bent sheet metal manufacturing This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. 4-axis machining introduces a new dimension of precision and versatility in CNC machining. By adding a rotary axis to the traditional X, Y, and Z axes, 4-axis CNC machines can handle parts from more angles and with greater efficiency.Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage.

0 · types of bending sheet metal

1 · sheet metal cutting and bending

2 · sheet metal bending near me

3 · sheet metal bending dies

4 · maximum thickness sheet metal bending

5 · hand bending sheet metal

6 · bending tool for sheet metal

7 · bending galvanized sheet metal

Electricity Saving Boxes (aka Power Saver devices) are small devices that can be plugged into a home AC socket, or to the electrical panel of the house, and are supposed to work on magically reducing the electric bill all the way up to 50%.

Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .

Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with .

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision .

Bending is an important process in sheet metal fabrication process. In this guide, I will explain everything you should know about sheet metal bending process. If you want to be an expert in metal bending parts, read this guide to . Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.

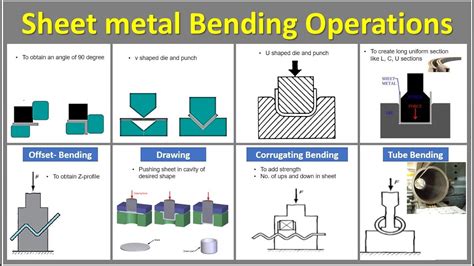

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final .

Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with complex geometries, they usually turn to CNC machining, stamping, or forging for their metal parts.Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

1965 impala sheet metal parts

Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision and efficiency. Bending is an important process in sheet metal fabrication process. In this guide, I will explain everything you should know about sheet metal bending process. If you want to be an expert in metal bending parts, read this guide to the end.

Features of sheet metal bending design Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent without causing damage, cracking, or deforming. 2.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

1960's metal lunch boxes

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal bending is a critical process in modern manufacturing, with material selection playing a pivotal role in product performance and cost-effectiveness. This section explores the most prevalent metals used in sheet metal bending, detailing their properties, applications, and unique characteristics that influence formability and final . Sheet metal bending is one of the most fundamental fabrication processes in the metal manufacturing industry. It’s also one of the most underrated. When product developers and engineers need components with complex geometries, they usually turn to CNC machining, stamping, or forging for their metal parts.Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).

This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision and efficiency.

types of bending sheet metal

sheet metal cutting and bending

1964 chevelle sheet metal

When it comes to completing electrical projects, a 4-way junction box can be a powerful tool. Not only does it provide a safe and secure way to route electrical power throughout a home or commercial property, but it also ensures that the .

bent sheet metal manufacturing|bending galvanized sheet metal