cnc machine ar 15 lower After I found the solid model file for the AR-15 lower receiver, I knew what I wanted to do could be done. I spent many hours coming up with a game plan of how I was going to machine the . What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or stainless steel metal sheets are too thin, we recommend that you use the TIG technique.

0 · finishing an 80% ar lower

1 · cnc machine for ar lower

2 · ar 15 lower milling machine

3 · ar 15 lower cnc file

4 · 80% lower receiver milling machine

5 · 80% lower receiver mill out

6 · 80% lower cnc machine

7 · 80 percent lower milling machine

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.

finishing an 80% ar lower

In this tutorial I will demonstrate how easy it is to complete an 80% AR15 lower receiver using the CNC Gunsmithing jig. www.cncguns.com You may have seen some of the other projects I’ve . To CNC mill an AR-15 lower receiver, you will need to first secure a block of aluminum into your CNC machine, then use a CAD/CAM software to program the milling .

nuclear day metal sheet

After I found the solid model file for the AR-15 lower receiver, I knew what I wanted to do could be done. I spent many hours coming up with a game plan of how I was going to machine the . But this CNC mill, sold by Wilson’s organization known as Defense Distributed for ,200, is designed to create one object in particular: the component of an AR-15 rifle known as its lower. CNC machining a raw billet of 6061 aluminum into an 80% lower receiver for an AR-15 rifle. This was done on our Haas Automation TM-1 CNC milling machine that.

The Ghost Gunner 3 is a fully automated CNC machine that is capable of producing a wide range of firearms, including AR-15s, 1911s, and Glocks. The machine is designed to be easy to use, with a user-friendly .Number One AR15 lower receiver jig & CNC tooling, The 5 ways of completing your AR15 build. AGT's tooling increases productivity and lowers tooling cost.

Weaponeer has documented ar15 lowers built out of wood and hdpe cutting board. The lower is not a high stress part. The high stress area of the lower is the bridge between the buffer tube attachment and above the . Machining an AR-15 lower receiver is a complex process that requires precision and caution. Below, you’ll find a concise guide on how to machine an AR-15 lower receiver. Is .Ghost Gunner is a general purpose CNC mill that enables a growing library of gunsmithing applications. Engrave, customize, and finish 80 percent lowers to completion. The Ghost Gunner 3-S is fully open, fully programmable and can mill anything you want to make. Cut shapes from flat metal. Engrave designs. Machine blocks into functional items.

In this tutorial I will demonstrate how easy it is to complete an 80% AR15 lower receiver using the CNC Gunsmithing jig. www.cncguns.com You may have seen some of the other projects I’ve completed using CNC machining centers. To CNC mill an AR-15 lower receiver, you will need to first secure a block of aluminum into your CNC machine, then use a CAD/CAM software to program the milling process, and finally, carefully remove excess material to create the lower receiver.After I found the solid model file for the AR-15 lower receiver, I knew what I wanted to do could be done. I spent many hours coming up with a game plan of how I was going to machine the lower receiver. But this CNC mill, sold by Wilson’s organization known as Defense Distributed for ,200, is designed to create one object in particular: the component of an AR-15 rifle known as its lower.

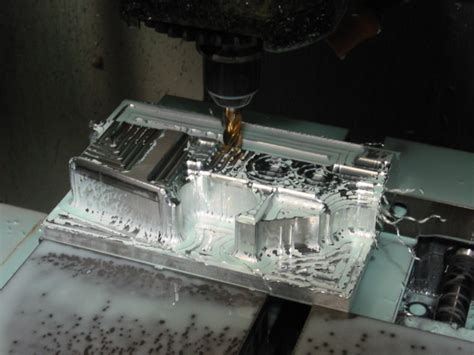

CNC machining a raw billet of 6061 aluminum into an 80% lower receiver for an AR-15 rifle. This was done on our Haas Automation TM-1 CNC milling machine that. The Ghost Gunner 3 is a fully automated CNC machine that is capable of producing a wide range of firearms, including AR-15s, 1911s, and Glocks. The machine is designed to be easy to use, with a user-friendly interface and pre-loaded design files that allow users to start producing firearms right away.Number One AR15 lower receiver jig & CNC tooling, The 5 ways of completing your AR15 build. AGT's tooling increases productivity and lowers tooling cost. Weaponeer has documented ar15 lowers built out of wood and hdpe cutting board. The lower is not a high stress part. The high stress area of the lower is the bridge between the buffer tube attachment and above the selector switch.

Machining an AR-15 lower receiver is a complex process that requires precision and caution. Below, you’ll find a concise guide on how to machine an AR-15 lower receiver. Is this article helpful to you? 1. Is it legal to machine your own AR-15 lower receiver?Ghost Gunner is a general purpose CNC mill that enables a growing library of gunsmithing applications. Engrave, customize, and finish 80 percent lowers to completion. The Ghost Gunner 3-S is fully open, fully programmable and can mill anything you want to make. Cut shapes from flat metal. Engrave designs. Machine blocks into functional items.In this tutorial I will demonstrate how easy it is to complete an 80% AR15 lower receiver using the CNC Gunsmithing jig. www.cncguns.com You may have seen some of the other projects I’ve completed using CNC machining centers.

To CNC mill an AR-15 lower receiver, you will need to first secure a block of aluminum into your CNC machine, then use a CAD/CAM software to program the milling process, and finally, carefully remove excess material to create the lower receiver.After I found the solid model file for the AR-15 lower receiver, I knew what I wanted to do could be done. I spent many hours coming up with a game plan of how I was going to machine the lower receiver. But this CNC mill, sold by Wilson’s organization known as Defense Distributed for ,200, is designed to create one object in particular: the component of an AR-15 rifle known as its lower.CNC machining a raw billet of 6061 aluminum into an 80% lower receiver for an AR-15 rifle. This was done on our Haas Automation TM-1 CNC milling machine that.

The Ghost Gunner 3 is a fully automated CNC machine that is capable of producing a wide range of firearms, including AR-15s, 1911s, and Glocks. The machine is designed to be easy to use, with a user-friendly interface and pre-loaded design files that allow users to start producing firearms right away.Number One AR15 lower receiver jig & CNC tooling, The 5 ways of completing your AR15 build. AGT's tooling increases productivity and lowers tooling cost. Weaponeer has documented ar15 lowers built out of wood and hdpe cutting board. The lower is not a high stress part. The high stress area of the lower is the bridge between the buffer tube attachment and above the selector switch.

cnc machine for ar lower

ar 15 lower milling machine

nylon metal fabric

ar 15 lower cnc file

We have experience welding all forms of metal, including: Steel; Aluminum; Copper; Bronze; Stainless; Brass; Iron; TitaniumMetal fabrication is an essential manufacturing process and The Federal Group has the capability of shaping metal in a number of ways using state of the art equipment. Below are some of the common metal fabrication processes that we specialize in. See more

cnc machine ar 15 lower|finishing an 80% ar lower