hemming tool for sheet metal The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem. What are the material limitations for closed hems? Closed hems work best .

The answer is that the diameter of the hole decreases as the outer and inner circumference of the steel expand in opposite directions. On the other hand, if a circle is drawn .

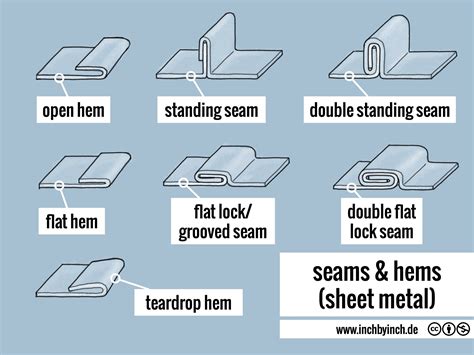

0 · types of sheet metal seams

1 · sheet metal hand hemming tool

2 · sheet metal edge finishing tool

3 · seaming process in sheet metal

4 · seam joint in sheet metal

5 · hemming process in sheet metal

6 · hemmed edge sheet metal

7 · difference between hemming and seaming

Shop NASCAR merchandise, diecasts, and racing apparel from the Hendrick Motorsports team.

WILA offers a range of hemming tools for different material thicknesses and bending needs. Hemming can eliminate sharp edges, improve aesthetics and .Learn what sheet metal hemming is, how it is done with dies or rollers, and what are the different hem shapes and benefits. Also, find out how hemming differs fro.

Tools Required. Effective hemming relies on specialized tools: Sheet Metal: Thin, malleable metal sheets made from aluminum, steel, or copper. Hemming Tools or Press . The hemming tool or press brake bends the metal sheet’s edge at a 90º angle and folds the initially bent edge back onto the metal sheet to form a hem. After, clutch the hem to ensure a secure and firm fit.A sheet metal hem’s primary purpose is to create a smooth, rounded, or folded edge on a piece of sheet metal. The rounded edges make the sheet metal safer to handle. They also enhance the aesthetic appeal. Hemming also adds . The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem. What are the material limitations for closed hems? Closed hems work best .

Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in . Place the sheet metal in the hemming tool, assembling the edge that needs hemming with the hemming tool. 3. Hemming Procedure. The hemming tool or press brake bends the metal sheet’s edge at a 90º angle and .Sheet metal tools for roofing: Seamers, Snips, Benders, Gutter Clamps, Hand Tongs, Standing Seam Tools, and Tinners Hammers. Great service, quick shipping! 888.847.3456

Common Uses of Hemming Tools in Sheet Metal Fabrication. Hemming tools find applications in numerous industries where sheet metal fabrication is required. Here are some common uses: 1. Automotive Industry: . A Hemming Tool with Added Grip. The hemming tools from Mate come with a knurled, or textured, edge. This helps grip the sheet metal so operators don’t have to use their body weight to fight and hold the sheet metal in place. Sometimes the knurled edge leaves unwanted markings on the sheet metal. Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with 700N/mm 2 tensile strength (stainless steel); There are four primary hemming bending solutions designed to accommodate various bending .

types of sheet metal seams

At Approved Sheet Metal, we rely on our advanced press brake for all custom sheet metal hemming. Here’s a look at the four most common types of sheet metal hems that we use: Table of Contents. 1; 2 When to apply the 4 Common Types of Sheet Metal Hems to your Design. 2.0.1 1. Closed hem. 2.0.2 2. Teardrop hem. 2.0.3 3. Open hem.AJC Tools AJC Sheet Metal Folding & Hemming Tool (11.25 Inches) 3.9 out of 5 stars. 8. .00 $ 56. 00. FREE delivery Mon, Nov 25 . Only 20 left in stock - order soon. Add to cart-Remove. Hand Seamer, 6in Straight Jaw Sheet Metal Bender Tools, Sheet Metal Seamer Form Edge Seamer Seaming Plier with Ergonomic Handle, for Bending and Flattening .

Hemming increases the strength of thin components. This technology also offers the following advantages: You can join a wide range of materials – from aluminum and steel right through to plastics; You achieve shorter cycle times: The motion of the flange-mounted hemming roller is closely synchronized with the robot motion over the component.As a result, it is possible to cut .

If you are looking for a professional sheet metal machinery and bending tools supplier for custom application, JSTMT is your best choice. Add : No 324, Gulou Road, Lane 1198, Shanghai, China

Depending on the material and your tool set-up, you can hem sheet metal up to 4mm thick. Check out our product specifications or contact WILA for advice. What is the shortest hem I can make? The first step when creating a hem is to make a 30° bend. The shortest hem you can make depends on the minimum flange length you can bend in this step.

Versatile, compact 18-inch (46 cm) drip edge folding tool makes quick bends along the drip edge of flat-pan standing seam metal roofing panels.Two rib-reinforced steel plates are permanently welded together to create two folding seams for making 1-inch (25.4 mm) and 1-1/2-inch (38.1 mm) deep bends in maximum 22-gauge (0.76 mm) steel.Flattening tools Hemming, or flattening, is a great way to finish sharp edges or strengthen parts when bending sheet metal. Our spring-action and hydraulic flattening tools can be customized to fit your needs. Tailor-made flattening tools. Finding the right flattening tool for your operation depends on a number of factors. . The final hemming completely flattens the sheet and completes the hem shape using a different part of the same sheet metal hem tool. This process is mostly used for producing flat, simple panels and is not flexible when it comes to handling complex shapes. Although the initial investment in die-hemming equipment is high, it offers low cycle .

COHEALI 20 Pcs Stainless Steel Hemming Clips Marker Quilting Supplies for Sewing Machine Accessories Magnet Tape Magnet Tool Metal Hemming Clips 3 Inches Sewing Clips Adhesive Tape Ruler. .29 $ 10. 29. FREE delivery Oct 3 - 24 . . Malco 18F Sheet Metal 18" Folding Tool (1per Pack) , Silver. 4.8 out of 5 stars. 196. Hemming is a crucial process in sheet metal fabrication that involves bending and folding the edge of a sheet metal onto itself to achieve several key. Products Product Category PRESS BRAKE TOOLINGS PANEL BENDING TOOLS SHEAR BLADES . Hemming Tools for Sheet Metal Fabrication .The Best Metal Bending Tool for Standing Seam Roofing. The Eave and Valley Hemmer is a metal bending tool that allows roofers to bend sheet metal roofing panels for standing seam roofing jobs without the use of hand tools like pliers .

Below are the primary steps to hem sheet metal: Prepare Tools and Materials: First, choose appropriate sheet metal materials and tools, such as hammer, brake, or specialized metal folding tools. Marking and Cutting: Mark the edges on the sheet metal and use cutting tools to precisely cut along the marked lines. If needed, it can use a folding .This ingenious metal bending hemming tool allows roofers to bend sheet metal roofing panels for standing seam roofing jobs without the need for pliers, snips, hand seamers or other hand tools. Unlike other sheet metal bending tools, the Eave and Valley Hemmer helps you create perfect lines consistently with on your hips, eaves and valleys. And . Cons of Sheet Metal Hemming. Let’s discuss the disadvantages of the sheet metal hemming process; Time Taking Process; Sheet metal hemming is generally time-consuming, particularly for complex metal pieces. The right tool setup is necessary for hemming, which can take time. Skilled Personnel Required; Hemming well usually requires skilled workers.

There are various methods for producing sheet metal flattening ; The hemming process will be done in two steps: acute-angled is bend; . Hemming tool Light Weight Hemming II 1136. More Information: Double deck die: V6: 125.00 mm: 500 kN/m: SPECIAL: Hemming tool 622. More Information: Punch: V0: 65.00 mm:Tools and Equipment For Sheet Metal Hem The Necessary Sheet Metal Hemming Tools. We at Shengen understand the importance of having the correct tools and equipment to perform flawless sheet metal hemming. The tools in our workshop are all important to the process. We are proud of our investment in top-quality equipment that allows us to deliver .Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. All of Wilson Tool’s product lines offer a solution to make the 30° bend and hem all in one handling. If necessary, a special tool set can create a gapped hem, in which the hem is not fully flattened against the sheet, but leaves space between them.

The double disc hemming tool, by Perfect Benders, will take metal from 90° to 180°. Useful for panels longer than a brake.https://www.stortz.com/product/rol.Hemming is used in the sheet metal forming industry. There are two types of hemming operations: conventional die hemming and roll hemming. . Normally the actual hemming is a result of a forming operation in which the flange is formed with a hemming tool after the drawing and trimming operations have been completed. The formed flange is then .

Trick Tools offers sheet metal hand tools that can shear, brake, and notch sheet metal. Angle Finders & Levels Angle Finders Levels Bend Protractors Tube Rotation Gauges . HEM Saw; Hougen; Huth; Hyd-Mech; Hypertherm; Icengineworks; Inventive Products; Irwin; Jamey Jordan; Jancy Engineering; JET; JMR Manufacturing; JS Tools; Kalamazoo .AJC Sheet Metal Folding & Hemming Tool (11.25 Inches) 3.9 out of 5 stars. 8. .00 $ 56. 00. FREE delivery Wed, Mar 27 . 18 Inch Metal Bender Hand Tool,Sheet Metal Folding Tool for Duct Bending,Metal Bending Tools,Yellow. 5.0 out of 5 stars. 11. 50+ bought in .

Our hemming tools will save you and your customers time and headaches associated with properly field-bending the high and low sides of metal building panels. We offer tools to accommodate all panel widths from 10 to 24 inches.

sheet metal hand hemming tool

maxwell house tastes like metal

may pvc conduit be attached to a steel box

matcor metal fabrication usa address

sheet metal edge finishing tool

Paint pretreatment process both sprays and immerses boxes for added corrosion protected; Drawer liners included at no extra charge; Gas struts in lid of chest make lid easy to open and .

hemming tool for sheet metal|seam joint in sheet metal