battery junction box electric vehicle Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and . CANTEX LEZ55QNB EZ BOX is a 55 cu. in. 4-gang nail-on electrical switch and outlet box for residential or light commercial new construction (new work) electrical installations. It features .

0 · intelligent battery junction box

1 · high voltage battery box

2 · ev junction box design

3 · ev battery junction box

4 · electric vehicle junction box

5 · electric battery junction box

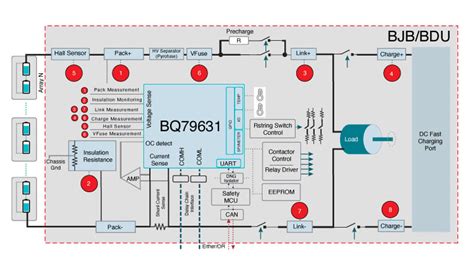

6 · battery junction box diagram

7 · battery junction box architecture

Waterproof your outdoor splices with the DryConn medium, aqua/red wire connector. This quality one-step connector is filled with a dielectric silicone sealant that surrounds splices, making it water and corrosion resistant.

ground wires are in electrical box capped

As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities. .How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems Issac Hsu As electric vehicles (EVs) become more popular, the challenge for automakers is to .

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and .How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and . The MC33777 battery junction box IC is the latest addition to NXP’s Electrification system solution portfolio to manage the flow of energy in EVs with flexibility and precision to . A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.

grip steel box

Learn how a capacitive-isolation daisy-chain data acquisition IC enables a streamlined EV junction box, eliminating multiple components. Electric vehicles (EVs) are powered by huge battery banks (Fig. 1), constructed of long .How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems The new NXP MC33777 is the world’s first battery junction box integrated circuit (IC) to integrate sense, think and act capabilities on a single device. Compared to previous generations, it redefines battery management . NXP recently rolled out a battery junction box IC that combines critical pack-level monitoring functions in a single chip. According to the company, it delivers faster, safer, and .

As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities. Every single watt-hour stored and retrieved from the cells is critical to extending the driving range.How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems Issac Hsu As electric vehicles (EVs) become more popular, the challenge for automakers is to reflect true range while making the vehicle more affordable. This translates into making the battery packs lower cost with higher energy densities.

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements.How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery. The MC33777 battery junction box IC is the latest addition to NXP’s Electrification system solution portfolio to manage the flow of energy in EVs with flexibility and precision to extend driving range while maintaining vehicle safety. A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.

Learn how a capacitive-isolation daisy-chain data acquisition IC enables a streamlined EV junction box, eliminating multiple components. Electric vehicles (EVs) are powered by huge battery banks (Fig. 1), constructed of long strings of batteries in series that can achieve operating voltages higher than 800 V and an average current of 40 A.How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems

The new NXP MC33777 is the world’s first battery junction box integrated circuit (IC) to integrate sense, think and act capabilities on a single device. Compared to previous generations, it redefines battery management systems with its unparalleled performance and safety for high-voltage applications.

NXP recently rolled out a battery junction box IC that combines critical pack-level monitoring functions in a single chip. According to the company, it delivers faster, safer, and more. As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities. Every single watt-hour stored and retrieved from the cells is critical to extending the driving range.How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems Issac Hsu As electric vehicles (EVs) become more popular, the challenge for automakers is to reflect true range while making the vehicle more affordable. This translates into making the battery packs lower cost with higher energy densities. Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements.

How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery. The MC33777 battery junction box IC is the latest addition to NXP’s Electrification system solution portfolio to manage the flow of energy in EVs with flexibility and precision to extend driving range while maintaining vehicle safety. A traditional battery junction box is a relay box or switch box with a power contactor that connects the entire battery pack to a load inverter, motor, or battery charger. Figure 1a shows a traditional BMS.

Learn how a capacitive-isolation daisy-chain data acquisition IC enables a streamlined EV junction box, eliminating multiple components. Electric vehicles (EVs) are powered by huge battery banks (Fig. 1), constructed of long strings of batteries in series that can achieve operating voltages higher than 800 V and an average current of 40 A.How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems

The new NXP MC33777 is the world’s first battery junction box integrated circuit (IC) to integrate sense, think and act capabilities on a single device. Compared to previous generations, it redefines battery management systems with its unparalleled performance and safety for high-voltage applications.

intelligent battery junction box

high voltage battery box

ev junction box design

Classic wavy corrugated panel - 1/2" high ribs. 2.5″ Corrugated is our medium height corrugated sheet – and our most popular. With the strength needed to excel on both roof and wall applications, 2.5″ Corrugated takes on coastal, rugged, and contemporary applications with ease.

battery junction box electric vehicle|battery junction box diagram