cnc ceramic milling machine In the CNC milling process for ceramics, a machine guided by computer commands employs a spinning cutting tool to shape a ceramic piece by removing material. This technique skillfully carves out the required form or design.

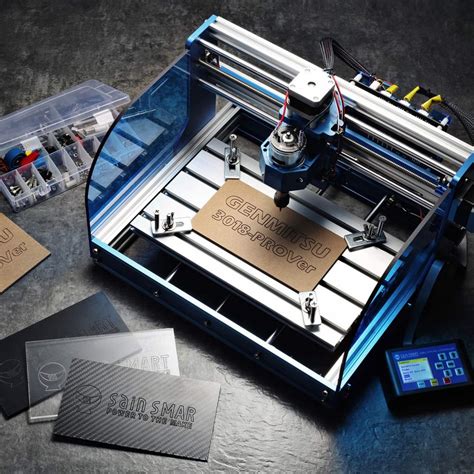

$299.88

0 · types of cnc milling machines

1 · most affordable cnc milling machines

2 · compact cnc milling machine

3 · cnc milling machine pdf

4 · cnc milling machine near me

5 · cnc milling machine description

6 · best milling machine for small shop

7 · affordable cnc milling machines

What does IP mean as in I/P Fuse Panel? I have voltage to the switch but it's not getting to the motor.

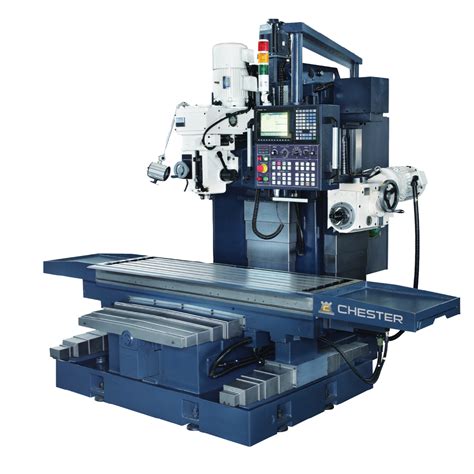

types of cnc milling machines

Ceramic CNC machining is a subtractive manufacturing process that uses CNC machine tools to remove material from a block of raw material to create a specific shape. Ceramic CNC machining uses advanced cutting tools . Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. .

most affordable cnc milling machines

Advanced ceramic CNC milling harnesses the power of a computer-controlled milling machine equipped with specialized diamond cutting tools. The CNC program meticulously guides the .

CNC machining is incredibly precise, perfect for making complex and detailed ceramic parts. It uses advanced machinery and software for excellent control over the cutting and shaping, resulting in high-quality, accurate components that .

In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it .

In the CNC milling process for ceramics, a machine guided by computer commands employs a spinning cutting tool to shape a ceramic piece by removing material. This technique skillfully carves out the required form or design.

CNC milling for ceramics is a process in which a computer-controlled machine uses a rotating cutting tool to remove material from a ceramic workpiece to create a desired shape or form. One of the key advantages of CNC milling for ceramics is the ability to produce complex shapes with high precision. Ceramic CNC machining is a subtractive manufacturing process that uses CNC machine tools to remove material from a block of raw material to create a specific shape. Ceramic CNC machining uses advanced cutting tools such as diamond, cubic boron nitride, and custom made tools to create high-precision components.

Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. Ceramics, known for their hardness and brittleness, require specialized machining processes to achieve the desired results.

compact cnc milling machine

Advanced ceramic CNC milling harnesses the power of a computer-controlled milling machine equipped with specialized diamond cutting tools. The CNC program meticulously guides the tool’s movement, removing material from the ceramic workpiece to achieve the desired shape and features. This process enables:CNC machining is incredibly precise, perfect for making complex and detailed ceramic parts. It uses advanced machinery and software for excellent control over the cutting and shaping, resulting in high-quality, accurate components that meet strict standards. In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it plays in industries that demand high-performance ceramic parts.Precision Ceramics has extensive experience with high-tolerance technical ceramic milling, grinding and polishing of unfired (‘green’) and fired ceramics. Our state-of-the-art equipment allows us to offer a variety of technical ceramic services including: CNC Milling & Grinding; Brazing & Joining; Glazing; Lapping & Polishing; Metalizing

CNC GANTRY MILLING MACHINE OVERHEAD - OUR FLEXIBLE SPACE-SAVING OPTION Gantry CNC Machine, available in four different sizes for different process .Ceramic CNC Machining is a precision manufacturing process that uses computer-controlled machines to shape ceramic materials like alumina and zirconia. These materials are selected for their durability and resistance, making them ideal for various applications.In the CNC milling process for ceramics, a machine guided by computer commands employs a spinning cutting tool to shape a ceramic piece by removing material. This technique skillfully carves out the required form or design.

CNC milling for ceramics is a process in which a computer-controlled machine uses a rotating cutting tool to remove material from a ceramic workpiece to create a desired shape or form. One of the key advantages of CNC milling for ceramics is the ability to produce complex shapes with high precision.

Ceramic CNC machining is a subtractive manufacturing process that uses CNC machine tools to remove material from a block of raw material to create a specific shape. Ceramic CNC machining uses advanced cutting tools such as diamond, cubic boron nitride, and custom made tools to create high-precision components.

Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. Ceramics, known for their hardness and brittleness, require specialized machining processes to achieve the desired results.Advanced ceramic CNC milling harnesses the power of a computer-controlled milling machine equipped with specialized diamond cutting tools. The CNC program meticulously guides the tool’s movement, removing material from the ceramic workpiece to achieve the desired shape and features. This process enables:CNC machining is incredibly precise, perfect for making complex and detailed ceramic parts. It uses advanced machinery and software for excellent control over the cutting and shaping, resulting in high-quality, accurate components that meet strict standards. In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it plays in industries that demand high-performance ceramic parts.

Precision Ceramics has extensive experience with high-tolerance technical ceramic milling, grinding and polishing of unfired (‘green’) and fired ceramics. Our state-of-the-art equipment allows us to offer a variety of technical ceramic services including: CNC Milling & Grinding; Brazing & Joining; Glazing; Lapping & Polishing; MetalizingCNC GANTRY MILLING MACHINE OVERHEAD - OUR FLEXIBLE SPACE-SAVING OPTION Gantry CNC Machine, available in four different sizes for different process .

eason metal fabrication

cnc milling machine pdf

cnc milling machine near me

cnc milling machine description

Learn the crucial differences between fabrication and welding in metalworking. Discover how each process works, the skills required, and when to use each for your project.

cnc ceramic milling machine|cnc milling machine pdf