surface finish sheet metal Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and final coating to achieve specific . This article overviews outdoor light junction boxes and details the many junction boxes available. By understanding more about outdoor light junction boxes, you can choose the right type for your needs and ensure that your outdoor lighting system functions properly.

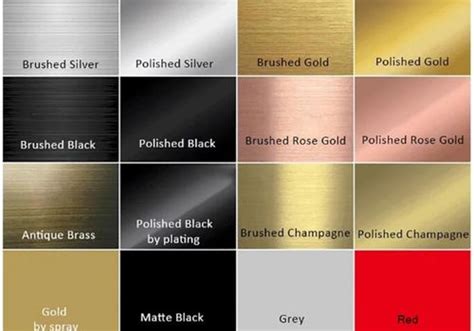

0 · types of metal surface finishes

1 · types of metal finish chart

2 · milling surface finish chart

3 · metal surface finishing techniques

4 · metal surface finishes chart

5 · measuring surface finish on metal

6 · material surface finish chart

7 · different types of surface finishes

$9.99

Surface finish is an essential consideration for many sheet metal fabrication projects—including, most commonly, parts requiring beautiful . Class C, also known as a "mill finish," is the default finish at most sheet metal fabrication shops. It has some surface imperfections, such as .

best classic mustang sheet metal

Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and final coating to achieve specific . Surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. These finishes range from dull to bright and include special textures that may . A metal surface finish refers to the specific treatment or coating applied to the exterior surface of a metal workpiece. This treatment is intended to enhance the properties of the metal, which can include improving its .

Metal surface treatment allows you to enhance your product’s appearance, performance and lifespan. The Komacut platform simplifies obtaining sheet metal parts with your preferred surface finishing at mass production quality and pricing by offering a range of standard metal surface treatments, in a variety of colors and finishes.Simply upload your drawings to receive instant .

best cam software for cnc machining

Sheet metal finishing enhances both the appearance and functionality of metal parts. The right finish prevents rust, increases wear resistance and creates an attractive surface texture. Modern finishing techniques like powder coating, anodizing, and plating deliver reliable protection while meeting precise aesthetic requirements.Sheet metal finishing enhances both the appearance and functionality of metal parts. The right finish prevents rust, increases wear resistance and creates an attractive surface texture. Modern finishing techniques like powder coating, anodizing, and plating deliver reliable protection while meeting precise aesthetic requirements. Our sheet metal finishes vary in design but shall be used to achieve different visual effects and applications. The finishes deliver additional value due to improved appearance, corrosion resistance, and longevity. There are, however, differences in properties functionality, and finishing costs so it is essential to understand your specific needs for surface finish of .There are many combinations of Steel Plate and Sheet types and finishes. From types such as A36 or 516-70 to finishes from hot rolled to cold rolled. . Cold rolled steel is made to much tighter dimensional tolerances and the surface is more uniform .

best cam software for cnc machining

Line graining, or linear graining, is the process of adding a uniform surface finish to sheet metal parts. This is done by running the metal through a belt grinder. Applications for Linear Graining. Line graining adds a directional pattern and grained finish to steel or aluminum parts. Graining removes factory defects such as scratches, mill .

The sustained impact of these tiny beads on the metal’s surface creates smooth sheet metal surface finishes with matte textures. Bead blasting is a fairly standard sheet metal finishing process. However, it is also ideal for cleaning or removing paint from finished parts. The visual quality of bead-blasted metal parts makes the post process a . Surface finish refers to the process of altering a metal’s surface that involves removing, adding, or reshaping. It is a measure of the complete texture of a product’s surface that is defined by three characteristics of surface roughness, waviness, and lay. . Surface Roughness Chart Cheat Sheet. This surface finish ‘cheat sheet’ is a . Surface Roughness. Surface roughness is a critical aspect of sheet metal finishing, influencing both the aesthetics and functional properties of the final product. Different finishing methods yield varying degrees of surface roughness, and understanding this aspect is crucial to ensure that the finished product aligns with the specified . Understanding the Role of Metal Type. Different types of metals‘ physical and chemical properties are distinct and affect the different finishing operations in varying degrees of effectiveness. For instance, steel, the most common ferrous metal, usually goes through galvanizing in order to prevent screen damage since it rusts very quickly owing to its iron .

Finishing of sheet metal parts. There are several finishing techniques to get the perfect sheet metal finish that meets your needs. There is a wide range of finishes for stainless steels, such as the common 2D finish or a 2BA (Bright Annealed) finish that is made by brushes or a no. 5 with a Scotch-Brite belt. The deburring machines can be equipped with a Scotch-Brite belt, to add a .

Applications of Number 3 Finish: Stainless steel sheet metal with a Number 3 finish sets itself apart because it has a pattern pressed into a surface that gives it a look of scratching and abrasion. Additionally, it is fairly bright, offering a modest reflection.

Sheet Metal. Sheet Metal Laser Cutting . Metal Bending Metal Benching Metal Welding. More. More Metal Casting. EDM Machining Metal Etching Rapid Tooling. Solutions. Solutions Rapid Prototyping. Low Volume Production Surface Finishing. . How does surface finish impact the functionality of a component?Stainless Steel 2B Finish: Pros and cons Pros. Enhances aesthetic appeal: The smooth, reflective surface is ideal for decorative and functional uses. Corrosion Resistant: A high chromium content provides excellent resistance to chemicals and moisture. Durability: Resists wear, providing long-lasting performance.; Easy To Clean: The smooth surface is ideal for food processing or .

types of metal surface finishes

types of metal finish chart

There are various sheet metal surface finishes that are available off the shelf, including brushed and treated variants. Raw. Visible tooling marks and light surface scratches. Raw Copper C101. Visible tooling marks and light surface . Before choosing any sheet metal finishing, you need the right information. This guide discusses some of the top 11 finishing operations for sheet metal fabrication. So, before choosing any of the available options, read this .

Listed below are some of the more common finishing processes specifically used on sheet metal parts. Many of these surface finishes offer improved corrosion resistance. Corrosion resistance is a general term, .

milling surface finish chart

Finish for close tolerances. Unless otherwise agreed the surface roughness shall be Ra ≤ 1,2. 2P: Smoother and brighter than finish 2B or 2G. Free of surface defects. Finishes 2H, 2D, 2B or 2G, specular polishing: Products showing a well groomed surface appearance. Surface roughness shall be specified at the time of enquiry and order.Buy SOFIALXC 304 Stainless Steel Sheet,mirror Surface Polishing Finish, Metal raw Materials-200X300MM Thick:0.6mm: Sheets - Amazon.com FREE DELIVERY possible on eligible purchases Amazon.com: SOFIALXC 304 Stainless Steel Sheet,mirror Surface Polishing Finish, Metal raw Materials-200X300MM Thick:0.6mm : Industrial & Scientific You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, EDM, and surface grinding, as well as milling, turning, lapping, and polishing. . Surface Finish Cheat Sheet. Micrometers Rating Microinches Rating Applications 25 100:

Q: What types of surface finish are used for sheet metal surfaces? A: Types of surface finish used for sheet metal surfaces include hot-dip galvanizing, electroplating, anodizing, powder coating, and painting. Each finish used will depend on factors such as desired appearance, corrosion resistance, and application requirements.

Guide to Stainless Steel Sheet Finishes | Magnetic, Non-Magnetic, Mill, Polished, Brushed, Mirror. . An intermediate polished surface obtained by finishing with a 120-grit abrasive. A directional course "grain" running in one direction. . Online Metal Supply 1035 Melflowers Drive Houston, MO 65483; Call us at 417-967-8291; Navigate.When working in metal finishing industries, you have most certainly heard about surface roughness. It measures the irregularities on the surface and is one of the characteristics of the surface texture, besides lay and waviness. The friction and wear of sheet metal is depending on the surface texture, thus is it important to examine.

Polishing is a typical mechanical finishing process involving chemical agents or abrasives to create a high-gloss, mirror-like finish on the surface of metal parts. This finishing process enhances the physical properties of metal machined parts, increases corrosion resistance, improves cleanliness, and mitigates friction. Different processing methods and cold rolling after processing, stainless steel surface can have different levels of surface finish, grain and color. The surface processing of cold-rolled stainless steel plate has 2D, 2B, No.3, No.4, 240, 320, No.7, No.8, HL, BA, TR hard state, embossed surface grade. The exemplary sheet metal surface finish is crucial because it determines the part’s performance, durability, and longevity. For example, components likely to undergo mechanical stress require a tough surface coating. In contrast, those who are likely to be exposed to the elements require protection from the environment. The finish is as .

The metal that comes with the thinnest oxidation coating after rolling is by far sheet metal. The resulting mill finish of bars of raw metal depends on a variety of factors. Besides the subtle differences between the mill finish of metal bars produced by several mills, there are slight differences between each stock produced in the same batch .

best cnc lathe turning parts quotes

best cnc engraving machine center quotes

Rivets are one of the vital tools that enable these component assemblies. However, these types of rivets often have varying design requirements, materials, applications, and properties. This article is a .

surface finish sheet metal|measuring surface finish on metal