clinching tool for sheet metal joining Tog-L-Loc Clinching; Clinch Tooling; Clinching Equipment; . 100,000 styles, . A box junction is a traffic control measure marked by criss-crossed yellow lines at busy intersections. They are designed to prevent gridlock and keep traffic flowing smoothly. These yellow boxes with hatchings create an area that .

0 · tox clinching

1 · sheet metal joining machine

2 · sheet metal clinching parts

3 · metal clinching machine

4 · clinching sheet metal

5 · clinching machine

6 · btm tools

7 · btm clinching

An electrical box, also known as a junction box, is an essential component in electrical installations. It serves as a protective enclosure for electrical connections, ensuring safety and preventing damage to the wiring system.

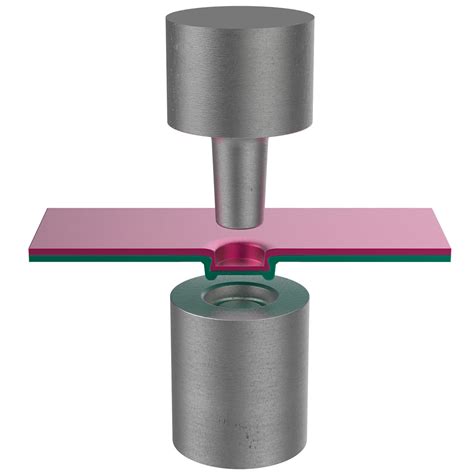

Clinching joins sheet metal by drawing and forming the part materials into an interlock. Using the part material improves production time and cost while eliminating welding and fasteners. It is an environmentally-friendly process – no sparks, fumes or heat.

Tog-L-Loc Clinching; Clinch Tooling; Clinching Equipment; . 100,000 styles, . TOX®-Clinching is a simple joining technique that does not require heat or additional elements.The Clinching process produces a button-type, positive connection of two or three layers of sheet metal using a cold-forming . TOX® sheet metal clinching tools join two or more layers of sheet metal to replace rivets and welds. Click here to view clinching our riveting tools today!

To meet customer demands for high-speed sheet metal joining, BTM offers a full line of Single Point Clinching Presses. To address customer applications that cannot be met with standard .

This 100% pneumatic tool is outstanding for joining large and thick sheet metal frames and profiles, such as ventilation ducts, door frames and much more, to a total thickness of 4.5 mm (construction steel).In clinching technology, clinching machines are ultra-fast, 100% pneumatic tools that can clinch two or more layers of sheet metal. The materials are plastically deformed inside a die through a squeezing process between the punch and .Clinching is a cold-forming process that allows sheet metal and other materials to be fastened together without the need for bolts, rivets, or adhesives.

Join metal parts in a cost effective and sustainable way with RIVCLINCH®. The most economical way to fasten sheet metal. With fast cycle times and unsurpassed consistency, production is increased. Clinching is energy saving, .TOX®-Clinching is a simple joining technique that does not require heat or additional elements. Learn more about our cost-effective joining equipment.

TOX® sheet metal clinching tools join two or more layers of sheet metal to replace rivets and welds. Click here to view clinching our riveting tools today!

Clinching is a cold-forming process that allows sheet metal and other materials to be fastened together without the need for bolts, rivets, or adhesives.It allows the joining of sheet metal parts made of steel, copper and aluminum with a thickness from 0.1 to 1.2 mm. The conductivity of sheet metal usually coated with tin, silver or conductive grease is preserved during the clinching process.Find the right clinching joint for your sheet metal joining application. The TOX® clinch procedure is a proven substitute for welding, screwing & riveting.The cold joining process TOX®-Clinching is a highly effective solution for this purpose. During clinching or press joining, the sheet metals to be joined are connec-ted force- and positive-locking with each other in a con-tinuous forming process. A wide range of materials can be joined with this press-forming process, all without

The TOX®-TWINpoint along with the TOX®-Round-Point initial joint and its variants, form a wide range of possibilities to join sheet metal. This new joint is a 2 in 1 solution – two joints formed from one stroke of the press, using one set of tools (punch and die).

tox clinching

We invented the "clinching" - the joining of sheet metal by force and we developed machine drives such as our pneumohydraulic power-packages - which offer forces from 2 - 2000 kN. We have solutions for pressing , riviting , inserting elements and much more.

Clinching is a cold-forming process that allows sheet metal and other materials to be fastened together without the need for bolts, rivets, or adhesives.Joining of sheet metals with non-metallic materials (e.g. plastics, elastomers, paper, cardboard). Simple joining of high strength materials. Increased tool life.TOX®-Clinching is a simple joining technique that does not require heat or additional elements. Learn more about our cost-effective joining equipment.

TOX® sheet metal clinching tools join two or more layers of sheet metal to replace rivets and welds. Click here to view clinching our riveting tools today!

Clinching is a cold-forming process that allows sheet metal and other materials to be fastened together without the need for bolts, rivets, or adhesives.It allows the joining of sheet metal parts made of steel, copper and aluminum with a thickness from 0.1 to 1.2 mm. The conductivity of sheet metal usually coated with tin, silver or conductive grease is preserved during the clinching process.Find the right clinching joint for your sheet metal joining application. The TOX® clinch procedure is a proven substitute for welding, screwing & riveting.The cold joining process TOX®-Clinching is a highly effective solution for this purpose. During clinching or press joining, the sheet metals to be joined are connec-ted force- and positive-locking with each other in a con-tinuous forming process. A wide range of materials can be joined with this press-forming process, all without

The TOX®-TWINpoint along with the TOX®-Round-Point initial joint and its variants, form a wide range of possibilities to join sheet metal. This new joint is a 2 in 1 solution – two joints formed from one stroke of the press, using one set of tools (punch and die).We invented the "clinching" - the joining of sheet metal by force and we developed machine drives such as our pneumohydraulic power-packages - which offer forces from 2 - 2000 kN. We have solutions for pressing , riviting , inserting elements and much more.Clinching is a cold-forming process that allows sheet metal and other materials to be fastened together without the need for bolts, rivets, or adhesives.

sheet metal joining machine

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process.

clinching tool for sheet metal joining|metal clinching machine