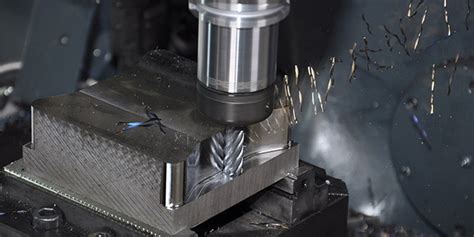

cnc machining stainless steel plate Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running . Thermocraft Engineering uses State of the Art CNC turret punch presses to produce custom sheet metal components which require distinct features such as louvers, offsets, countersinking, electrical knock-outs, rolled ribs or other embossed features.

0 · stainless steel machining tips

1 · stainless steel for cnc

2 · stainless steel cnc machining guide

3 · stainless steel cnc cutting tools

4 · stainless steel cnc cutter

5 · machining stainless steel

6 · cnc machining stainless steel

7 · 303 stainless steel machining

Optimize your parts with RapidDirect's Tumbling Finish Services, offering smooth, burr-free surfaces that enhance durability and appearance. Experience cost-effective processing, quick lead times, and precision designed to meet your specific requirements. What is Tumbling?Whether you’re seeking an off-grid retreat or a vibrant neighborhood, Tumbleweed offers a resource to find tiny home communities across the U.S. Featuring inspiring stories from real .

Stainless steel is one of the preferred materials for CNC machining projects because it requires less maintenance. Stainless steel can withstand harsh environments and a wide temperature range. Compared to . CNC machining creates intricate and precise stainless steel components through computerized automation. This article will delve into the different grades of stainless steel available, covering their advantages and . Stainless steel is one of the most valuable and popular CNC materials manufacturers use in making prototypes and custom parts. It is an alloy with iron, chromium, . Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running .

Stainless steel machining involves shaping and cutting stainless steel using specialized tools and equipment. It involves techniques like milling, turning, drilling, and grinding to create precise components. This method is crucial for . Navigating CNC machining for stainless steel introduces formidable hurdles such as tool wear stemming from the material’s unyielding nature, heat generation impacting the longevity of tools, and the imperative for .Discover the essentials of CNC Machining Stainless Steel, focusing on its types, unique properties, and the specific machining challenges it presents. This guide delves into the best .Stainless steel is an ideal solution for CNC machining. It offers exceptional strength, corrosion resistance, and aesthetic appeal. You can ensure longevity and reliability in your projects by choosing stainless steel, even in the most .

Rally Precision leads CNC machining in stainless steel to produce high-quality, durable parts. Our experts use advanced technology and industry knowledge to tackle stainless steel machining problems with years of experience. Machinability for steel CNC machining is influenced by factors such as hardness, energy, horsepower, and shear stress. Another advantage of CNC steel machining for machine parts is the strong resistance to corrosion and .But, I also know they use multi million dollar, 100,000lbs+ gantry style CNC machine to cut steel and cast iron in factories. That's how some of the 4'x8'/ 5'x10' cnc routers we buy are made. That's how some of the 4'x8'/ 5'x10' cnc routers . CNC Machining: Zinc Plating vs Stainless Steel . When it comes to CNC machining, the choice between zinc-plated and stainless steel depends on the application’s specific requirements. Stainless steel is often preferred for its strength and durability, particularly in high-precision components.

stainless steel machining tips

Warpage like you're describing is a common problem when machining cold finished bars--the rolling process introduces high stresses in the surface of the material and when you machine one side it upsets the balance. Stress relieving will usually fix the problem. All rolled plate, whether mild steel or stainless, can exhibit the same characteristics.

I need to drill a few holes (3 holes per part) in stainless steel 410 alloy. The thickness is 0.032" sheet metal, and the drill diameter is 0.191 (#10 tight clearance fit). The parts will be machined to size, bent to shape, then heat treated. The . What are the Stainless Steel Materials for Sheet Metal Fabrication? The stainless steel grades refer to the distinct compositions and properties of stainless steel alloys, made to suit various applications and conditions. The common grades of stainless steel sheets for metal fabrication are 301, 304, 316, 410, and 430. These grades include a unique percentage of .

I am running a job chamfering the edges of 1/4" 304 plate. 45 degree chamfer down to a sharp edge. I am running a carbide insert chamfering tool ( Nine 9 brand ) at 6500 RPM 24 IPM. I start my cuts at 0.02" width of cut an go down to 0.01, and .008 as the chamfer gets larger. I am chamfering 2.We can offer types of stainless steel machining processes, including CNC machining, sheet stainless steel fabrication, lost wax casting. Get a Quote! www . Contact Us. 0086-755-29354715; [email protected]; Capabilities. CNC Machining Auxiliary Metal Processings Sheet Metal Fabrication Surface . Stainless steel machining creates products and tools for every sector out there. Get Quote. Services. . Some of the popular offerings of 3ERP are CNC machining, rapid tooling, and sheet metal prototyping. The best part when working with 3ERP is the ease of production. You can provide your designs to 3ERP. 3ERP then creates the design with the . Stainless steel is one of the most valuable and popular CNC materials manufacturers use in making prototypes and custom parts. It is an alloy with iron, chromium, and carbon as its primary alloying elements. However, what is CNC machining stainless steel? It involves using computer numerical control to guide the cutting tools that shape stainless [.]

stainless steel for cnc

Stainless Steel Sheet Metal Cut to Size . Companies like Tuofa cnc machining specializing in metal fabrication can provide stainless steel sheet metal cut to the required size and specifications. We offer convenience and efficiency for various projects to cut to stainless steel. How to Cut 1/4 Stainless Steel Plate

Top Quality CNC Milled Custom Brackets, Plates, or Mounts Forster Tool can manufacture your custom bracket, plate, or mount with any number of our vertical or horizontal CNC milling centers! Our machinists have collectively over 100 years of experience under their belt, and that translates to lower cots and smaller lead times for you! We have a job to machine some parts made from steel armor plate (MIL-DTL-12560 Class 1). The hardness is about HRC 35-40. We did the job before and just used end mills that we had on hand which I think were 3/8" ISCAR 4 flute with a 45 degree helix. Both the tool life and cut speed left a lot.

electric box fitting

When it comes to precision machining, two materials stand out: titanium and stainless steel. Both offer unique properties, making them ideal candidates for various applications. In this article, we will explore the future of precision machining and delve into the differences and advantages presented by titanium and stainless steel turned parts.Discover plate machining services available from Brown McFarlane and read the benefits of CNC machining for steel plate. Enquire today for more information. +44 (0)330 221 1106 +44 (0)330 221 1106 . 304 & 304L Stainless Steel Plate; 304H Stainless Steel; 316 -316L Stainless Steel; 321 -321H Stainless Steel; Super Austenitic Stainless Steel .

JB @ C and L Machine Stainless. Joined Dec 26, 2006 Location NJ. Jan 21, 2010 . (T1) with ASTM A514 Constructional Alloy Steel Plate (also T1) The latter is alloyed for good strength with low carbon for welding considerations. It machines like other steels that are around 100K yield as has been noted above. . CNC Machining. ABOUT PRACTICAL . Machining of stainless steel workpiece. Here are the steps of producing CNC machined stainless steel parts; Designing: CAD design with detailed features, dimensioning, and tolerance in computer design software. .My 2600lb bridgeport mill barely handles stainless steel. I’m upgrading to a 5600lb cnc mill. Stainless needs much slower tool speeds because work hardening. You need a healthy chip load as well, so you remove the chip in a big enough piece to take the heat with it.

Fathom offers these materials for stainless steel CNC machining as part of its CNC services: Alloy 302 // Stainless steel 302 is a high carbon alloy. 302 is known for its machinability, toughness, and corrosion resistance. Applications of stainless steel 302 include cryogenic components, items for food and beverage use, and pressure vessels.There is nothing available off the shelf that will mill Stainless steel on a desktop machine. You would have to build a custom machine. Or convert a vertical mill. If you are looking to produce accurate parts with good surface finishes with realistic . Q: Can both thin and thick stainless steel sheet metal parts be subjected to laser cutting? A: Yes, thin sheets and thick ones can all be laser cut when machining stainless steel sheet metal parts using fiber lasers since this method is quite flexible and depends on what needs attention most at any given time.

stainless steel cnc machining guide

Cutting tools . The Benefits of Milled Steel . Machined stainless steel offers advantages that make it suitable for a range of uses. Some of these benefits include: Stainless steel milling offers control over shape, size and reduces the risk of errors which increases the overall precision and efficiency, which is required for automotive, aerospace, and other manufacturing industries.This can be achieved by immersing stainless steel in a sulfuring acid and chromium oxide bath while optimizing other parameters like bath temperature, immersion time, etc. The color changes with time in the order champagne, blue, bronze, gold, rose gold, red and green. Black oxide stainless steel . Figure 2: Black oxide stainless steel screws

CNC machining of stainless steel is used to produce a variety of parts in the medical industry, robotics, food and beverage industry, aerospace, and any industry that requires high-strength applications. . Data Sheet: Stainless Steel 316: 85 ksi: 56%: 81 HRB: Data Sheet: Stainless Steel 17-4PH: 150 ksi: 8%: 33 HRC: Data Sheet: Stainless Steel . Steel CNC Machining involves the use of computer numerical control (CNC) machines to manipulate steel, one of the most robust materials in the manufacturing industry, into desired shapes and sizes. . Bending reshapes steel sheets, tubes, or plates using CNC press brakes or other bending machines, introducing precise angles and curves without . High Efficiency Milling. High Efficiency Milling can be a very effective machining technique in stainless steels if the correct tools are selected.Chipbreaker roughers would make an excellent choice, in either 5 or 7 flute styles, while standard 5-7 flute, variable pitch end mills can also perform well in HEM toolpaths.. HEV-5. Helical Solutions offers the HEV-5 end mill, which . Does anyone have any experiance tapping Armor Plate? Its type IAW MIL-A-12560 Class 1. Its 3/8" thick. They tell me its like tapping stainless steel. I have machined plenty of materials, but i am new to this stuff. The holes will ange in size from 5/16-18 to 1/2"-13. What kind of tap life would.

stainless steel cnc cutting tools

stainless steel cnc cutter

machining stainless steel

Each package contains six 1.25 fl.oz. bottles of dimensional fabric paint in trendy color combinations and finishes, and each bottle of paint is .

cnc machining stainless steel plate|stainless steel cnc machining guide