cnc machine gcode CNC G-codes & M Codes for milling and turning with explanations, . When to Use Plastic Junction Boxes. Plastic junction boxes are great for many home projects and smaller jobs where heavy-duty materials are not needed. Let’s look at the best times to use them. Best Applications for Plastic Junction Boxes. Plastic boxes are perfect for simple indoor electrical projects. Here’s when you should consider using .

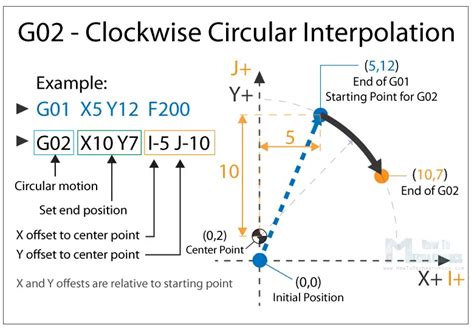

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

When your CNC machine needs a specific component, you shouldn't have to wait. At Anderson America, we make the parts request process as simple and efficient as possible. With our extensive inventory covering 98% of all parts, you can be confident that we have what you need.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc .

G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to . CNC G-codes & M Codes for milling and turning with explanations, .

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow. Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t .

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a .G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M .

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc machine to gain a better understanding of g-codes.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

stainless steel freezer enclosures

how to understand g code

Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a .G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or performing a specific operation. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc machine to gain a better understanding of g-codes.

I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow. Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code.

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a .

g code explained with examples

stainless steel fridge brown cabinet

$32.97

cnc machine gcode|cnc machine g code list