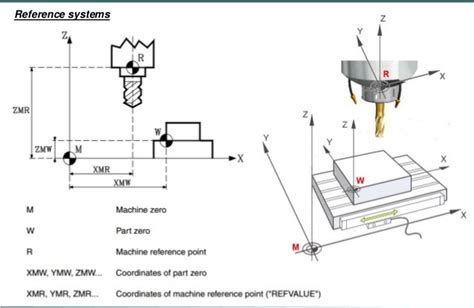

cnc machine reference point The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine . Crafted from durable pre-galvanized steel, these boxes are designed to house wiring devices such as switches or outlets. With RACO's Switch Electrical Boxes, convenience is key. The device mounting holes are pre-tapped to accept 6-32 device screws, making installation a breeze.

0 · unity cnc reference point

1 · setting a reference point in cnc

2 · reference point in cnc

3 · cnc offsets formula

4 · cnc offsets

5 · cnc offset machine reference

6 · cnc offset function

7 · cnc machine reference

SUPER MATERIAL FOR DURABILITY—Powder coated steel for durability-resists of rusting, chipping and cracking. Steel construction epoxy finish. Heavy Duty, holds up to 550 lbs. EASY TO INSTALL—Sold In Pairs (2*24 inch Shelf Foldable Brackets). Quick and easy to set-up/install.

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and .The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the .The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine . stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal .

The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the .

Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual .Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and . The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining . Machine reference point. Every CNC machine has its own origin point or Home location that will serve as the machine’s coordinate system’s origin. The machine reference .

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and consistency in the machining process.The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the complete machine measuring system .The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine comes to know its current axis position.A machines reference position or home position, as it is sometimes referred to, is the point at which all 3 axes read Zero. This is usually set as far as the machine can move in a positive direction in all 3 axes.

r&d metal fabrication

stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal uses software limits and position the table in mid travel as the zero position.other than the Z axis. The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the machine tool manufacturer in each feed axis, and the coordinate value of the fixed position point has been recorded in the . Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual position does not normally change.

The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning.Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools. The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining operations. It is typically set at the extreme end of each .

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and consistency in the machining process.

The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the complete machine measuring system .The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine comes to know its current axis position.A machines reference position or home position, as it is sometimes referred to, is the point at which all 3 axes read Zero. This is usually set as far as the machine can move in a positive direction in all 3 axes. stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal uses software limits and position the table in mid travel as the zero position.other than the Z axis.

The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the machine tool manufacturer in each feed axis, and the coordinate value of the fixed position point has been recorded in the . Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual position does not normally change.The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning.

unity cnc reference point

setting a reference point in cnc

Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools.

rack and pinion cnc machine

$8.56

cnc machine reference point|cnc machine reference