7 axis cnc milling machine 7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the . I could see the plastic on the junction box (not really a box - just a covering) melted. I had to twist my body and arms between drain pipes, furnace ducts, etc. to just be able to reach it. Turned out that the 120v wires were connected with wire nuts, and the hot side was the culprit.

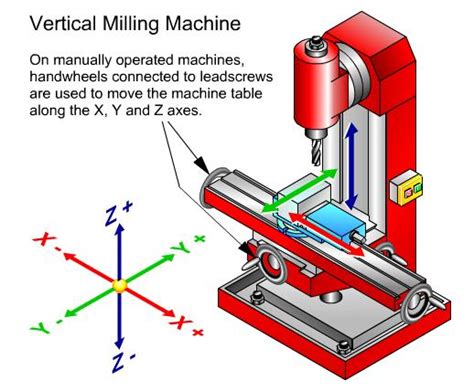

0 · milling machine axis diagram

1 · mill xyz axis

2 · haas vf7 x travel

3 · haas vf7 for sale

4 · cnc mill axis diagram

5 · 7 axis robot arm cnc

6 · 7 axis machining center

7 · 7 axis cnc machine price

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

7-axis CNC machining stands out because it offers unparalleled flexibility and precision. Unlike traditional 3-axis or even 5-axis machines, a 7-axis CNC milling machine can move in seven .

Learn about 7 axis CNC machining, a leading-edge technology that can machine complex parts with high accuracy and flexibility. Compare 7 axis CNC machinin.Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining .

7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the .

CNC Vertical Mill with 84" x 32" x 30" travels All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle. A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, .7-axis CNC machining stands out because it offers unparalleled flexibility and precision. Unlike traditional 3-axis or even 5-axis machines, a 7-axis CNC milling machine can move in seven different directions. This includes the usual X, Y, and Z axes, plus additional rotational and tilting movements around these axes.Due to the multitasking capabilities, complete automation can be achieved with a 7-axis CNC machine. And manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine.

Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part.

CNC Vertical Mill with 84" x 32" x 30" travels All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle.

milling machine axis diagram

mill xyz axis

4 weatherproof junction box specifications

A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, plastics, and composites.Among the various types of CNC milling machines, the 7-axis system holds immense potential. This blog post delves into the world of 7-axis CNC milling machines, exploring their capabilities, applications, and the transformative impact they have on precision manufacturing.The QuickTECH i-42 / i-60 Twin is a compact, high precision, high production CNC mill/turn center cast from Meehanite iron. Available in both 42mm and 60mm bar capacities, this unique bar processing center provides complete part machining including all complex milling functions.

What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X axis for vertical rotation; Y axis for horizontal rotation; Z axis for depth of the part; A axis for X axis revolutionFind your 7-axis machining center easily amongst the 7 products from the leading brands on DirectIndustry, the industry specialist for your professional purchases.7-axis CNC machining stands out because it offers unparalleled flexibility and precision. Unlike traditional 3-axis or even 5-axis machines, a 7-axis CNC milling machine can move in seven different directions. This includes the usual X, Y, and Z axes, plus additional rotational and tilting movements around these axes.

Due to the multitasking capabilities, complete automation can be achieved with a 7-axis CNC machine. And manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine.Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.

7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part.

CNC Vertical Mill with 84" x 32" x 30" travels All large-frame models come with an upgraded features package that includes a side-mount tool changer, chip auger, programmable coolant nozzle, and remote jog handle. A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, plastics, and composites.Among the various types of CNC milling machines, the 7-axis system holds immense potential. This blog post delves into the world of 7-axis CNC milling machines, exploring their capabilities, applications, and the transformative impact they have on precision manufacturing.

The QuickTECH i-42 / i-60 Twin is a compact, high precision, high production CNC mill/turn center cast from Meehanite iron. Available in both 42mm and 60mm bar capacities, this unique bar processing center provides complete part machining including all complex milling functions. What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X axis for vertical rotation; Y axis for horizontal rotation; Z axis for depth of the part; A axis for X axis revolution

4 x 8 aluminum sheet metal

haas vf7 x travel

The Wiremold BW35 junction box is used to connect the NM-B 14/2 cable inside the 2×4 stud wall to NM-B 14/2 cable from the Wiremold® 700 Series metal channel. The BW35 box is removed to expose the back plate.

7 axis cnc milling machine|cnc mill axis diagram