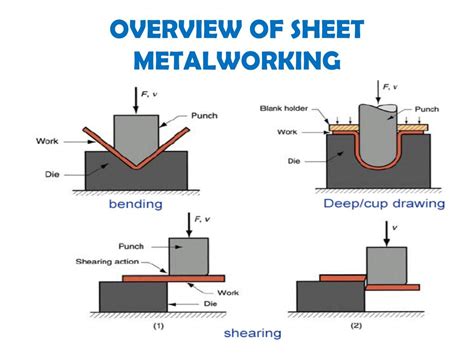

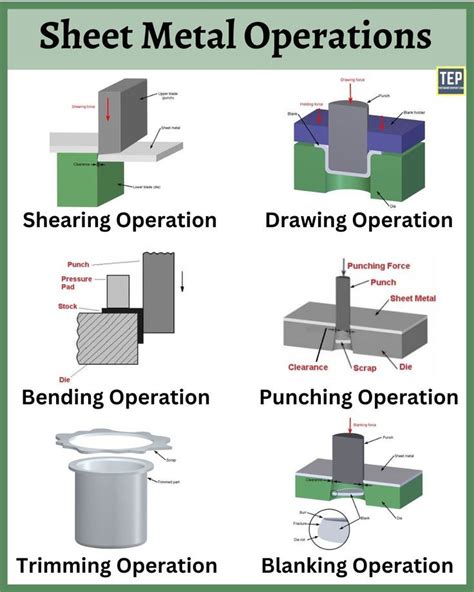

coining process in sheet metal animation This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing. In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various .

0 · sheet metal working processes

1 · sheet metal operations pdf

2 · sheet metal coining process

3 · sheet metal coining machine

4 · sheet metal coining formula

5 · coining sheet metal video

6 · coining sheet metal bending

7 · coining sheet metal

Junction boxes like that one are 8-32. Ground screws are 10-32. Also, you could buy a ceiling hugger style fan instead of a stem mounted one, .

sheet metal working processes

#CUPOLA#CASTING#WELDING In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.

amazon.com shelf brackets metal

This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation .

Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several .Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for .

Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it . Also using a press brake is the bending process known as coining. Coining is a high-performance bending process that’s characterized by greater force. Like air bending, it compresses sheet metal between a top die .#CUPOLA#CASTING#WELDING

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o. This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.

Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation. Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products.Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press.

Also using a press brake is the bending process known as coining. Coining is a high-performance bending process that’s characterized by greater force. Like air bending, it compresses sheet metal between a top die and a bottom die.#CUPOLA#CASTING#WELDINGIn this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.

This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation.

Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products.Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press.

sheet metal operations pdf

sheet metal coining process

amazon sheet metal

sheet metal coining machine

There are several types of rivets available. They are simply classified into the following categories. 1. Solid Rivets. Solid rivets are one of the most common and dependable types of fastening. Solid rivets are made comprised of a simple shaft and head bent with a hammer or rivet gun.

coining process in sheet metal animation|sheet metal coining formula