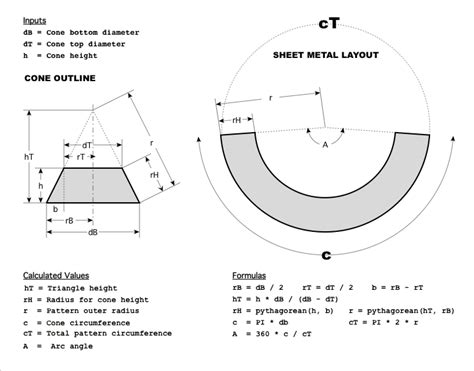

sheet metal cones Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Shop Tangkula 44" Metal Planter Box with Trellis Raised Garden Bed with Trellis, Elevated Lattice Planter for Climbing Plants at Target. Choose from Same Day Delivery, Drive Up or Order Pickup. Free standard shipping with $35 orders.

0 · truncated cone from flat sheet

1 · sheet metal layout cone

2 · sheet metal cone template

3 · sheet metal cone rolling calculation

4 · sheet metal cone fabrication

5 · cone weight calculator in kg

6 · cone sheet metal calculator

7 · calculate weight of cone

Find company research, competitor information, contact details & financial data for TRAPPE SHEET METAL FABRICATION, INC. of Collegeville, PA. Get the latest business insights from Dun & Bradstreet.

truncated cone from flat sheet

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone.

cnc machine shop edmonton

Sheet metal cones are versatile and indispensable in a wide range of applications, from ductwork in HVAC systems to chimney caps and funnels. Whether you need to replace a .The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this .In this way we can generate fabrication layout of Full Cone using Geometrical Method or Graphical Method of Fabrication Layout Development. Numerical Method or Calculation Method for Full Cone Layout

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with . Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I'm here to alleviate your worries and provide you with the correct workflow.Arntzen has over 60 years of steel cone rolling experience, so you can count on us to manufacture your custom metal cone correctly and economically. Contact us today! Arntzen Corporation fabricates concentric cones, eccentric cones, and .

Did some checking this morning and it looks like cones of about 15 degrees on the main cone and 8 degrees on the reverse cone could be a start. I am thinking of doing these as a "roll only" cone and also offering some "sizing gauges". These would be something like .125" thick and have a center hole of 1.50" 2.50" and 3.50". AS 2020 Files Attached. Anyone know how to have an unfolded sheet metal cone get detailed correctly? the results I got are nothing like what I would expect. I need both inside and outside radius plus the correct orientation of dimensions. My customer could not make this simple object with this drawing. Any help is appreciated.Halvorsen rolls, forms, welds and fabricates heavy steel and metal plate to manufacture custom cones, cylinders, segments, hoppers, elbows and transitions. ASME PRESSURE VESSELS • HEAVY PLATE FABRICATION QUOTED ACCURATELY, BUILT PROPERLY, DELIVERED PROMPTLY. 800-423-7080 Get a Quote > Home;Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry. This app helps to Fabrication Engineer, Fabrication Fitter .

Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I’m here to alleviate your worries and provide you with the correct workflow. I typically like to start my first sketch on the Top Plane. Using my sheet metal open sketch technique, we can draw an arc and its construction lines. With the radius (or diameter) dimension .As you can imagine, producing sheet metal cones is an incredibly skilful and precise procedure, but one that we are accustomed to here at CSM, and is another one of the skills we have under our belt.. We’re going to take a look at what applications a metal cone can have, what type of cones it’s possible for CSM to produce for you, and some . Sheet metal rolling is another method of bending steel, but in this case the goal of manufacturing is to achieve a rounded circular bend, under specific radius, rather than a V-shaped angular form. Some of the main purposes of this metal-processing method is to manufacture pipes, ducts and cones, which have non-standard diameters and are needed for . See how to roll a long cone from 16-gauge (1.6mm) sheetmetal.You can help me create new videos by becoming a Patreon. Here’s the link:https://www.patreon.com.

We offer sheet metal rolling for components up to 3 meter wide using a Hydraulic bending Machine capable of manual pinching and cone bending with pre-bending capability. Our skilled engineers are experienced in the rolling of sheet metal in a wide range of shapes. Sheet rolling remains a precision art reliant more on the skill of the engineer than any other manufacturing .Just gave that a try and it worked well. I ended up creating two new sketches on the top planes and drawing two new circles the same size as the original cones, then used those to make a lofted cut and that split the two parts so the flatten function works. This will give you the length of the center line you need from the top of the cone to the intersecting point (A) . Western Sheet Metal, 2406 Hinton Dr, Irving, Texas, 75061 Office: 972-438-7742 Fax: 972-438-2996 Email: [email protected] Email: [email protected]. Hours:

This video shows how to make cones from 1/8-inch (3.2mm) steel, using simple shop-made equipment. You can help me create new videos by becoming a Patreon. He.Arntzen Corporation fabricates concentric cones, eccentric cones, and offset cones. We also press brake form square to round transitions & rectangle to round transitions. Arntzen has years 64 years of steel cone rolling experience, count on us to manufacture your custom metal cone correctly and economically. With 18 plate rolls, Fabricators and OEMs come to Arntzen .A Paper About Sheet Metal Cone Rolling. The cylinder and the cone can be regarded as the cylinder and the cone of the workpiece are rotated 360 degrees around the rotation centerline in the same plane. The bar of the cylindrical workpiece is parallel to the rotation center line, and the busbar and the rotation center of the cone workpiece. Tilt .Cone Layout Development by Marking and Calculation Method with Practical Example. Full Cone is a very common shape in fabrication industry as it is most frequently used shape in fabrication so it is very necessary that every .

Professional Blacksmith Anvil Mandrel Metal Forming Cone. Perfectly fits 1 inch Hardy Hole of an anvil, or can be used in a vise. This Blacksmith Anvil Mandrel Metal Forming Cone will be an extension of your creativity when forging. Designed for productivity and efficiency, allowing easy transitions from forge to anvil.1 piece cone model the cone as a solidbody revolved 359.9deg. Convert to sheet metal by selecting an edge. Leaving the gap allows it to be converted to sheetmetal. 2 piece cone can be revolved 180 deg as a solidbody. Lofting cones does not .cone rolling machine rolling a cone sheet metal【sheet metal cone roller】sheet metal cone rolling The plate roller is a versatile machine that can be utilized to create cone-shaped pieces of metal. Rolling steel plate into cones requires careful preparation and precise execution. In this article, we will explore the process of rolling steel plate intoRolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size you want it to be out of a flat piece of sheet metal.

Our unique metal fabricating capabilities allow us to produce large metal cones and concentric reducers; such as these two piece fabrications, which have a wall thickness of 1 1/4". Looking through the large inside diamater of a sa516 grade 70 . This extensions draws the 2D shape which is required to form a 3D cone (or truncated cone) after it's cut out (of whatever material). It can be used to generate a sheet cutting layout for a (truncated) cone. The extension unfolds a frustum (=truncated cone) or a cone (if cut diameter=0) and generates a sheet cutting layout or flat pattern projection that can be rolled or .

A piece of metal sheet is placed on a rotating mandrel and a spinning tool is used to press the sheet into the desired shape. Spinning is a good option for larger-sized cones made from thick sheet metal. Metal cone manufacturers create cones for a wide variety of industries, including construction, automotive, aerospace, and food and beverage.Find Sheet Metal Cone stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day.

Sheet metal fabrication is an essential skill for anyone working with metal, from hobbyists to professionals. One of the most versatile and useful shapes that can be created from sheet metal is the cone. Cones are used in a wide range of applications, such as roofing, ventilation, and even decorative elements.22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S.

sheet metal layout cone

sheet metal cone template

cnc machine shop store

sheet metal cone rolling calculation

Triangle offers multiple material options for metal works, including cold-rolled steel plate, 304 stainless steel, 316 stainless steel, and aluminum. Our experts will guide you in selecting the most suitable based on your project’s requirements, ensuring both functionality and aesthetic appeal.

sheet metal cones|cone sheet metal calculator