custom laser cutting sheet metal stamping Laser cutting and metal stamping are the two methods commonly associated with sheet metal fabrication. Laser cutting is more suited to smaller batches of customized parts. While stamping excels at large-volume factory .

The universal metal bracket, or L-shaped bracket, can be attached to a flat surface with both adhesive pads and/or screws. Quick and easy installation, along with substantial compatibilities, make this accessory a standout amongst the ecoprintQ hardware accessory line.

0 · standard sheet metal cutting service

1 · sheet metal laser cutting service

2 · laser cutting stainless steel parts

3 · custom sheet metal cutting service

Assuming that you only need to add records to the junction table from this form, build a form bound to the junction table. If you use the wizard, your new form should list each field as a textbox. For each field that is a foreign key, change the textbox to a combobox.

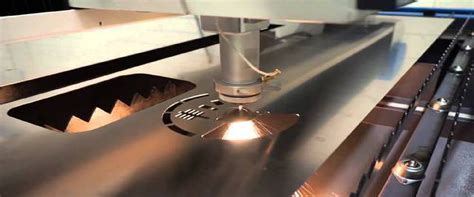

Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and .

Custom steel laser cutting is a specialized process designed for precision cutting of steel materials. This type of laser cutting is ideal for creating complex shapes and high-tolerance .

Customize a part template using our Parts Builder, or send a sketch to our Design Services team. Prices start from less than . Free shipping in the USA, from to Canada. Standard laser .As an ISO-certified supplier, we offer custom metal stamping, laser cutting, welding and press brake services. Why do customers rely on Dyco? Advanced Technology: In 2023, we completed our sixth expansion with the addition of .There are many ways to create custom sheet metal forms, two of the most popular methods using either metal stamping or laser cutting machines. These machines are used to create custom metal products for all sorts of purposes.

Laser cutting and metal stamping are the two methods commonly associated with sheet metal fabrication. Laser cutting is more suited to smaller batches of customized parts. While stamping excels at large-volume factory .AMFAS provides a wide range of custom sheet metal parts. We offer sheet metal fabrication services that include cnc laser cutting, bending and forming, single and multi-stage stamping, and deep-drawn parts. We also provide sheet metal . There are several methods for creating custom sheet metal forms, with metal stamping and laser cutting being two of the most prevalent. When determining which method is best for your project, it’s important to understand .Quick-Way Manufacturing is a precision ISO-9001:2015 Certified custom contract manufacturer specializing in laser cutting, precision sheet metal fabrication, and metal stamping across a wide range of applications.

standard sheet metal cutting service

Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and intricate cuts. . Custom Artwork; Architectural Elements; . Sheet Metal Stamping; Surface Finishing; Contact Us. Address::No. 3 Chongming Road, Shichong .Custom steel laser cutting is a specialized process designed for precision cutting of steel materials. This type of laser cutting is ideal for creating complex shapes and high-tolerance parts in steel.Customize a part template using our Parts Builder, or send a sketch to our Design Services team. Prices start from less than . Free shipping in the USA, from to Canada. Standard laser cutting orders are out the door in 2-4 days. Expect 1-3 day shipping anywhere in the USA. Upload a CAD file, send us a sketch, or use one of our templates.

sheet metal laser cutting service

Laser cutting is highly accurate and yields excellent cut quality with minimal heat affected zones. This process is ideal for fast, high-quality prototyping and low volume production quantities. Cutting SpecificationsAs an ISO-certified supplier, we offer custom metal stamping, laser cutting, welding and press brake services. Why do customers rely on Dyco? Advanced Technology: In 2023, we completed our sixth expansion with the addition of two 20kw fiber lasers with full automation.

There are many ways to create custom sheet metal forms, two of the most popular methods using either metal stamping or laser cutting machines. These machines are used to create custom metal products for all sorts of purposes. Laser cutting and metal stamping are the two methods commonly associated with sheet metal fabrication. Laser cutting is more suited to smaller batches of customized parts. While stamping excels at large-volume factory productions.

AMFAS provides a wide range of custom sheet metal parts. We offer sheet metal fabrication services that include cnc laser cutting, bending and forming, single and multi-stage stamping, and deep-drawn parts. We also provide sheet metal weldments and assemblies. There are several methods for creating custom sheet metal forms, with metal stamping and laser cutting being two of the most prevalent. When determining which method is best for your project, it’s important to understand the differences between each technique. 5-axis laser cutting and metal stamping processes each offer their own unique .Quick-Way Manufacturing is a precision ISO-9001:2015 Certified custom contract manufacturer specializing in laser cutting, precision sheet metal fabrication, and metal stamping across a wide range of applications.

Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and intricate cuts. . Custom Artwork; Architectural Elements; . Sheet Metal Stamping; Surface Finishing; Contact Us. Address::No. 3 Chongming Road, Shichong .Custom steel laser cutting is a specialized process designed for precision cutting of steel materials. This type of laser cutting is ideal for creating complex shapes and high-tolerance parts in steel.Customize a part template using our Parts Builder, or send a sketch to our Design Services team. Prices start from less than . Free shipping in the USA, from to Canada. Standard laser cutting orders are out the door in 2-4 days. Expect 1-3 day shipping anywhere in the USA. Upload a CAD file, send us a sketch, or use one of our templates.

Laser cutting is highly accurate and yields excellent cut quality with minimal heat affected zones. This process is ideal for fast, high-quality prototyping and low volume production quantities. Cutting SpecificationsAs an ISO-certified supplier, we offer custom metal stamping, laser cutting, welding and press brake services. Why do customers rely on Dyco? Advanced Technology: In 2023, we completed our sixth expansion with the addition of two 20kw fiber lasers with full automation.There are many ways to create custom sheet metal forms, two of the most popular methods using either metal stamping or laser cutting machines. These machines are used to create custom metal products for all sorts of purposes.

1997 f150 power distribution box

Laser cutting and metal stamping are the two methods commonly associated with sheet metal fabrication. Laser cutting is more suited to smaller batches of customized parts. While stamping excels at large-volume factory productions.

AMFAS provides a wide range of custom sheet metal parts. We offer sheet metal fabrication services that include cnc laser cutting, bending and forming, single and multi-stage stamping, and deep-drawn parts. We also provide sheet metal weldments and assemblies.

laser cutting stainless steel parts

We specialize in fabrication services of all metals and thicknesses. Listed below are just some of the things we can do. If the service you are looking for is not listed below or if you have any .

custom laser cutting sheet metal stamping|standard sheet metal cutting service