electrical outlet box minimum dimensions Building codes dictate specific height and spacing measurements for receptacles and switches. Learn what the most common dimensions are and why. Building codes are full of maximum and minimum dimensions, and in most cases they .

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications.

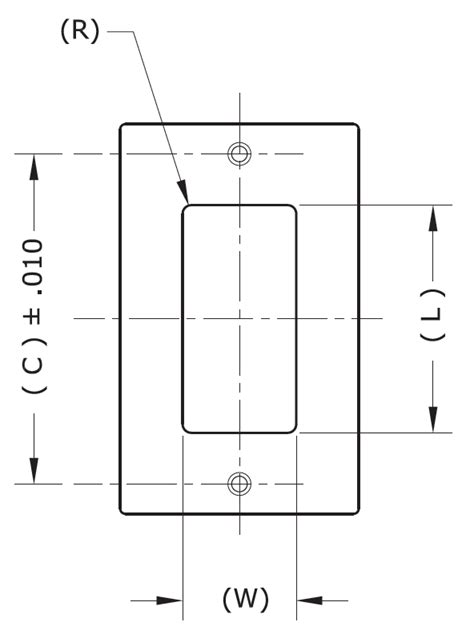

0 · typical outlet dimensions

1 · standard electrical outlet cutout size

2 · standard electrical box size chart

3 · single gang outlet box dimensions

4 · single gang electrical box dimensions

5 · single gang box dimensions standard

6 · electrical metal box size chart

7 · 1 gang outlet box dimensions

The standard method for specifying the dimensions of a American Standard Steel Channels is like C 5 x 9. which is a beam 5 inches deep with a weight 9 lb/ft. I-shaped cross-section beams: Britain : Universal Beams (UB) and Universal Columns (UC)

Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and .The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. In kitchens, electrical outlets should be placed no farther than 48 inches apart, so that no point on the countertop is more than 24 inches away from a receptacle. Any countertop 12 inches wide or more should have an outlet on .

The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier .Building codes dictate specific height and spacing measurements for receptacles and switches. Learn what the most common dimensions are and why. Building codes are full of maximum and minimum dimensions, and in most cases they . Outlet box sizing applies to every outlet box. But junction box and pull box calculations are required only when the conductors are 4 AWG or larger; straight pulls, angle pulls, and U-pulls all affect how big that box must be. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on .

The National Electrical Code Article 314 contains complete details and tables of electrical box sizes in dimensions and cubic inches and should be consulted for complete accuracy because the actual size of the box required, .A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B).The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. In kitchens, electrical outlets should be placed no farther than 48 inches apart, so that no point on the countertop is more than 24 inches away from a receptacle. Any countertop 12 inches wide or more should have an outlet on the wall behind the countertop.

The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier to connect and secure the wires.Building codes dictate specific height and spacing measurements for receptacles and switches. Learn what the most common dimensions are and why. Building codes are full of maximum and minimum dimensions, and in most cases they aren’t just random numbers. Learning the reasoning behind the dimensions is a great way to remember them. Outlet box sizing applies to every outlet box. But junction box and pull box calculations are required only when the conductors are 4 AWG or larger; straight pulls, angle pulls, and U-pulls all affect how big that box must be. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

The National Electrical Code Article 314 contains complete details and tables of electrical box sizes in dimensions and cubic inches and should be consulted for complete accuracy because the actual size of the box required, in cubic inches, depends on the number of wires that will be within that enclosure.A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box. Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B).

The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. In kitchens, electrical outlets should be placed no farther than 48 inches apart, so that no point on the countertop is more than 24 inches away from a receptacle. Any countertop 12 inches wide or more should have an outlet on the wall behind the countertop.

The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier to connect and secure the wires.Building codes dictate specific height and spacing measurements for receptacles and switches. Learn what the most common dimensions are and why. Building codes are full of maximum and minimum dimensions, and in most cases they aren’t just random numbers. Learning the reasoning behind the dimensions is a great way to remember them. Outlet box sizing applies to every outlet box. But junction box and pull box calculations are required only when the conductors are 4 AWG or larger; straight pulls, angle pulls, and U-pulls all affect how big that box must be. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

stamped metal trim on exterior house

typical outlet dimensions

standard electrical outlet cutout size

standard electrical box size chart

There are several types of CNC machine motors, including stepper motors, servo motors, DC gearmotors, and AC gearmotors. Each has its own set of pros and cons, allowing you to choose the right motor for your specific application.

electrical outlet box minimum dimensions|single gang electrical box dimensions