a cut across a bend ; Folding and unfolding bends ; Creating a closed . Follow tutorials inside Solidworks. One way is to select this surface, then "insert bends", but first you'll need to add some fillet between the 35mm flat and the big radii that aren't tangent to the flat. Yes. Also There is other button for converting bodies as a sheet metal.

Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved front face. Please see the plan view on the attached drawing for the curve details.

wholesale cnc turned parts factories

wholesale cnc parts factories

West Gate Sheet Metal Inc is located at 50 NW 110th St in Okeechobee, Florida 34972. West Gate Sheet Metal Inc can be contacted via phone at 863-824-6132 for pricing, hours and directions. Contact Info

curved sheet metal solidworks|SolidWorks sheet metal cylinder