sheet metal stamping process quotes Request a Metal Stamping Quote. Our state-of-the-art facility offers custom metal stamping parts with advantages over our competitors. Learn how Winco can help you today! Master the art of how to weld sheet metal with our comprehensive guide. Learn safety, techniques, best practices, and tips for welds.

0 · steel stamping process

1 · sheet metal stamping steps

2 · sheet metal stamping services

3 · sheet metal stamping process

4 · sheet metal stamping examples

5 · sheet metal stamping

6 · metal stamping process examples

7 · how to quote sheet metal

Best Metal Fabricators in Dayton, OH - MacLean Fabrication, Robert's Welding, Joe's Welding And Small Engine Repair, Wicked Welding, Bailey Welding, Weiler Welding, Dixie Fence, Pro Fab Welding Service, Selway Ornamental Iron, Mil-Mar Century Corporation

Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient .Stamping Process in Sheet Metal. The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and . Sheet Metal Quotes. Highly Durable Metal Parts. Precise Components with Tight Tolerances. Variety of Metals & Alloys with Unique Properties. GET YOUR 30 SECOND .Request a Metal Stamping Quote. Our state-of-the-art facility offers custom metal stamping parts with advantages over our competitors. Learn how Winco can help you today!

Metal casting, metal molding and plastic molding processes are also provided. With 17 years of manufacturing and engineering components, Trident Components is an industry leader in .

1. Material Selection. The choice of material is the foundation of your design. Factors like strength, ductility, formability, corrosion resistance, and cost must be carefully .Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and .

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting .The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. Stamping machines and dies are used to achieve this. It’s fascinating. Seeing a simple .

steel stamping process

Stainless Steel Precision Sheet Metal Stamping Parts: Keyword: Stainless Steel Stamping Parts: Material: Stainless Steel / Metal: . Metal stamping parts can process parts of various sizes and . Read More. Introduction. Nanpi .Welcome to contact with us if you have sheet metal parts want to custom make:Email: [email protected]: +86 13727008794#SheetMetalStamping#MetalStampi. Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan.

Stamping: Stamping is a cold working metal cut process. It involves cutting and forming operations to generate intricate forms rapidly. Stamping press and die are used in forming metals like aluminum, copper, and steel. . You can call or email Prolean Tech right now for instant sheet metal fabrication quotes and some feedback on your DFM .

Let’s familiarize you with the metal stamping process to help you know it better. It has revolutionized modern-day metal product manufacturing. The process is simple yet very effective and benefits many industries. We’ll take you through the entire process, and you’ll visualize how it works. What is the scope globally? From 2014-2019 the metal stamping industry emerged [.]

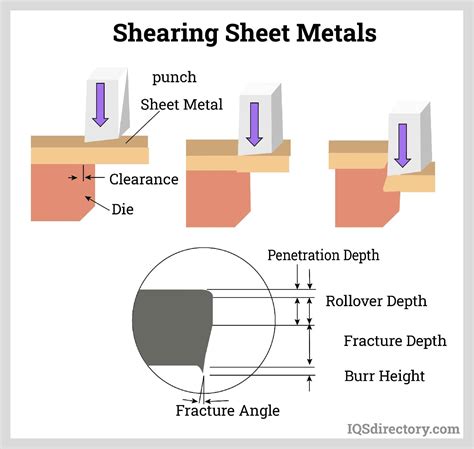

Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the processFinishing and Post-Processing After stamping, these professionals may apply additional post-processing steps, such as deburring (removing sharp edges), cleaning, surface treatment, and coating, to enhance the appearance, durability, and functionality of the stamped parts.. By following this systematic approach, the stamping process transforms raw metal sheets or coils . Find the perfect sheet metal quoting software to streamline your fabrication process. Our comprehensive guide covers the top solutions, features, and benefits to help you choose the best fit for your business. Get accurate quotes, optimize workflows, and . Blanking and fine blanking are both shear-cutting fabrication methods; they create sheet metal parts using die and punch tooling. One main difference between typical Sheet Metal Blanking and fine blanking processes is the clearance between the die and punch. Fine-blanked parts can easily achieve a tolerance of ±0.0003–0.002 inches.

Your strategic partner in metal stamping & sheet metal . An integrated production process through our ERP allow us to manage materials and machinery in a more efficient way, reflecting on the quality and competitiveness of our products and services. . (claims, quotes on time and projects on time) A metrology laboratory attended by experts .Our sheet metal fabrication factory strictly implements ISO 9001 quality management system. We have one 360-ton punch press, three 200-ton punch presses, and ten sets of 60-ton punch presses. 5. • Aluminum is also a popular metal used in sheet metal due to its flexibility, light weight, and cost effectiveness • Most common Grade 3003- H14 is fairly strong, while maintaining the same formability and low cost. It is corrosion resistant and weldable. It is often used in stampings, spun and drawn parts, and fan blades • Brass is an alloy of copper, which is widely . Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies.

During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. . Titanium stamping, like other forms of metal stamping, requires a die, a press, and a sheet or strip of metal.However, due to titanium’s unique properties, the stamping process needs careful calibration and controlled .New Hampshire Stamping Co., Inc.’s utilizes technologically advanced metal stamping systems and process controls to ensure we meet your quote, delivery, inventory and tracking needs every time. New Hampshire Stamping Co., Inc. has the engineering expertise, equipment and systems to make your unique design concept a successful operational reality.Sheet metal stamping is used to transform flat metal sheets into specific shapes in precison. Stamping of sheet metal is a process based on permanent deformation by cold forming to produce a variety of complex three-dimensional .

Whether you’re seeking precision metal stamping or wire EDM services, buyers must acquire the most accurate quotes for their parts. It’s equally important that the quote comes quickly, especially when deadlines call for quick turnarounds. At Century-Tywood, we value a smooth quoting process to get a project started on the right foot.

Boyang Hardware Factory is a professional manufacturer of Precision CNC Machining Parts, CNC Aluminum Parts, sheet metal stamping, plastic injection molding, Stamping process, CNC Machined Parts Service Supplier, Metals Die-cast, Injection Molding. Its products are exported to dozens of countries and regions.

What Is Sheet Metal Stamping? Sheet Metal Stamping Process. There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping. Forming .Continuous – Is a continuous stamping process where the stamping function continues until the press is shut down. Continuous Strip; Deep Drawn – Allows flat sheet metal to be turned into 3-D shapes. Die – Stamping Dies Development. Forming; Fully Sheared; Progressive Die – The raw stock is fed into a single die that has 2 or more .A sheet metal stamping process is a metalworking process carried out at room temperature wherein parts are both cut and shaped from a parent metal strip or coil by feeding them into several dedicated dies securely mounted on stamping presses that apply intense pressure.

Sheet metal fabrication and its intricate processes are always in my mind when I reflect on our experience at Shengen.Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force.A Snapshot of the Sheet Metal Stamping Parts Industry . Sheet metal stamping, an indispensable pillar of manufacturing, graces several industries, including automotive, aerospace, electronics, and more. The process involves pressing a sheet of metal into a die to create custom shapes, thereby playing a critical role in product manufacturing and .

Extrusion is a process in which a section of the deep drawn metal is pushed out to create a protrusion. This can be useful for creating certain functional features in a deep drawn box, or other types of deep draw stamping products.. 8. Hole Creation. Holes of various sizes and shapes can be created in deep drawn stampings as per the design requirements. . This step is critical in .Introduction to the sheet metal/ metal stamping industry BWC identified sheet metal and metal stamping employers among the top 10 workers’ compen-sation classifications with the highest fre-quency of claims and highest claims costs in Ohio. According to the National Council on Compensa-tion Insurance’s (NCCI’s) manual classifications,Andea's custom sheet metal fabrication services are a cost-effective, on-demand solution to your manufacturing needs. Our fabrication services range from low-volume prototype to high-volume production runs. You can submit your 2D or 3D drawings to get instant quotes directly.

sheet metal self drilling screws

sheet metal screw with washer

Watts Welding Shop, LLC has been a premier provider of metalworking services for over 40 years. We help all types of businesses with metalworking, welding and fabrication.

sheet metal stamping process quotes|sheet metal stamping steps