broaching on cnc machine zero point is After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool. $24.99

0 · single point broaching on lathe

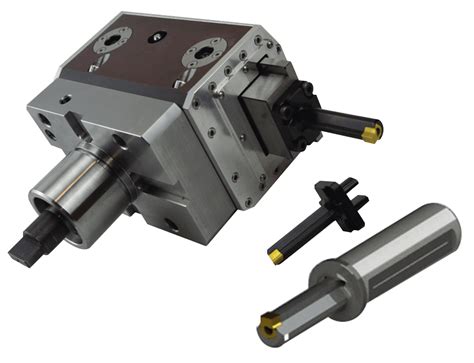

1 · live broaching machine center

2 · cnc broaching tolerances

3 · cnc broaching process

4 · cnc broaching inserts

5 · broaching on cnc lathe

6 · broaching machine centers

7 · broaching cnc mills

Metal Sheets, Bars, & Rods at Tractor Supply Co. Buy online, free in-store pickup. Shop today!

I've looked all over and I can't find anything that tells me how to program a broach on a C/Y lathe. I have a flywheel that I'm trying to program that has a keyway on a tapered bore that I want to single point broach. Analogous to the multiple passes of a shaper, a relatively new class of CNC tooling and programming allows broaching operations to be done without the need for a second operation, thus greatly increasingly quality . If you have thousands to make, rotary broach may be an option, but .950 Ø is a rather large spline for rotary broaching. You could get a push broach ground up and with the .Broaching operations canned cycle can be done on Inner and outer grooves in different position using the G156 code with an optional address codes which define the tool Pecks and the cut paths. Broaching operations canned cycle .

After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool.At an average of .001” Depth of Cut per pass there’s not enough impact to beat on your machine. This guide will walk you through the basic steps of what it takes to get a CNC machine .

CNC Lathe broaching and CNC mill broaching are great methods of completing the slotting process and avoiding the cost other expensive Broaching Systems. This guide will walk you through the basic steps of what it takes to get a CNC . Just use a sub-routine or a sub-program. Rotate to your location then call sub. In the main call for L55 6.4285, which will repeat the process 55 more times to complete 56 . Explore the essentials of spline broaching, including DIN, ANSI, standards. Learn how Fortune Machines and Tools can enhance your machining precision with custom . I've looked all over and I can't find anything that tells me how to program a broach on a C/Y lathe. I have a flywheel that I'm trying to program that has a keyway on a tapered bore that I want to single point broach.

Analogous to the multiple passes of a shaper, a relatively new class of CNC tooling and programming allows broaching operations to be done without the need for a second operation, thus greatly increasingly quality control and reducing time, space and cost. If you have thousands to make, rotary broach may be an option, but .950 Ø is a rather large spline for rotary broaching. You could get a push broach ground up and with the .600 length of cut, do them on an arbor press. rotary broaches require high thrusts, often see this done as a second op on a drill press. happen in opperators free time and avoids the wear on the cnc spindle. Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is .

I have broached blind keyways without a chip relief by programing a small radius (0.03") on the end of the broach stroke to sort of shear off the chip when the tool moves toward center. Small radius is usually not even noticed. If you can .

single point broaching on lathe

live broaching machine center

Broaching operations canned cycle can be done on Inner and outer grooves in different position using the G156 code with an optional address codes which define the tool Pecks and the cut paths. Broaching operations canned cycle can be done using a single tool path (with adjustable programmable Pecks) when using a special broaching shape tool. After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool.

At an average of .001” Depth of Cut per pass there’s not enough impact to beat on your machine. This guide will walk you through the basic steps of what it takes to get a CNC machine broaching your parts. TIP: The code examples used in the guide will .

CNC Lathe broaching and CNC mill broaching are great methods of completing the slotting process and avoiding the cost other expensive Broaching Systems. This guide will walk you through the basic steps of what it takes to get a CNC machine broaching your parts. I've looked all over and I can't find anything that tells me how to program a broach on a C/Y lathe. I have a flywheel that I'm trying to program that has a keyway on a tapered bore that I want to single point broach. Analogous to the multiple passes of a shaper, a relatively new class of CNC tooling and programming allows broaching operations to be done without the need for a second operation, thus greatly increasingly quality control and reducing time, space and cost.

If you have thousands to make, rotary broach may be an option, but .950 Ø is a rather large spline for rotary broaching. You could get a push broach ground up and with the .600 length of cut, do them on an arbor press. rotary broaches require high thrusts, often see this done as a second op on a drill press. happen in opperators free time and avoids the wear on the cnc spindle. Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is .

I have broached blind keyways without a chip relief by programing a small radius (0.03") on the end of the broach stroke to sort of shear off the chip when the tool moves toward center. Small radius is usually not even noticed. If you can .Broaching operations canned cycle can be done on Inner and outer grooves in different position using the G156 code with an optional address codes which define the tool Pecks and the cut paths. Broaching operations canned cycle can be done using a single tool path (with adjustable programmable Pecks) when using a special broaching shape tool. After each axis of the machine tool has a reference point, you can find the zero point of each axis, and the zero point of each axis will inevitably converge together, which is the zero point of the machine tool.

At an average of .001” Depth of Cut per pass there’s not enough impact to beat on your machine. This guide will walk you through the basic steps of what it takes to get a CNC machine broaching your parts. TIP: The code examples used in the guide will .

cnc broaching tolerances

knight rider metal lunch box

The Largest Inventory of Metal Fabrication Parts and Supplies. We replace and service the mechanical, electrical, and hydraulic parts of your fabrication machinery in order to keep metalworking machinery running smoothly.

broaching on cnc machine zero point is|cnc broaching process