formability test for sheet metal A variety of forming tests are available for evaluating sheet metal deformation properties and proper selection of quality tests is very much essential in this regard. HGTV.com has inspirational pictures, ideas and expert tips on stainless steel kitchen cabinets so you'll know what to expect from this alternative material.

0 · sheet metal formability testing

1 · formability of sheet metal

If you've ever taken a leisurely stroll through the historical side of town, you may have noticed some strange metal shapes on the sides of brick houses. At first, these metal pieces may seem like some oddly-hung décor or .

sheet metal formability testing

Sheet metal forming operations are so diverse in type, extent, and rate that no single test provides an accurate indication of the formability of a material in all situations. This article presents an overview of types of forming, formability problems, and principal methods of measuring .

In this chapter, sheet-metal formability tests, such as the tensile test, the plane-strain test, and the in-plane stretching test are analyzed.

Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic Bulge Test,. A variety of forming tests are available for evaluating sheet metal deformation properties and proper selection of quality tests is very much essential in this regard.

Industrially rolled samples were tested for fracture criterion, stretch-flangeability, deep drawability and stretch formability through the formability limit diagram, hole expansion ratio,. Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic . Formability is the ability of a sheet material to deform without failure or fracture. Information on formability helps process and tool design engineers predict failure during analysis of sheet metal forming processes for tool design. Formability is a critical material property in describing deformation ability of sheet metals, and it is usually evaluated by a forming limit diagram (FLD) determined at various .

formability of sheet metal

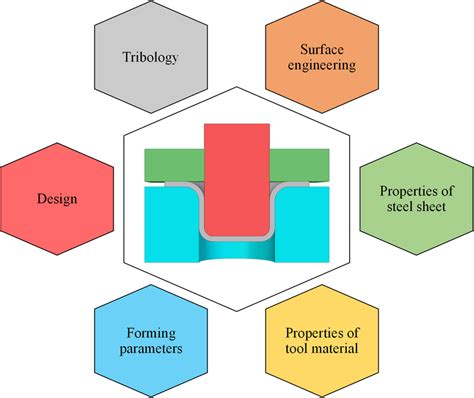

The formability of sheet metal can be defined as the ability of a sheet to be drawn into cups or other desired shapes. It depends upon several factors such as yield strength, strain.Overview of materials and treatment aspects of manufacturability of sheet metal. Written by an industrial expert turned scientist. Concentrates on the formability of sheet metal, one of the fundamental form material is used in metalworking. Formability of sheet metal can be evaluated by various tests like swift cup drawing test, fukui's conical cup drawing test, erichsan cupping test, osu Formability Test, Hydraulic Bulge Test, Duncan Friction Test. These tests are widely used to evaluate of formability for different sheet metals. In this paper, swift cup and erichsen cupping .

In this chapter, sheet-metal formability tests, such as the tensile test, the plane-strain test, and the in-plane stretching test are analyzed.The FEM and experimental methods were used in order to demonstrate how two-dimensional in-plane simulation can help interpret and develop such tests, as well as to understand the nature of material behavior and governing mechanics.So that sheet metal blank should be formed into the desired shaped component. This can be achieved by various sheet metal operations. Before forming the sheet metal blank into the desired shaped component it is necessary to know its formability. Erichsen cup .and longitudinal strain and is a measure of sheet metal drawability. ASTM E517 Standard Test Method for Plas-tic Strain Ratio r for Sheet Metal governs it’ s determina-tion. Because rolled sheet metals develop planar anisot-ropy, the test specimens are cut at 0o, 45o and 90o, respec-tively to the roll direction. The average ratio r avg, is .

The formability is the capability of sheet metal to undergo plastic deformation to a given shape without defects. The defects have to be considered separately for the fundamental sheet metal forming procedures of deep-drawing and stretching. . Hygren G (1959) Investigation into the accuracy of the Erichsen cupping test. Sheet Metal Industries .

FIGURE 4: Olsen test 030026-3 Fukui’s conical cupping test Fukui’s conical cup test is one of the formability evaluation test of sheet metal. The diametrical ratio, maximum forming load, depth of cup is evaluated. This test is related to sheet drawing. The conical cupping test can be performed without blankholder and used to determine .The cupping test is a test method applied in the metalworking industry and is used to determine the ductility of sheet metals and strips. For the performance of cupping tests on sheet metal a spherical drawing punch is pressed into a clamped metal sheet until a crack appears. The cupping test is used to assess drawing formability. A new sheet metal testing procedure has been developed that is simple to perform and that an serve as an adjunct to tensile testing for valuating formability of lots of sheet metal. The new sheet .

18 Formability Tests; 19 Sheet Metal Properties; Index; References; Get access. Share. Cite. Summary. There are many tests of formability for sheet materials. A given test may correlate well with behavior in one type of forming process and poorly with behavior in another. This is because the relative amounts of drawing and stretching vary from .Sheet metal forming operations consist of simple bending, to stretching to deep drawing of complex parts. The mechanical properties of the sheet material greatly influence its formability, which is a measure of the amount of deformation the material can withstand prior to fracture. This blog post covers important definitions determining sheet metal characteristics, the test

All sheet metal forming operations are combinations of stretching, bending and drawing. . (LDH) test has been proposed as a laboratory formability test showing good correlation with press formability. Rectangular blanks of various widths are rigidly clamped in the longer direction and stretched by a hemispherical punch. Transverse constraint .formability Material stretched into shape •Stretch forming – very cheap tooling, net thinning, slow, low formability •Super-plastic forming – cheap tooling, net thinning, expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr 0.3-4pts/hr

The strain path dependence of forming limit curve (FLC) restricts its practical application for formability evaluation as the real strain path of material point in true industrial forming processes is often non-linear. In this work, the constraint equation for material necking was extended to the loading condition with non-linear strain path change and an analytical .

The formability of steel sheet is related to various microstructural features of the sheet. The article describes some of the forming characteristics of the more commonly used formable grades. It also lists the typical mechanical properties for common grades of . The present paper aims at proving this statement. The future research in the field of sheet metal formability will be focused on developing and refining the polycrystalline and ductile damage models, as well as improving the capability of M-K models to give accurate predictions under realistic forming conditions including non-linear strain paths. The formability limit by wrinkling in sheet metal forming is given by the wrinkling-limit curve (WLC) located in the lower left-hand of the second quadrant of principal strain space . . At least three repetitions were made for each formability test in order to ensure reproducibility of the results. The measurements of the specimens were . The majority of such sheet-metal industrial splitting failures occur near to the plane-strain state. Therefore, sheet-metal industries have always been looking for an “ideal” formability test which allows them to evaluate sheets for their ability to resist splitting failures under near plane-strain conditions.

Fukui’s conical cup test is one of the formability evaluation test of sheet metal. The diametrical ratio, maximum forming load, depth of cup is evaluated. This test is related to sheet drawing.Stress state and metal formability. Finally, the metal formability also depends on the state of stress on a metal during forming. The state of stress depends on the shape of the component being fabricated and the process used to form the component. Forming limit diagrams are used to predict whether the forming strains to which a metal will be .Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage).. Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping .test specimen from a sheet Geometry of tensile test specimen according to DIN EN 10 002 - 20*80 Preparing Tensile Test Specimen from a Sheet 3701.01.02 Source: IfU - Stuttgart alu Training in Aluminium Application Technologies For conducting tensile tests on sheets, non-proportional flat specimens with heads

The intrinsic formability of sheet metal is often restricted by the appearance of the plastic flow localization during straining. The sheet metal will fail when the critical limit strain approaches, which is always characterized by the forming limit curve (FLC) plotted in the forming limit diagram (FLD). . Uniaxial tensile test results of .

Evaluating sheet metal formability through the use of tensile tests is an effective technique to correctly and accurately assess a material's properties. . To correctly and accurately capture the mechanical properties of material for use in simulation, a tensile test is performed. The testing procedure is further explained in this article:Concentrates on the formability of sheet metal, one of the fundamental form material is used in metalworking. Part of the book series: SpringerBriefs in Applied Sciences and Technology . The Tensile Test. Wilko C. Emmens; Pages 7-14. Download chapter PDF The Forming Limit Curve. Wilko C. Emmens; Pages 15-24. Download chapter PDF Forming limit diagram (FLD) is one of the most useful tools to evaluate the formability of sheet metals, which was originally proposed by Keeler [1] for the negative minor strain region, and then extended by Goodwin [2] for the positive minor strain region. The out-of-plane [3], [4] and in-plane [5], [6] formability tests, as two primary experimental methods, have .FIGURE 4: Olsen test 030026-3 Fukui’s conical cupping test Fukui’s conical cup test is one of the formability evaluation test of sheet metal. The diametrical ratio, maximum forming load, depth of cup is evaluated. This test is related to sheet drawing. The conical cupping test can be performed without blankholder and used to determine .

The prediction of the sheet metal forming limits assumes primary importance, even if the material formability cannot be easily quantified since it depends on many interacting factors related to both the sheet metal under deformation and the applied process parameters [26]. The first attempt to predict the forming limits was the phenomenological .

buy metal lunch boxes online

Beach style blue two-story house exterior photo in Miami with a hip roof, a metal roof and a white roof

formability test for sheet metal|sheet metal formability testing