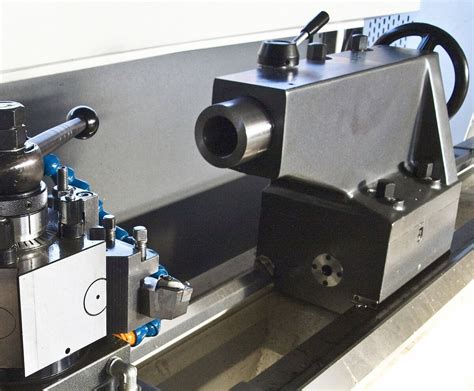

cnc machine tailstock Positioned opposite the headstock on a CNC lathe machine, tailstocks serve to secure and support the free end of a workpiece during machining. They ensure that the longitudinal rotary axis of the workpiece . The Wm. J. Donovan Co. is able to meet the needs of any client and any size project utilizing our state-of-the-art 45,000 square foot facility in Philadelphia, along with a 15,000 square foot warehouse just across the street from our main facility and a 7,000 square foot warehouse and office space in North Wales, PA.

0 · what is a tailstock machine

1 · tailstock for cnc machine

2 · tailstock cutting tool

3 · tailstock cutting machine

4 · manual tailstock

5 · cnc tailstock drilling

6 · cnc tailstock alignment

7 · cnc lathe tailstock

Wiegmann NEMA 3R Screw Cover Wall Mount Enclosure - A perfect outdoor solution where it is used as wiring boxes or junction boxes providing protection from rain, sleet, snow or dripping water. The body and and door are fabricated .

what is a tailstock machine

This video covers a wide array of topics related to using the tailstock on your CNC Turning Center.Some of the subjects we touch on are: length to diameter r.

Positioned opposite the headstock on a CNC lathe machine, tailstocks serve to secure and support the free end of a workpiece during machining. They ensure that the longitudinal rotary axis of the workpiece .

When a CNC machine is equipped with a programmable tailstock, it can provide simple, precise and automatic control of directional movement .This video covers a wide array of topics related to using the tailstock on your CNC Turning Center. Some of the subjects we touch on are: length to diameter ratio, center drilling, choosing a tailstock pressure, dealing with fragile parts, and choosing and maintaining your live center.

The tailstock is an essential component of a CNC lathe that is used to support the workpiece, particularly when it is being drilled or turned between centers. The tailstock provides stability and rigidity to the workpiece, .Discover the Haas SL30T, a robust CNC lathe with tailstock for enhanced stability during machining. Ideal for various industries, this versatile machine offers a range of upgrades and .The tailstock is an indispensable component of CNC machines, providing support, stability, and precision during machining operations. Its contribution to enhanced accuracy, increased . On a CNC machine lathe, the tailstock is used to hold and support the free end of a workpiece while it is being machined. It is situated opposite the headstock. The longitudinal rotating axis of the work piece is retained steady .

tailstock for cnc machine

In CNC lathes, envision the tailstock as a safeguarding companion. The potential for midsection wobble or flexing is significant when machining extended items such as rods or tubes. Enter the tailstock .Lathe tailstock alignment on CNC machinery and equipment. . Tailstock alignment and machine adjustment. There are several ways to align a tailstock which works simliar for any CNC or basic machine. The way below describes adjusting the tailstock when engaged with the part. This removes any backlash from the gib for the tailstock and ensures .This rotary fits this particular machine, but may require alternative fixturing for proper positioning, such as a sub-plate or alternate T-slot. HA5C2-T: VF-1: ALTERNATIVE FIT: CAUTION: ALTERNATIVE FIT: CAUTION: This rotary fits this particular machine, but may require alternative fixturing for proper positioning, such as a sub-plate or .

Hi all, Im having an oldtimers moment. It has been a long time since I needed to use our programmable tailstock on our Hwacheon Cutex 240 with Fanuc 0i-TB control. Please remind me what the M codes for quill advance, as well as quill retract. Thanks in advance. Does anybody know if there is an M-Code that can extend/retract my tailstock. I have a Fanuc 10 control. I know that M-Codes are usually different from machine to machine, but if anyone knows a generic M-code or one they use or the parameter to change to set an M-Code for this, that would be great.Is a tailstock necessary when using a CNC lathe to machine a workpiece? Whether a tailstock is needed or not will depend on the length of the workpiece being machined. If the pieces are short-length, a tailstock may not be necessary. For long, slender pieces — such as rifle barrels — it is important to use a tailstock to achieve accurate .

Machine Type: CNC Lathes Make: Haas Model: ST-40L Year: 2012 . HAAS CNC Control Chip Conveyor Tailstock. All specifications are assumed to be correct but must be confirmed by the purchasing entity. Similar Equipment . 2004 Leadwell LTC-50BXL CNC Lathe, 2004 - .

Do I need a tailstock when using a CNC lathe to machine a workpiece? Maybe — depending on the size of the part. If a short-length piece is being machined, a tailstock may not be necessary. For a long, slender piece — such as rifle barrel — using a tailstock allows for more accurate machining without distortion or chatter. Read more The machine is only 8 years old and has only done an average of 38 hours per week since first commision. The problem I have is slightly embarrasing, however. There is only 12" between the chuck and the tailstock. I know the tailstock can be moved back because I can see the slide marks on the slideway. The only problem is, I don't know how to . This procedure will show you how to install the "tall" Tailstock on the ST-10/15. Applicable to ST-10/15's reboot machines built from September 2018 and on. This procedure applies to the following kit: 93-1000327 - Tailstock Field Install Kit ST-10/15 Note: All images are taken from an ST-10 Lathe, however the procedure will remain the same for an ST-15 Lathe.

CNC Machining . Doosan Puma 300 tailstock programming question. Thread starter drewboyer; Start date Jul 4, 2013; Replies 9 Views 20,181 drewboyer Stainless . When the quill is in this "range" it will send a signal to the control letting the machine know the tailstock is ready. There should be an indicating light on the control that is on . CNC Machining . tailstock to rotary alignment issues. Thread starter MULTUSB200; Start date Apr 10, 2019; Replies 12 Views . was milled flat and than rotated +90 - 90 and checked for parallelism with the machine's X axis. Manipulating the tailstock proved tricky so a fixture was designed to hold the part on a fixture that mounts on the 4th .

Hi, We are considering a new Lynx 2100 LB with hydraulic tailstock to replace one of our older machines. We use the tailstock with a lot of our parts, wondering if someone can explain the operation of the tailstock on this machine. Reseller didnt seem to know too much about it. Does this. I agree; The parameter page will allow you to disable the tailstock. Alternatively, we use M157 on our OSP 5020 control in the beginning of the program to allow machining with the tailstock active. We then use M156 at the end of the program to return it to the default setting.

This is a 1995 Okuma Cadet CNC lathe and has a footswitch with two pedals, one for extend, one for retract. Pedal functions show up working fine on "check data" screen but just can't get any action at all. I switched connectors from headstock valve to tailstock valve and then tailstock works fine, using headstock footswitch, so not hyd solenoid.

tailstock cutting tool

CNCTOPBAOS K12-100mm CNC Router Milling Machine Rotational Axis 4th Axis A axis Rotary Table A axis 100mm 4 jaw chuck dividing head,MT2 65mm Tailstock Reducing ratio 6:1 for CNC Engraving Machine - .The cncmachines.com platform helps you find the used CNC machine that meets your production needs while keeping costs low. With a variety of brands and types of machine tools available, you can easily find what suits your requirements. . Tailstock. Bar Feeder. Parts Catcher. Live Tooling. Sub Spindle. Y Axis. 5 Axis. DELIVERY. Next 30 Days . Hello I run a Haas SL30 Lathe, I program exclusively using Mastercam 2018. I mostly use a CNMG 432 type holder and inserts. Material is Hardened H-13, 3" Dia 7" Long I've never had to use the tailstock to support any parts before. And my problem is that I only have the "entry" level version.Machine Type: CNC Lathes Make: Haas Model: SL-40 Year: 2012 Machine Location: Upon Request Stock #: 479907. . Okuma Captain L-370M CNC Lathe, 2006 - Tailstock, Live Tooling, Chip Conveyor.

I'm looking to buy a CNC lathe (right now looking at Okuma LNC8's, but I'm open to others). At what point do you need a tailstock (what type of part)? I'm basically completely new to turning but I need to complement my CNC mills. The last 5-10 parts I .This procedure shows you how to replace the tailstock pressure adjustment valve on a lathe machine. Hydraulic Tailstock Check Valve Eliminator - Installation: This procedure shows you how to remove the the tailstock dual piloted check valve on a lathe machine built 8/2015 - 9/2018.The Haas fully programmable hydraulic tailstock can be activated via the part program, or controlled directly with the standard foot switch. Closed-loop positioning allows you to stop the tailstock anywhere along its travel. One machine, A Mori Seiki you position the saddle of the machine in s specific position and when you give the tailstock unclamp m code a pin also shoots out into the saddle efectivly locking the tailstock to the saddle and then you use the z axis to move to where ever you want and clamp again.

CNC Machining ABOUT PRACTICAL MACHINIST With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals.

LR-15? It's probably a manual tailstock. If there are two bolts in the front (towards the spindle) and two bolts on the opposite end of the tailstock, just loosen the four bolts, manually position the A-Turret to engage the pin on the tailstock, manually move the tailstock to desired position, dis-engage tailstock pin, re-tighten the four bolts on the tailstock. Standard CNC lathe w/o tailstock doing the work. Is this do-able without a tailstock or too much chatter? tolerance is +/-.002 If its a no-go, I could do a stickout of 2.6, cut the 1/2 inch diameter 2.5 inches long, thread, then pull the stock out the extra bit and part. Would this still create too much flex/chatter? Machine is a 1980 Mori Seiki SL 25B I'm looking for the keep relay to disable the tailstock engagement so I can move it backward and forward in the program. The tailstock need to be manually engage and disengage. At the moment, once the tailstock is engaged (manual handle the couple tailstock with turret) the program will not run. (TAILSTOCK)Tailstock Setover Method: Another method for taper turning on a lathe is the tailstock setover method, where the tailstock is offset by a small amount to create the taper. Conclusion Taper machining is a critical process in CNC machining, requiring careful planning, precise execution, and thorough inspection.

tailstock cutting machine

electrical enclosure components

$15.99

cnc machine tailstock|cnc tailstock drilling