adjacent box beams aashto distribution two load distribution cases for adjacent box-beam bridge systems: cases (f) and (g). Case (f) considers adjacent beams with shear keys and a concrete deck. Case (g) considers adja-cent . There is a fuse box at your knees inside: And another one called the "Power Distribution Box" is located under the hood on the driver side near the firewall - number 6 in the diagram below: "Central Junction Box" is a term more used for household or industrial wiring, not automotive applications.

0 · precast box beam connections

1 · precast box beam bridge diagram

2 · concrete box beam bridge diagram

3 · box beam connection optimization

4 · box beam bridges

5 · box beam bridge survey

6 · box beam bridge diagram

7 · box beam bridge design

$4.99

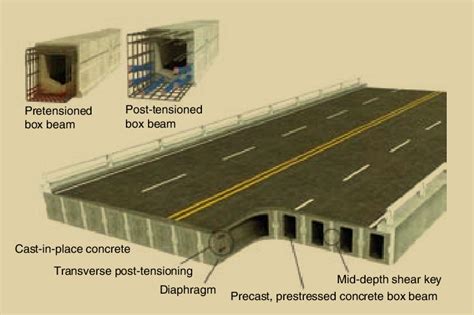

adjacent precast concrete box-beam bridges. n These bridges provide a popular and economical solution in many states because they can be constructed rapidly and deck forming is .two load distribution cases for adjacent box-beam bridge systems: cases (f) and (g). .the connection between adjacent box beams. (3–5) The AASHTO Standard Specifications for High-way Bridges states that “the interaction between the beams is developed by continuous .two load distribution cases for adjacent box-beam bridge systems: cases (f) and (g). Case (f) considers adjacent beams with shear keys and a concrete deck. Case (g) considers adja-cent .

Under NCHRP Project 12-95A, â Proposed AASHTO Guidelines for Adjacent Precast Concrete Box Beam Bridge Systems,â the University of Cincinnati research team was asked to develop . The "adjacent box beam system" is typically more than 21 inches deep. The beams are normally three feet or four feet wide; however, some states have used wider sections. .

In this study, the live-load moment-distribution factors (LLMDFs) were evaluated for an adjacent precast prestressed concrete box beam bridge. The bridge used a new shear .AASHTO LRFO provisions is given. A fully worked numerical design example is included to demonstrate the proposed design procedure. Precast, prestressed concrete box girders are .

hidden camera in junction box

“Live-load moment-distribution factors for an adjacent precast prestressed concrete box beam bridge with reinforced UHPC shear key connections.” J. Bridge Eng. 22 (11): . reduce shear key grout failure (cracking) in PennDOT precast box beam bridges. This objective was met by conducting a state-of-the-practice literature review, numerical .adjacent precast concrete box-beam bridges. n These bridges provide a popular and economical solution in many states because they can be constructed rapidly and deck forming is eliminated. n This information was gathered primarily from a survey of state highway agencies through the AASHTO Highway Subcommitteethe connection between adjacent box beams. (3–5) The AASHTO Standard Specifications for High-way Bridges states that “the interaction between the beams is developed by continuous longi- tudinal shear keys used in combination with transverse tie assemblies which may, or may not, be prestressed”(p. 34).(3) The shear key

Adjacent beams with an asphalt wearing surface shall be considered as precast solid, voided, or cellular concrete box with shear keys and with or without transverse post-tensioning supporting components with an integral concrete deck, typical cross-section (g).two load distribution cases for adjacent box-beam bridge systems: cases (f) and (g). Case (f) considers adjacent beams with shear keys and a concrete deck. Case (g) considers adja-cent beams with shear keys and transverse post-tensioning to provide compression at the longitudinal joint. When evaluat-Under NCHRP Project 12-95A, â Proposed AASHTO Guidelines for Adjacent Precast Concrete Box Beam Bridge Systems,â the University of Cincinnati research team was asked to develop guidelines for the design and construction of various adjacent precast box beam bridge systems to enhance the performance of connections and bridge service life and to . The "adjacent box beam system" is typically more than 21 inches deep. The beams are normally three feet or four feet wide; however, some states have used wider sections. Figure 2.2.3-2 shows cross sections of common butted precast prestressed beams.

In this study, the live-load moment-distribution factors (LLMDFs) were evaluated for an adjacent precast prestressed concrete box beam bridge. The bridge used a new shear key configuration, which was grouted with ultrahigh performance concrete (UHPC) and contained noncontact lap-splice dowel bars.

AASHTO LRFO provisions is given. A fully worked numerical design example is included to demonstrate the proposed design procedure. Precast, prestressed concrete box girders are widely used in short and medium span bridges in North America. Based on the National Bridge Inventory, Dunker and Rabbat showed the change in percentage of the eight most

“Live-load moment-distribution factors for an adjacent precast prestressed concrete box beam bridge with reinforced UHPC shear key connections.” J. Bridge Eng. 22 (11): 04017088. https://doi.org/10.1061/(ASCE)BE.1943-5592.0001127 . reduce shear key grout failure (cracking) in PennDOT precast box beam bridges. This objective was met by conducting a state-of-the-practice literature review, numerical parametric studies, and experimental verification tests.adjacent precast concrete box-beam bridges. n These bridges provide a popular and economical solution in many states because they can be constructed rapidly and deck forming is eliminated. n This information was gathered primarily from a survey of state highway agencies through the AASHTO Highway Subcommitteethe connection between adjacent box beams. (3–5) The AASHTO Standard Specifications for High-way Bridges states that “the interaction between the beams is developed by continuous longi- tudinal shear keys used in combination with transverse tie assemblies which may, or may not, be prestressed”(p. 34).(3) The shear key

Adjacent beams with an asphalt wearing surface shall be considered as precast solid, voided, or cellular concrete box with shear keys and with or without transverse post-tensioning supporting components with an integral concrete deck, typical cross-section (g).

two load distribution cases for adjacent box-beam bridge systems: cases (f) and (g). Case (f) considers adjacent beams with shear keys and a concrete deck. Case (g) considers adja-cent beams with shear keys and transverse post-tensioning to provide compression at the longitudinal joint. When evaluat-Under NCHRP Project 12-95A, â Proposed AASHTO Guidelines for Adjacent Precast Concrete Box Beam Bridge Systems,â the University of Cincinnati research team was asked to develop guidelines for the design and construction of various adjacent precast box beam bridge systems to enhance the performance of connections and bridge service life and to . The "adjacent box beam system" is typically more than 21 inches deep. The beams are normally three feet or four feet wide; however, some states have used wider sections. Figure 2.2.3-2 shows cross sections of common butted precast prestressed beams.

In this study, the live-load moment-distribution factors (LLMDFs) were evaluated for an adjacent precast prestressed concrete box beam bridge. The bridge used a new shear key configuration, which was grouted with ultrahigh performance concrete (UHPC) and contained noncontact lap-splice dowel bars.

AASHTO LRFO provisions is given. A fully worked numerical design example is included to demonstrate the proposed design procedure. Precast, prestressed concrete box girders are widely used in short and medium span bridges in North America. Based on the National Bridge Inventory, Dunker and Rabbat showed the change in percentage of the eight most “Live-load moment-distribution factors for an adjacent precast prestressed concrete box beam bridge with reinforced UHPC shear key connections.” J. Bridge Eng. 22 (11): 04017088. https://doi.org/10.1061/(ASCE)BE.1943-5592.0001127 .

precast box beam connections

Metals Depot - America's Metal Superstore is your complete supplier for industrial metals worldwide. Stocking over 50,000 Shapes, Sizes, Types and Lengths of Steel, Aluminum, Stainless, Brass, Copper, Cold Finish Steel, Tool Steel and Alloy Steels among our network of warehouses, at Wholesale Prices.ReStore carries new and gently used cabinets of all kinds, including filing cabinets, kitchen cabinet sets, pantry cabinets, bathroom vanities, medicine cabinets, and garage cabinets. .

adjacent box beams aashto distribution|box beam bridge survey