cnc machine monitoring adapter Using the data collected from your CNC control panel, via our Integrated Machine Analytic (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real-time.

$20.09

0 · Predator MDC CNC Data Collection

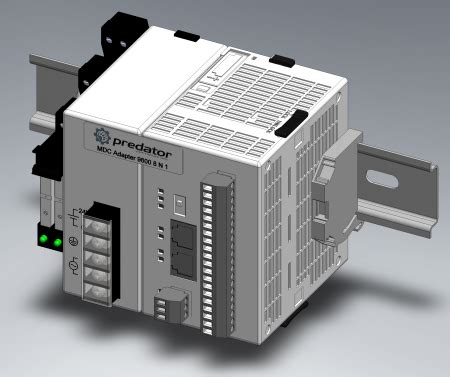

1 · Predator MDC Adapter for hardware based machine monitoring

2 · Machine Monitoring System

3 · MTConnect CNC Machine Monitoring with Predator

4 · IMA Adapter

5 · IIoT Solutions

6 · Collect Data from Mazak CNC with MTConnect

7 · Chatter

8 · CNC Monitoring

9 · CNC Machine Monitoring Software

$950.00

Using the data collected from your CNC control, via our Integrated Machine Analytics (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real time.Leverage the power of Predator MDC with MTConnect to simplify machine monitoring and manufacturing data collection via Ethernet. Track cycle time, setup time and teardown time; Collect downtimes, idle time and part counts; .

Hardware-based data collection for older CNCs, manual machines and other equipment are supported. Predator MDC Adapters are din rail mounted and are wired into signal lamps, light .Mazak SMOOTH Link is an on-premise proprietary machine monitoring solution designed specifically for MAZATROL Smooth CNCs. SMOOTH Link is capable of syncing real-time machine data to mobile devices over Wi-Fi. Users can use .Enjoy automatic, error-free, & unattended machine monitoring for events such as job start/end, setup start/end, log on/off, cycle start/end, & more. Real-time production monitoring data collected includes cycle time, idle time, setup time, .

Using the data collected from your CNC control panel, via our Integrated Machine Analytic (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real-time.MTConnect adapter and agent must be installed for successful collection of data from CNC machine. Data such as Machine State, Feedrate Override, and more. An Edge device is use to collect data via MTConnect communication protocol.

Chatter is a cloud-based platform that helps machine shops visualize their data in realtime, with a simple 5-minute setup.

Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.Predator MDC Adapters are an affordable solution for hardware based machine monitoring and data collection. Predator MDC Adapters support a wide range of CNC machines, robots, PLCs, test stands and other shop floor equipment.Using the data collected from your CNC control, via our Integrated Machine Analytics (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real time.

Leverage the power of Predator MDC with MTConnect to simplify machine monitoring and manufacturing data collection via Ethernet. Track cycle time, setup time and teardown time; Collect downtimes, idle time and part counts; Analyze metrics per job, part, operation, shift, user, cell and more; Works with any MTConnect enabled CNC, CMM or sensor

Hardware-based data collection for older CNCs, manual machines and other equipment are supported. Predator MDC Adapters are din rail mounted and are wired into signal lamps, light towers, extended M functions or any digital input or output.Mazak SMOOTH Link is an on-premise proprietary machine monitoring solution designed specifically for MAZATROL Smooth CNCs. SMOOTH Link is capable of syncing real-time machine data to mobile devices over Wi-Fi. Users can use the solution for monitoring production status, tool management, and programming.Enjoy automatic, error-free, & unattended machine monitoring for events such as job start/end, setup start/end, log on/off, cycle start/end, & more. Real-time production monitoring data collected includes cycle time, idle time, setup time, teardown time, machine downtime, & scrap reasons.Using the data collected from your CNC control panel, via our Integrated Machine Analytic (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real-time.

MTConnect adapter and agent must be installed for successful collection of data from CNC machine. Data such as Machine State, Feedrate Override, and more. An Edge device is use to collect data via MTConnect communication protocol.

Chatter is a cloud-based platform that helps machine shops visualize their data in realtime, with a simple 5-minute setup.Predator MDC is real-time machine monitoring software that automatically collects, reports, charts and processes real-time shop floor manufacturing data including OEE, cycle time, idle time, setup time, teardown time, machine downtime and more.Predator MDC Adapters are an affordable solution for hardware based machine monitoring and data collection. Predator MDC Adapters support a wide range of CNC machines, robots, PLCs, test stands and other shop floor equipment.

Using the data collected from your CNC control, via our Integrated Machine Analytics (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real time.

Leverage the power of Predator MDC with MTConnect to simplify machine monitoring and manufacturing data collection via Ethernet. Track cycle time, setup time and teardown time; Collect downtimes, idle time and part counts; Analyze metrics per job, part, operation, shift, user, cell and more; Works with any MTConnect enabled CNC, CMM or sensor

Hardware-based data collection for older CNCs, manual machines and other equipment are supported. Predator MDC Adapters are din rail mounted and are wired into signal lamps, light towers, extended M functions or any digital input or output.Mazak SMOOTH Link is an on-premise proprietary machine monitoring solution designed specifically for MAZATROL Smooth CNCs. SMOOTH Link is capable of syncing real-time machine data to mobile devices over Wi-Fi. Users can use the solution for monitoring production status, tool management, and programming.Enjoy automatic, error-free, & unattended machine monitoring for events such as job start/end, setup start/end, log on/off, cycle start/end, & more. Real-time production monitoring data collected includes cycle time, idle time, setup time, teardown time, machine downtime, & scrap reasons.

Using the data collected from your CNC control panel, via our Integrated Machine Analytic (IMA) adapter, allows you to actively monitor, as well as analyze, your production floor in real-time.MTConnect adapter and agent must be installed for successful collection of data from CNC machine. Data such as Machine State, Feedrate Override, and more. An Edge device is use to collect data via MTConnect communication protocol.

Predator MDC CNC Data Collection

kaufman essex yarn dyed metallic linen blend rose fabric

kaiser aluminum fabricated products llc ca phone

Check out our vintage cigarettes tin box selection for the very best in unique or custom, handmade pieces from our tobacciana shops.

cnc machine monitoring adapter|Predator MDC Adapter for hardware based machine monitoring